Preparation method and application of carbon nitride ultrathin heterojunction

A heterojunction, carbon nitride technology, applied in chemical instruments and methods, nitrogen compounds, nitrogen and non-metallic compounds, etc., can solve the problem of low driving force of oxidation/reduction reaction, full water splitting performance needs to be improved, carrier Problems such as slow transmission, to avoid environmental pollution problems, cheap raw materials, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

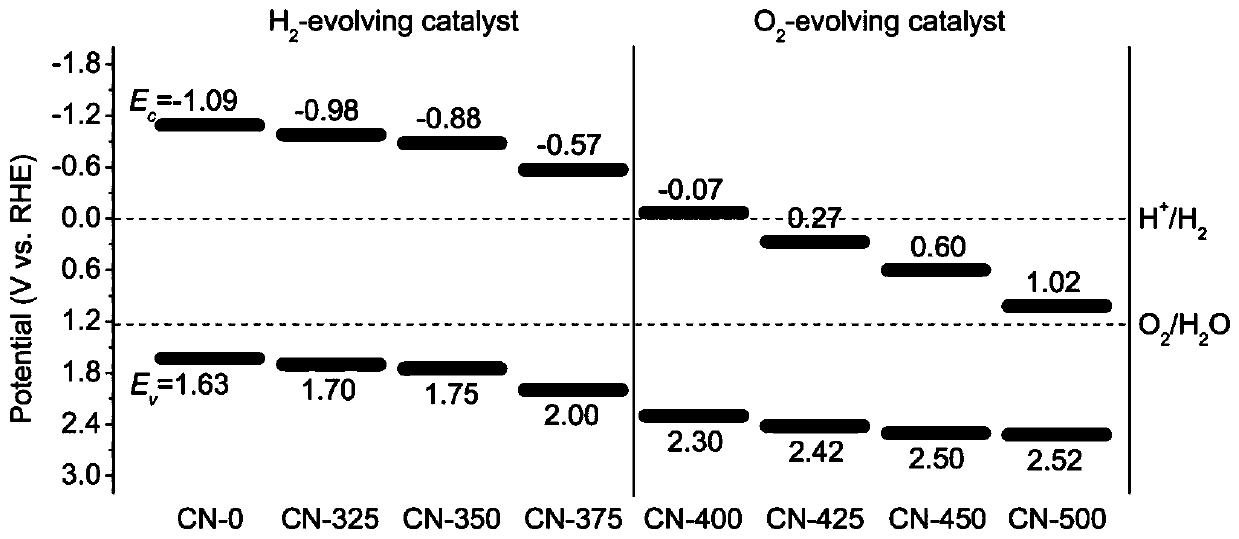

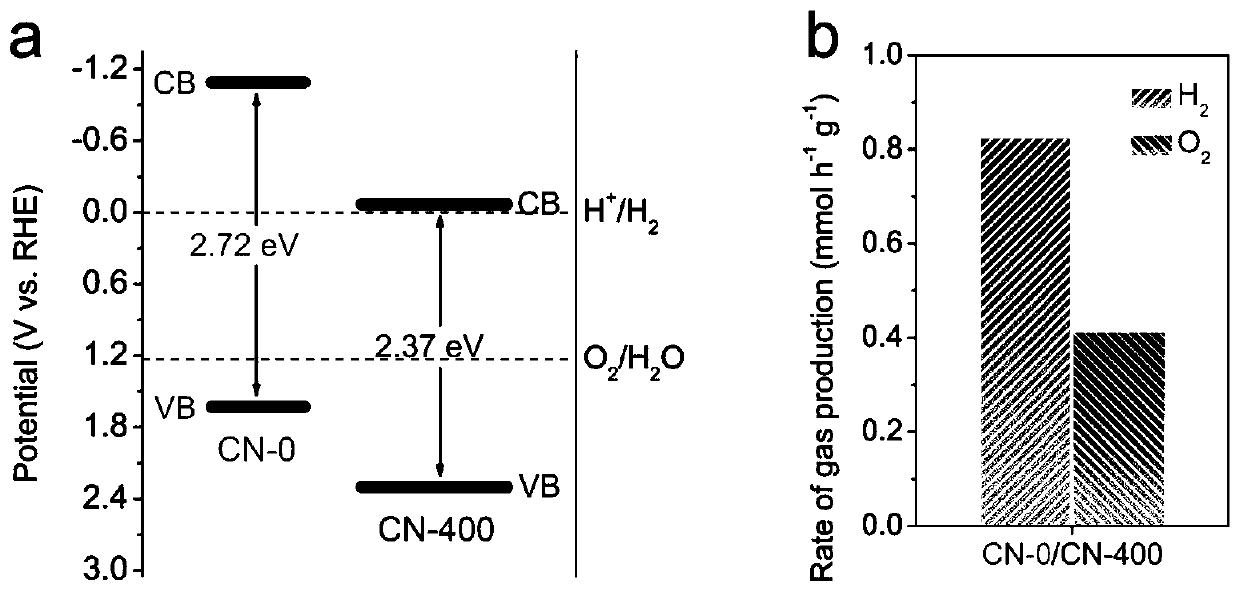

[0037] 1), such as figure 2 As shown in a, 0.5 g of negatively charged ultrathin hydrogen-producing g-C 3 N 4 (CN-0) was added to 200 mL of aqueous hydrochloric acid solution with a concentration of 1.5 mol / L, followed by ultrasonication for 1 h, stirring vigorously at a speed of 700 r / min for 4 h, then filtering and washing until the supernatant was neutral, and finally vacuum drying to remove water;

[0038] 2), 0.05g negatively charged ultra-thin oxygen-producing g-C 3 N 4 (CN-400) and 0.05g of the positively charged ultrathin hydrogen-producing g-C obtained in step 1) 3 N 4 (CN-0) was added to 200mL deionized water, followed by ultrasonication for 0.5h and vigorous stirring at a speed of 700r / min for 4h. Finally, the water was removed by rotary evaporation to obtain the target product carbon nitride ultrathin heterojunction. The photolytic water splitting performance such as figure 2 as shown in b.

Embodiment 2

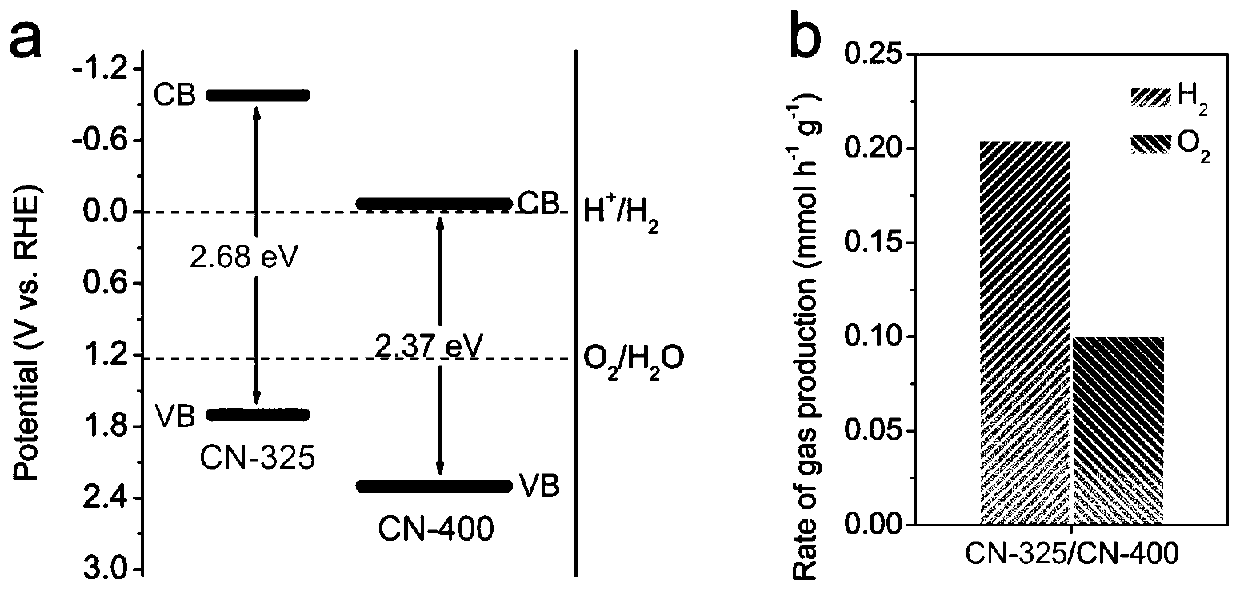

[0040] 1), such as image 3 As shown in a, 0.4 g of negatively charged ultrathin hydrogen-producing g-C 3 N 4 (CN-325) was added to 200mL of 1.5mol / L aqueous hydrochloric acid solution, ultrasonically ultrasonicated for 1h, stirred vigorously at a speed of 800r / min for 3h, then filtered and washed until the supernatant was neutral, and finally vacuum-dried to remove water;

[0041] 2), 0.1g negatively charged ultra-thin oxygen-producing g-C 3 N 4 (CN-400) and 0.1 g of the positively charged ultrathin hydrogen-producing g-C obtained in step 1) 3 N 4 (CN-325) was added to 200mL deionized water, followed by ultrasonication for 0.5h and vigorous stirring at a speed of 800r / min for 3h. Finally, the water was removed by rotary evaporation to obtain the target product carbon nitride ultra-thin heterojunction. This heterojunction The photolytic water splitting performance such as image 3 as shown in b.

Embodiment 3

[0043] 1), such as Figure 4 As shown in a, 0.6 g of negatively charged ultrathin hydrogen-producing g-C 3 N 4 (CN-375) was added to 250 mL of aqueous hydrochloric acid solution with a concentration of 1.5 mol / L, ultrasonically for 1 h, and vigorously stirred at a speed of 800 r / min for 4 h, then filtered and washed until the supernatant was neutral, and finally vacuum-dried to remove water;

[0044] 2), 0.1g negatively charged ultra-thin oxygen-producing g-C 3 N 4 (CN-450) and 0.1 g of the positively charged ultrathin hydrogen-producing g-C obtained in step 1) 3 N 4 (CN-375) was added to 250mL of deionized water, followed by ultrasonication for 0.5h and vigorous stirring at a speed of 800r / min for 4h. Finally, the water was removed by rotary evaporation to obtain the target product carbon nitride ultrathin heterojunction. This heterojunction The photolytic water splitting performance such as Figure 4 as shown in b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com