Black phosphorus loaded tungsten nitride nanosheet photocatalyst as well as preparation method and application thereof

A tungsten nitride nano-catalyst technology, applied in the field of photocatalytic materials, can solve the problems of poor light response, poor hydrogen evolution performance of photolysis water, easy reorganization of photogenerated carriers, etc., and achieves the effect of promoting transfer and facilitating charge transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

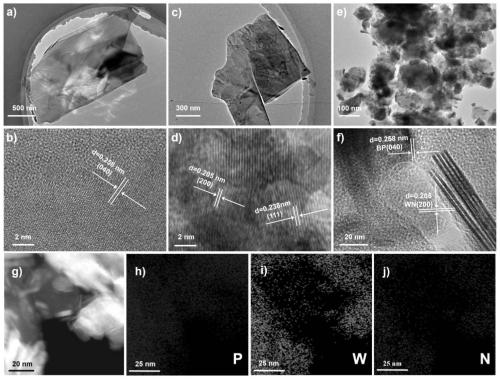

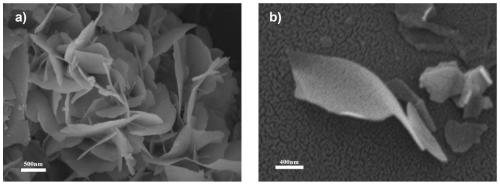

[0105] A black phosphorus-supported tungsten nitride nanosheet photocatalyst mainly contains three main elements of P, W and N, and is prepared by a method comprising the following steps:

[0106] (1), preparation of black phosphorus (hereinafter referred to as BP) crystal

[0107] First, red phosphorus was added to deionized water, and the resulting solution was transferred into a Teflon-lined stainless steel autoclave and hydrothermally heated at 180 °C for 20 h under hydrothermal reaction conditions to remove the oxide layer. Then, 500 mg of red phosphorus (RP) after hydrothermal treatment, 20 mg of tin powder (Sn) and tin tetraiodide (SnI 4 ) 10mg sealed in a vacuumized quartz glass tube. We heated the quartz glass tube at a rate of 0.1-3 °C per minute to 650 °C for 5 hours and then cooled it to 500 °C at a rate of 1.35 °C / min, followed by natural cooling. The resulting product needs to be washed several times with hot toluene and acetone to remove excess mineralizer, dr...

Embodiment 2

[0119] The hydrogen evolution performance of the obtained black phosphorus-supported tungsten nitride nanosheet photocatalyst sample was tested.

[0120] Weigh 10mg of the Bulk-BP, BP-BM, WN obtained in the above steps (1)(2)(3) and the BP-BM / WN finally obtained in the step (4) respectively in the sample bottle, and add 10mL respectively to remove Ionized water, and then control the power to 60W, the frequency is 40KHz to carry out ultrasonication for 10 minutes, then use argon to exhaust, and after exhausting for 2 hours, put it under the irradiation of 300W xenon lamp (with 420nm cut-off filter or 700nm cut-off filter) Hydrogen production test.

[0121] The above black phosphorus-supported tungsten nitride nanosheet photocatalyst is used for photocatalytic water splitting to produce hydrogen, and its dosage as a catalyst is 10 mg. Depend on Figure 5 In a, under >420nm light, the hydrogen production rate of catalytic water splitting for 5 hours is 9.42 μmol, and the hydrog...

Embodiment 3

[0125] The photoelectric properties of the obtained black phosphorus-supported tungsten nitride nanosheet photocatalyst samples were tested.

[0126] Mix 7.5mg of photocatalyst, 1mg of ethyl cellulose, 1mL of α-terpineol, and 0.5mL of ethanol, and then control the power to 60W and frequency of 40KHz to perform ultrasonication for 12h to obtain a slurry; the slurry obtained above is coated on On the FTO glass, the coating thickness is controlled to be 0.5-1mm, and dried in an oven at 60°C to obtain a working electrode for electrochemical testing, which is then tested at an electrochemical workstation for photoelectrochemical performance.

[0127] BP-BM / WN represents the resulting black phosphorus-supported tungsten nitride nanosheet photocatalyst, from Figure 6 In a and 6b, it can be seen that when the lamp is turned off, no current is generated, and when the lamp is turned on, a photocurrent is generated, which indicates that the photogenerated electron-hole pairs of BP-BM / WN...

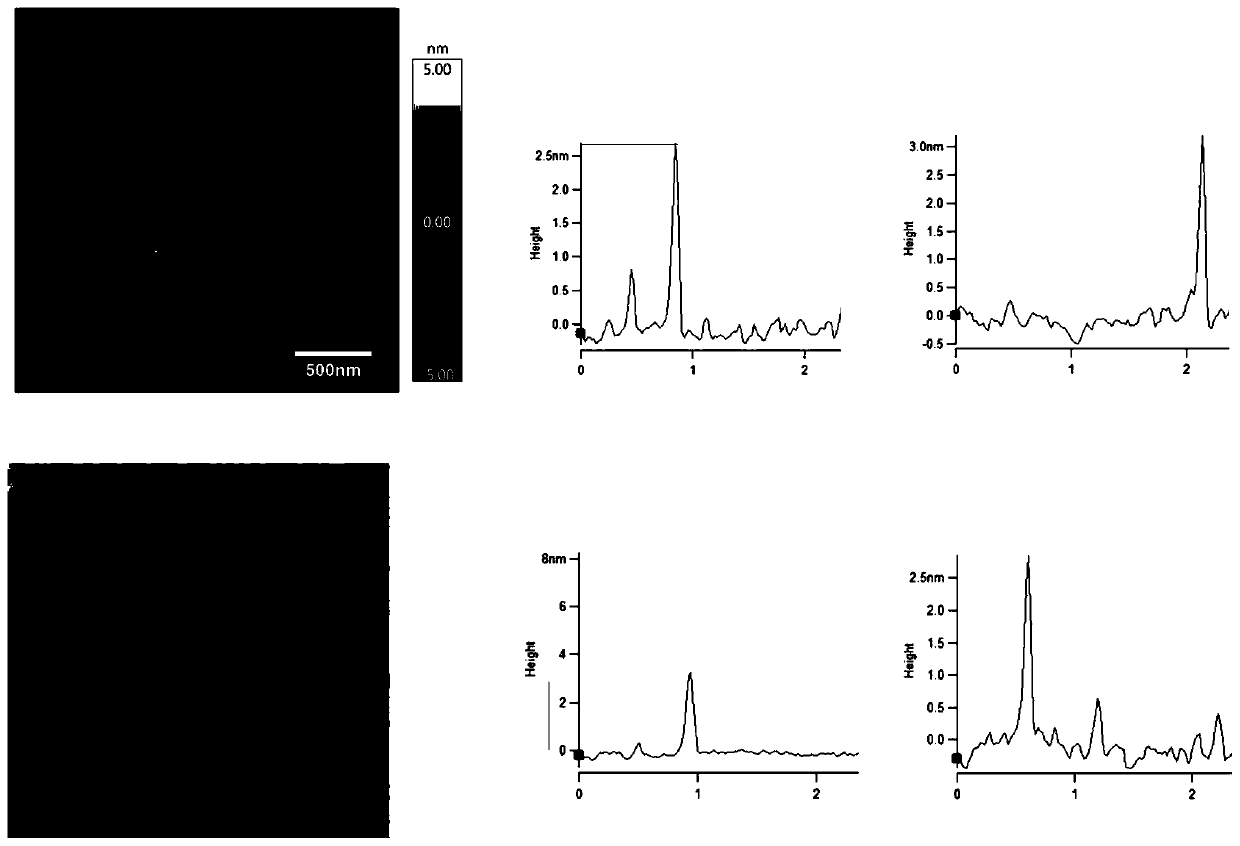

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com