Method for preparing hydroxyapatite ceramic through combination of microwave hydrothermal method and microwave sintering method

A technology of hydroxyapatite and microwave hydrothermal method, which is applied in medical science, prosthesis, tissue regeneration, etc., can solve the problem of poor mechanical properties of hydroxyapatite ceramics, abnormal growth of crystal grains, and low bending strength. Advanced problems, to achieve the effect of shortening sintering time, high density and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

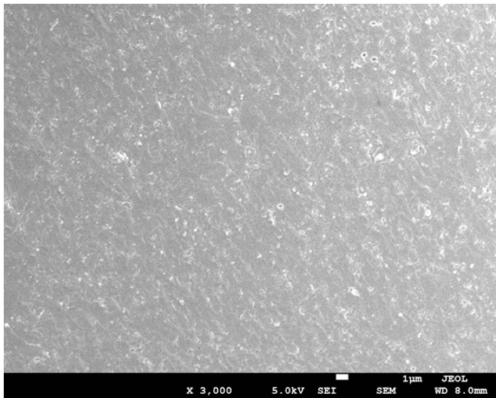

[0018] Dissolve 14.32 g of disodium hydrogen phosphate and 9.8 g of calcium chloride dihydrate in 100 mL of pure water, respectively, and stir magnetically for about 20 minutes until the samples are completely dissolved to obtain disodium hydrogen phosphate aqueous solution and calcium chloride aqueous solution. Slowly spray the prepared calcium chloride aqueous solution into the disodium hydrogen phosphate aqueous solution by ultrasonic spraying method, the rotating speed of the magnetic stirrer is 5 r / min, and the liquid spraying speed is 10 mL / min. During the ultrasonic spraying process, ammonia water was continuously added dropwise to the reaction solution, and the pH of the mixed solution was adjusted to keep it at about 10. The mixed reaction solution was placed in a microwave reactor for reaction, the heating rate was set at 10°C / min, the reaction temperature was 160°C, and the holding time was 40min. After the reaction was completed, the hydroxyapatite solution was obt...

Embodiment 2

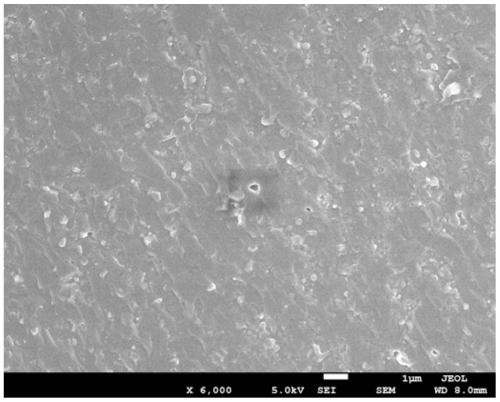

[0022] Dissolve 14.32 g of disodium hydrogen phosphate and 9.8 g of calcium chloride dihydrate in 100 mL of pure water, respectively, and stir magnetically for about 20 minutes until the samples are completely dissolved to obtain disodium hydrogen phosphate aqueous solution and calcium chloride aqueous solution. Slowly spray the prepared calcium chloride aqueous solution into the disodium hydrogen phosphate aqueous solution by ultrasonic spraying method, the rotating speed of the magnetic stirrer is 5 r / min, and the liquid spraying speed is 10 mL / min. During the ultrasonic spraying process, ammonia water was continuously added dropwise to the reaction solution, and the pH of the mixed solution was adjusted to keep it at about 10. The mixed reaction solution was placed in a microwave reactor for reaction, the heating rate was set at 10°C / min, the reaction temperature was 160°C, and the holding time was 40min. After the reaction was completed, the hydroxyapatite solution was obt...

Embodiment 3

[0025] Dissolve 14.32 g of disodium hydrogen phosphate and 9.8 g of calcium chloride dihydrate in 100 mL of pure water, respectively, and stir magnetically for about 20 minutes until the samples are completely dissolved to obtain disodium hydrogen phosphate aqueous solution and calcium chloride aqueous solution. Slowly spray the prepared calcium chloride aqueous solution into the disodium hydrogen phosphate aqueous solution by ultrasonic spraying method, the rotating speed of the magnetic stirrer is 5 r / min, and the liquid spraying speed is 10 mL / min. During the ultrasonic spraying process, ammonia water was continuously added dropwise to the reaction solution, and the pH of the mixed solution was adjusted to keep it at about 10. The mixed reaction solution was placed in a microwave reactor for reaction, the heating rate was set at 10°C / min, the reaction temperature was 160°C, and the holding time was 40min. After the reaction was completed, the hydroxyapatite solution was obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com