Combined technique for producing high-end graphite carbon material

A kind of graphite carbon, high-end technology, applied in the field of combination process of high-end graphite carbon materials, can solve problems such as large performance gap and unfavorable industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

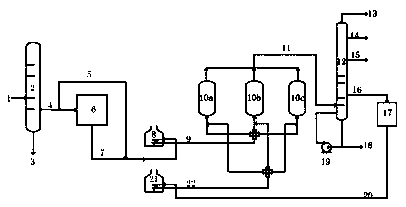

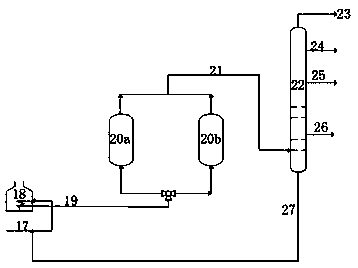

Method used

Image

Examples

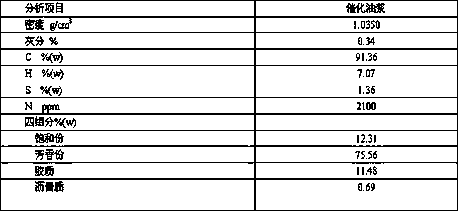

Embodiment 1

[0087] Catalytic oil slurry from a certain refinery is used as raw material. See Table 1 for the analysis of the specific properties of the oil slurry. The raw material inlet temperature of the vacuum deep-drawing tower is 375°C, the temperature at the top of the tower is 80°C, the absolute pressure at the top of the tower is 20mmHg, and the temperature at the bottom of the tower is The temperature is 400°C; the catalyst for hydrotreating unit adopts CEN, FZC, ZTN, ZTS series residual oil hydrogenation catalyst produced by Sinopec Catalyst Branch Company, including protective agent, demetallization catalyst, desulfurization catalyst and denitrogenation catalyst etc., the loading sequence is generally to make the raw material oil contact with the protective agent, hydrodemetallization, hydrodesulfurization, and hydrodenitrogenation catalysts in sequence. Of course, there is also a technology of mixing and loading these catalysts. The above-mentioned catalyst loading technology i...

Embodiment 2

[0098] Using the same device and raw material as in Example 1, the same vacuum deep drawing and hydrotreating process conditions, the coking raw material is hydrotreated oil and vacuum deep drawing light distillate mixed oil, the mixing ratio is 1:1, and the coking tower The top pressure is 0.6MPa, and the coking cycle of coking is 36h. According to the operation of the three-tower switching method provided by the present invention, when the coke charging time of the oil slurry coke tower accounts for 50% of the total coke charging time, switch to coking light wax oil and continue Charging, wherein, in step (1), the outlet temperature of heating furnace 1 is 420°C-450°C heating-constant temperature process, the heating rate is 5°C / h, the constant temperature time is 12h, and the gas velocity in the coke tower is controlled at 0.05-0.08m / s, the outlet temperature of the heating furnace 2 in step (2) is 470°C-490°C heating-constant temperature process, the heating rate is 10°C / h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com