Technique for producing high-end graphite carbon material

A graphite carbon, high-end technology, applied in the field of production of high-end graphite carbon materials, can solve the problems of unresolved needle coke operation fluctuations, unstable performance of needle coke products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

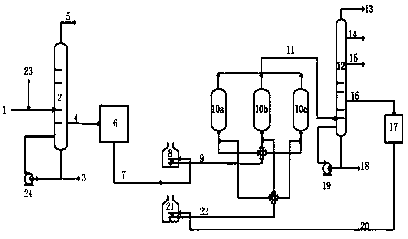

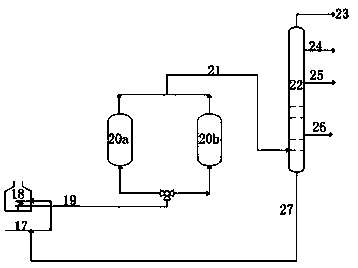

Method used

Image

Examples

Embodiment 1

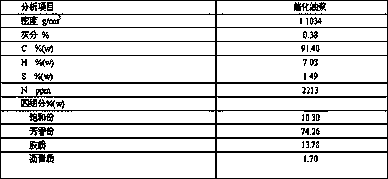

[0090] Catalytic oil slurry from a refinery was used as raw material, and the specific property analysis of the oil slurry is shown in Table 1.

[0091] The temperature of the 90% distillation point of the light distillate oil on the tower of the vacuum deep drawing device is 360°C, the temperature of the 10% distillation point of the heavy distillate oil at the bottom of the tower is 480°C, and the mixing mass ratio of the raw material to the vacuum residue is 1:0.5. The temperature of the 10% distillation point of the pressed residue is 500°C, and the heavy distillate is circulated at the bottom of the fractionating tower to control the temperature at the bottom of the fractionating tower to be 355°C. No abnormality was found until 30 days after the device was started.

[0092] Hydrotreating unit catalysts adopt CEN, FZC, ZTN, ZTS series residual oil hydrogenation catalysts produced by Sinopec Catalyst Branch Company, including protective agents, demetallization catalysts, d...

Embodiment 2

[0109] Catalytic oil slurry from a refinery was used as raw material, and the specific property analysis of the oil slurry is shown in Table 6.

[0110] The temperature of the 90% distillation point of the light distillate oil on the tower of the vacuum deep drawing device is 390°C, the temperature of the 10% distillation point of the heavy distillate oil at the bottom of the tower is 500°C, and the mixing mass ratio of the raw material to the vacuum residue is 1:2.0. The temperature of the 10% distillation point of the pressed residue is 550°C. The heavy distillate is circulated at the bottom of the fractionating tower to control the bottom temperature of the fractionating tower to be 320°C. No abnormality was found until 30 days after the device was started.

[0111] Hydrotreating unit catalysts adopt CEN, FZC, ZTN, ZTS series residual oil hydrogenation catalysts produced by Sinopec Catalyst Branch Company, including protective agents, demetallization catalysts, desulfurizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com