Countercurrent suspension type oven

A suspension type, oven technology, applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of extraction, low drying efficiency, large overprinting error, etc., to ensure overprinting accuracy and improve drying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the construction principle of the present invention will be further described according to the above description and accompanying drawings.

[0024] The countercurrent suspension oven includes two parts, the left half oven 1 and the right half oven 2, which are relatively closed together during operation, and the printing film 20 passes through the gap between the left and right half ovens.

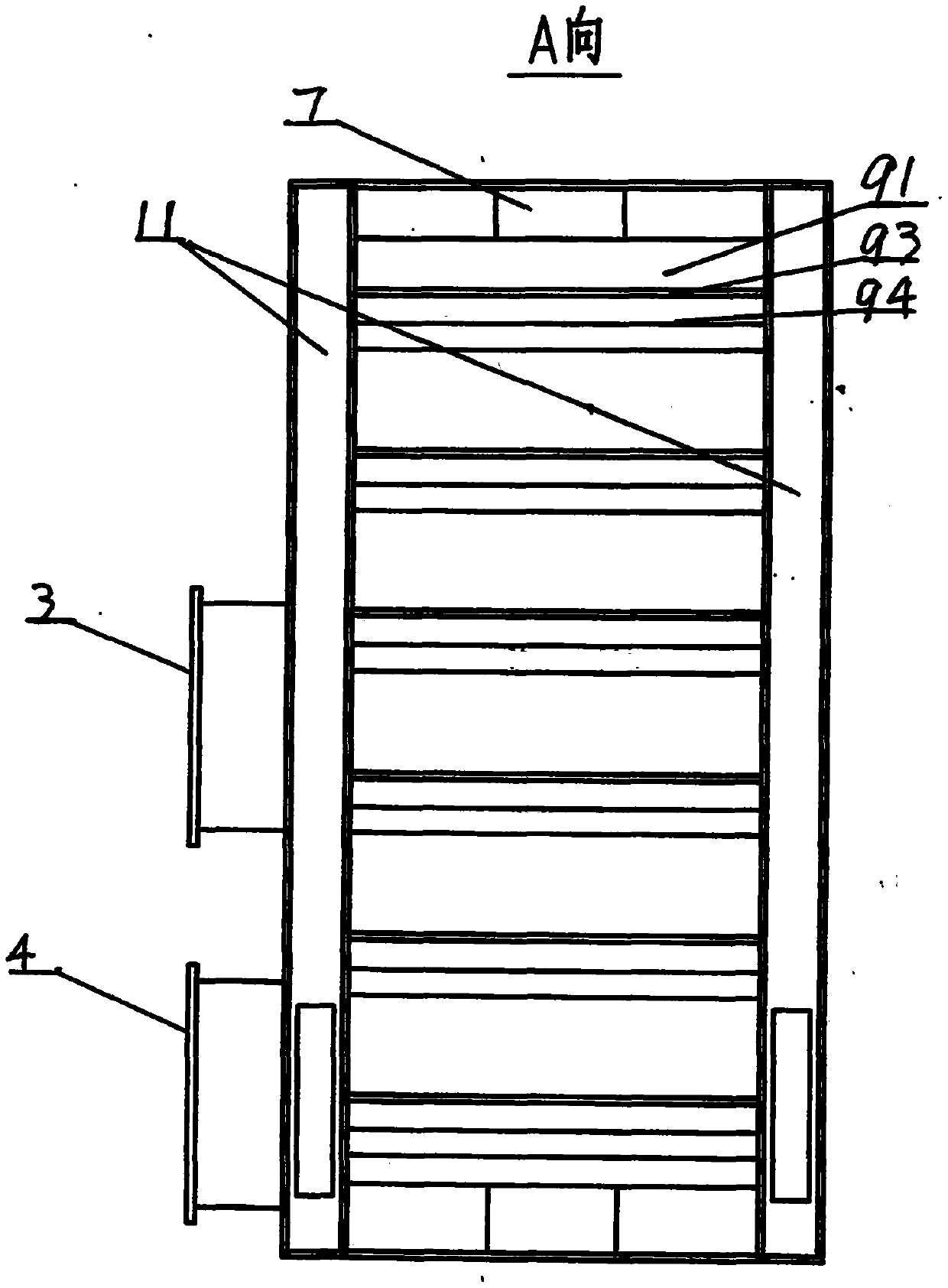

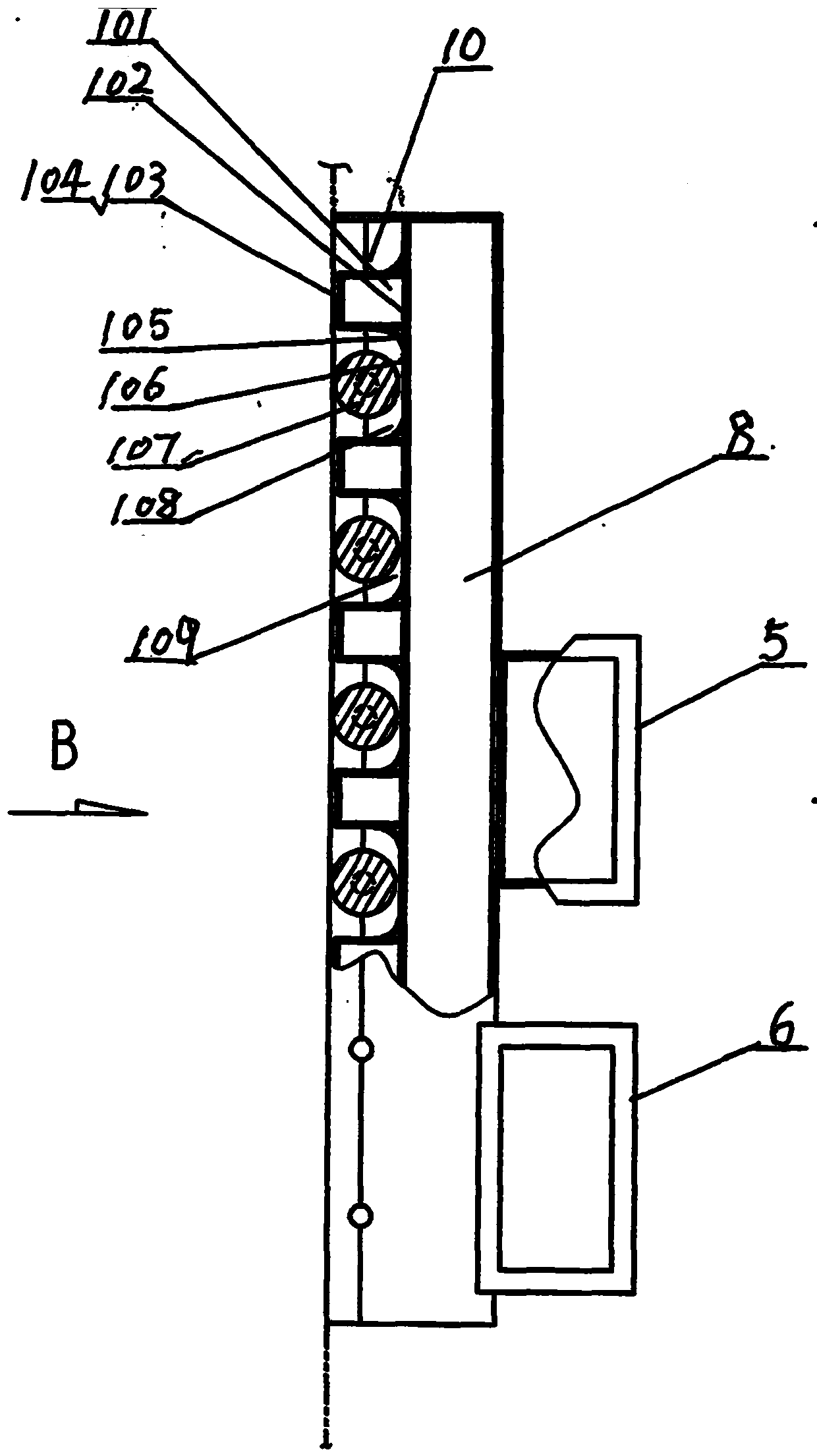

[0025] The structure of the left half oven 1 includes, from the outside to the inside, the first main air inlet pipe 3 and the first main exhaust pipe 4 arranged horizontally, the first middle air inlet pipe 7 arranged vertically and its two sides The first row of air ducts 11, and the blowing ducts 91, wind shovels 93, wind deflectors 94 and exhaust gas guide pipes 95 arranged horizontally and connected to each other. The two ends of the waste gas guide pipe are respectively plugged with the first exhaust pipes 11 on both sides. The air inlet 92 at the top of the blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com