Low-temperature lead-free solder paste and preparation method thereof

A lead-free solder paste, low-temperature technology, applied in the direction of welding equipment, manufacturing tools, welding media, etc., can solve the problems of solder wettability, poor tensile and shear performance, etc., to achieve improved drop resistance and thermal cycle life Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also discloses a preparation method of low-temperature lead-free solder paste, comprising the following steps:

[0044] (1) Weigh rosin, thixotropic agent, active agent and solvent in proportion.

[0045] (2) Add solvent into the container, heat up to 150-160°C, add rosin and stir until completely melted, then add thixotropic agent and stir until completely melted.

[0046] (3) Cool down the above system to 120-130°C, then add active agent, stir until completely melted, cool to get paste flux, put it in 0-10°C freezer for future use.

[0047] (4) Weigh low-temperature tin-bismuth-silver-copper quaternary lead-free solder powder and flux in proportion, pour them into a vacuum mixer, stir initially at low speed for 5-10 minutes, then fill with nitrogen and stir at medium speed for 25-35 minutes, so that Thoroughly mix tin powder and flux, and then vacuumize and stir at medium speed for 5 to 7 minutes to prepare solder paste.

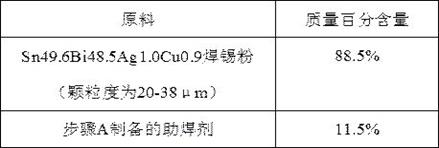

Embodiment 1

[0050] A. Prepare a flux with the following ratio:

[0051]

[0052] The preparation method is as follows:

[0053] Weigh 23% by mass of polymerized rosin, 24% by mass of hydrogenated rosin, 4% by mass of modified hydrogenated castor oil, 3% by mass of ethylene bis stearic acid amide , 36.2% by mass of diethylene glycol hexyl ether and 3% by mass of succinic acid, 3% by mass of adipic acid, 0.3% by mass of diphenylguanidine hydrobromide Salt, 3.5% by mass of benzotriazole; add solvent to stainless steel container and heat to 160°C, add rosin and stir until completely melted, keep this temperature and add thixotropic agent and stir until completely melted; cool down to 130°C ℃, 3% by mass of succinic acid, 3% by mass of adipic acid and 0.3% by mass of diphenylguanidine hydrobromide are added to the container, and stirred until completely melted, Finally, 3.5% by mass of benzotriazole was added and stirred to melt. After cooling, the flux is obtained, and stored in a 7°C f...

Embodiment 2

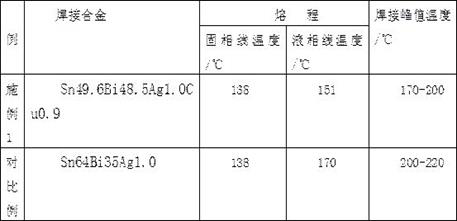

[0061] Prepare a solder paste with the following ratio:

[0062]

[0063] The preparation method is as follows:

[0064] 87.5% by mass of Sn49.6Bi48.5Ag1.0Cu0.9 solder powder was poured into a vacuum mixer filled with nitrogen and stirred at a low speed for 5 minutes.

[0065] Then weigh 12.5% by mass of flux, add it to the above mixed solder powder, stir in a vacuum mixer at low speed for 5 minutes, then fill with nitrogen and stir at medium speed for 30 minutes, so that the tin powder and flux are fully mixed Evenly, then evacuate and stir at medium speed for 5 minutes to prepare solder paste.

[0066] This solder paste is applied to remote control PCB board soldering, placed in an air reflow oven with a peak temperature of 175°C, no damage to the LED lamp, and full tin on the plug-in position, all tests meet the customer's process control requirements.

[0067] Classification of existing soldering processes and maximum reflow temperatures in the electronics assembly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com