Photocatalyst suitable for dark light indoor air purification

A technology of indoor air and photocatalyst, applied in the field of photocatalyst, can solve the problems of discounted sterilization effect and no reports, etc., and achieve the effect of improving efficiency, good sterilization, and good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

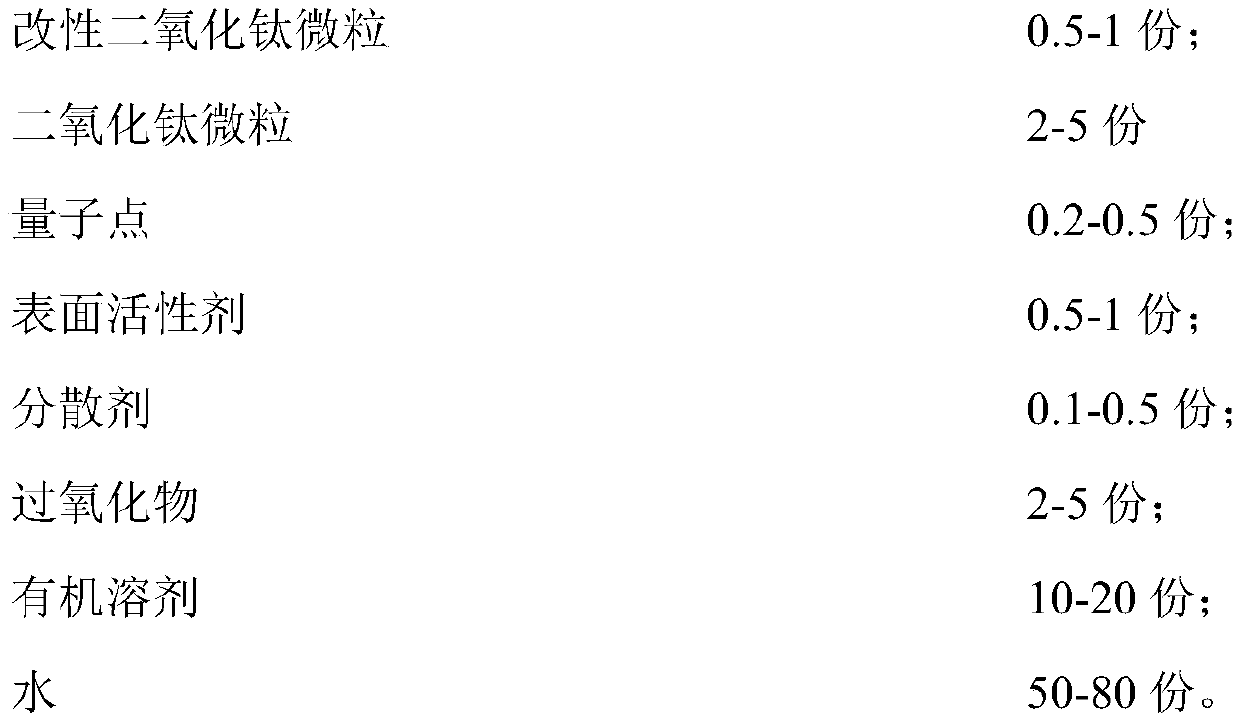

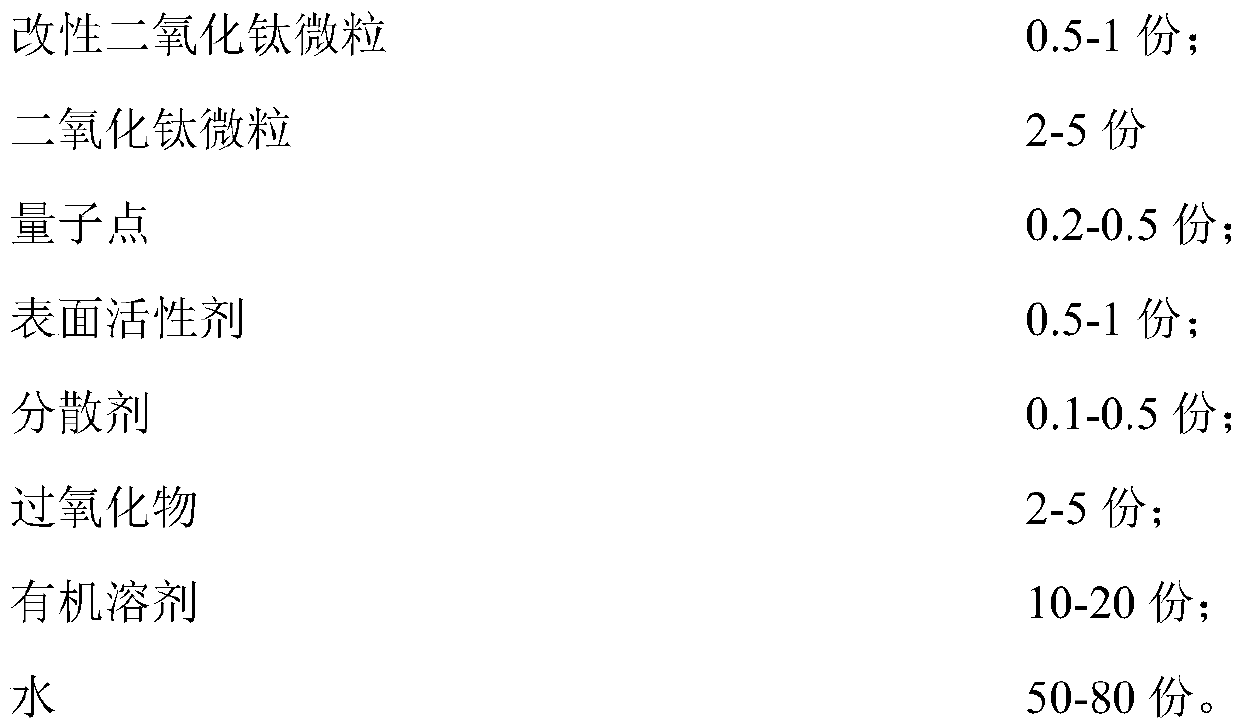

Method used

Image

Examples

preparation example 1

[0027] The preparation method of modified titanium dioxide particle 1 comprises the steps:

[0028] S1. Add 1mmol of vinyl cage silsesquioxane, 25ml of acetic acid and 0.003mmol of concentrated sulfuric acid to 50ml of chloroform, then raise the temperature to 60°C, then add 30ml of hydrogen peroxide to it, reflux for 12h, and then use dichloro Methane extraction, organic phase vacuum distillation, to obtain intermediate products;

[0029] S2. Dissolve the intermediate product in 20ml of THF, then add 8mmol of titanium dioxide particles, and 1ml of 30wt% NaOH solution, react at 30°C for 4h, then add 3ml of concentrated hydrochloric acid to quench the reaction, then add 300ml of water to stir, filter and The filter residue was collected and dried in vacuo to obtain the product, yield = 82%.

preparation example 2

[0031] The preparation method of modified titanium dioxide particle 2 comprises the steps:

[0032] S1. Add 1mmol of methacryl cage silsesquioxane, 25ml of acetic acid and 0.003mmol of concentrated sulfuric acid to 50ml of chloroform, then raise the temperature to 80°C, then add 30ml of hydrogen peroxide to it, reflux for 24h, and then Extracted with dichloromethane, and the organic phase was distilled under reduced pressure to obtain an intermediate product;

[0033] S2. Dissolve the intermediate product in 25ml of THF, then add 9mmol of titanium dioxide particles, and 1.3ml of 30wt% NaOH solution, react at 50°C for 8h, then add 3ml of concentrated hydrochloric acid to quench the reaction, then add 300ml of water and stir, filter The filter residue was collected and dried in vacuo to obtain the product with a yield of 82%.

preparation example 3

[0035] S1. Add 1mmol of vinyl cage silsesquioxane, 25ml of acetic acid and 0.003mmol of concentrated sulfuric acid to 50ml of chloroform, then raise the temperature to 50°C, then add 32ml of hydrogen peroxide to it, reflux for 18h, and then use dichloro Methane extraction, organic phase vacuum distillation, to obtain intermediate products;

[0036] S2. Dissolve the intermediate product in 20ml of THF, then add 10mmol of titanium dioxide particles, and 0.8ml of 30wt% NaOH solution, react at 30°C for 6h, then add 3ml of concentrated hydrochloric acid to quench the reaction, then add 280ml of water and stir, filter The filter residue was collected and dried in vacuo to obtain the product with a yield of 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com