Ammonia water working medium combined cooling heating and power system utilizing medium-low temperature heat source and working method thereof

A technology of combined cooling, heating and power supply and low-temperature heat source, which is applied in hot water central heating systems, heating systems, household heating, etc., and can solve problems such as low utilization rate, single utilization form of medium and low temperature heat sources, and inability to meet different needs , to achieve the effect of improving efficiency, improving energy utilization efficiency, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following describes the present invention in further detail with reference to the accompanying drawings and specific embodiments, the content of which is to explain rather than limit the present invention:

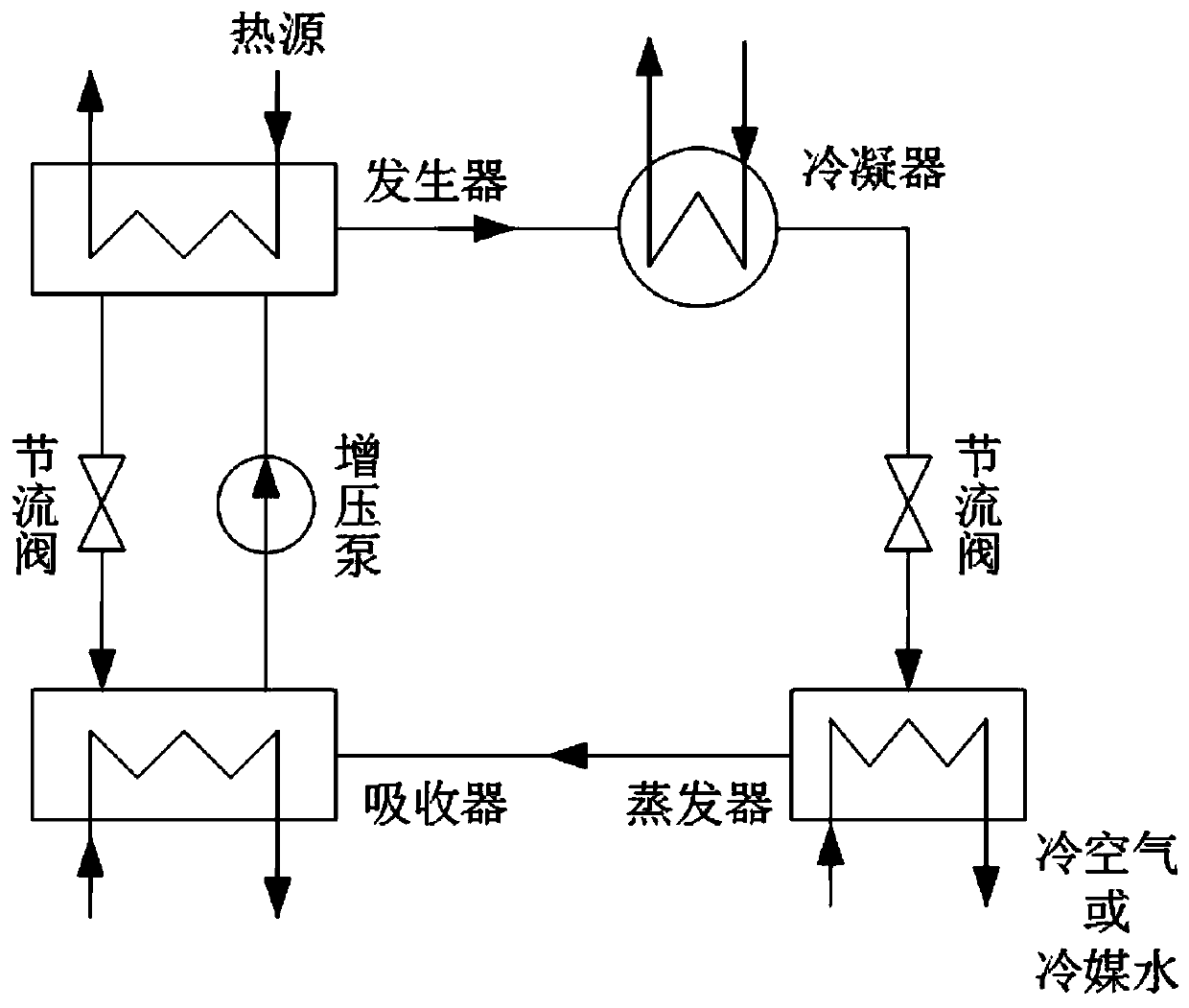

[0037] Figure 5 The ammonia water working medium combined cooling, heating and power system using medium and low temperature heat sources of the present invention includes a steam generator 1, an ammonia separator 2, a superheater 3, a turbine high-pressure cylinder 4, a turbine low-pressure cylinder 5, and a first condenser 8. Regenerator 10, rectification tower 11, absorber 14, second condenser 15, first evaporator 17, third condenser 18 and second evaporator 20;

[0038] The steam outlet of the ammonia separator 2 is connected to the turbine high pressure cylinder 4, the pipeline between the ammonia separator 2 and the turbine high pressure cylinder 4 is connected to the low temperature side of the superheater 3, and the turbine high pressure cylinder 4 and the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com