A kind of amphiphilic high temperature resistant silicon-based fiber plugging agent and preparation method thereof

A plugging agent, high temperature resistance technology, applied in fiber processing, chemical instruments and methods, textiles and papermaking, etc., can solve problems such as affecting the plugging effect, insufficient temperature resistance of the plugging agent, and inability to achieve the desired effect, etc. The production process is simple and easy to control, the effect of good plugging and anti-seepage effect, and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

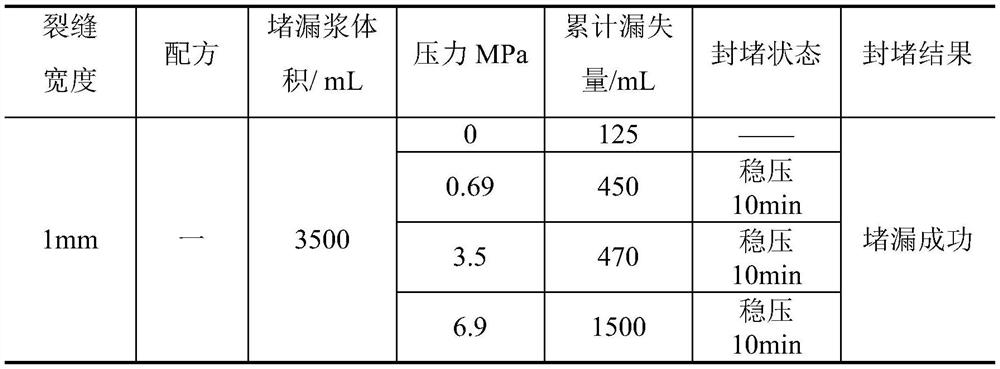

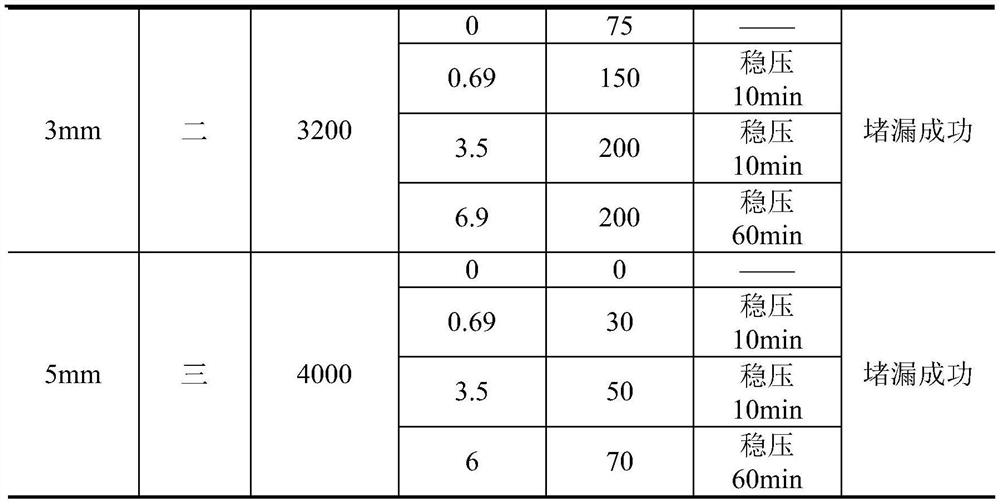

Examples

Embodiment 1

[0026] (1) silicon-based fiber preparation: ethyl orthosilicate 700g, calcium carbonate 150g, polyethylene glycol 150g are mixed in a kneader; add distilled water, stir rapidly, and adjust to a viscosity of 500mPa s; this solution is passed through The spinneret hole is sprayed into the coagulation bath of NaOH aqueous solution with a concentration of 1.0mol / L, and the temperature of the coagulation bath is controlled at 70 ℃, so that the ethyl orthosilicate in the prepolymer solution is hydrolyzed and polymerized, and then coagulated and formed;

[0027] (2) Surface modification of silicon-based fibers: 500 g of silicon-based fibers prepared in the above steps were dispersed in 1000 mL of distilled water, 100 g of β-cyclodextrin was added, and rapidly stirred to dissolve it completely; 50 mL of oxalic acid and 5 mL of sulfuric acid were incubated and reacted for 6 hours and then filtered, and the obtained fibers were washed twice with distilled water to obtain an amphiphilic h...

Embodiment 2

[0029] (1) Preparation of silicon-based fibers: 600 g of tetraethyl orthosilicate, 100 g of calcium carbonate, 150 g of polyethylene glycol, and 150 g of methyl cellulose are mixed well in a kneader; add distilled water, stir rapidly, and adjust to a viscosity of 4000 mPa. s; the solution is sprayed into the coagulation bath of NaOH aqueous solution with a concentration of 0.8 mol / L through the spinneret, and the temperature of the coagulation bath is controlled at 75 ° C, so that the ethyl orthosilicate in the prepolymer solution is hydrolyzed and polymerized, and coagulated and formed. ;

[0030] (2) Surface modification of silicon-based fibers: 500 g of silicon-based fibers prepared in the above steps were dispersed in 1000 mL of distilled water, 150 g of α-cyclodextrin was added, and 150 g of α-cyclodextrin was added to dissolve it completely; 60 mL of oxalic acid and 6 mL of sulfuric acid were incubated and reacted for 6 hours and then filtered, and the obtained fibers we...

Embodiment 3

[0032] (1) silicon-based fiber preparation: 800g of ethyl orthosilicate, 100g of polyvinyl alcohol, and 100g of methyl cellulose are mixed in a kneader; add distilled water, stir rapidly, and adjust to a viscosity of 8000mPa s; this solution It is sprayed into the coagulation bath of NaOH aqueous solution with a concentration of 0.8mol / L through the spinneret, and the temperature of the coagulation bath is controlled at 60°C, so that the ethyl orthosilicate in the prepolymer solution is hydrolyzed and polymerized, and coagulated and formed;

[0033] (2) Surface modification of silicon-based fibers: 500 g of silicon-based fibers prepared in the above steps were dispersed in 1000 mL of distilled water, 200 g of α-cyclodextrin was added, and rapidly stirred to completely dissolve; 80 mL of oxalic acid and 10 mL of sulfuric acid were incubated and reacted for 6 hours, filtered, and the obtained fiber was washed twice with distilled water to obtain an amphiphilic high-temperature re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com