Method for preparing inert porcelain ball by using aluminum oxide dust-recovery powder

A technology of inert ceramic balls and alumina balls, applied in the field of new materials, can solve the problems of high price and high price, and achieve the effects of improving thermal shock resistance and strength, low energy consumption and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

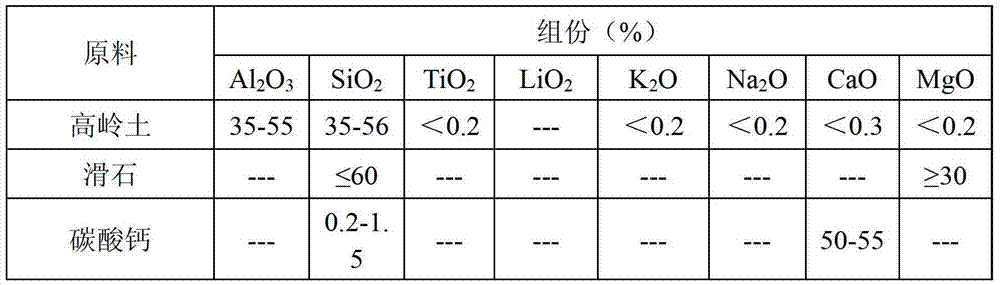

Method used

Image

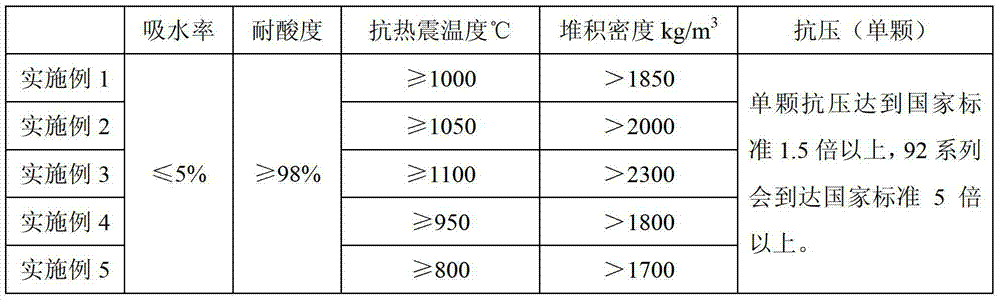

Examples

Embodiment 1

[0029] (1) Obtain the accurate proportioning of each raw material meeting the requirements respectively by weight.

[0030] The raw material ratio of the inert ceramic ball is (parts by weight): alumina dust collection powder: kaolin: calcium carbonate: talc: spodumene = 87 parts: 10 parts: 1 part: 1 part: 1 part.

[0031] (2) Put the alumina dust collection powder, kaolin and composite sintering aid into a continuous ball mill for dry grinding, use alumina ball stone as the grinding medium, the cylinder of the ball mill is 7.48m long, and the cylinder diameter is 1.5m. Materials: Ball = 1:2.5, discharge 4 tons per hour, then pass through a 250-mesh sieve, and electromagnetically remove iron to obtain a mixture.

[0032] (3) Homogenize the mixture obtained in step (2) through a homogenization bin.

[0033] (4) Roll the homogenized material powder obtained in step (3) through a ball forming machine to obtain a semi-finished ball blank of the required size. During the spheroid...

Embodiment 2

[0037] (1) Obtain the accurate proportioning of each raw material meeting the requirements respectively by weight.

[0038] The raw material ratio of the inert ceramic ball is (parts by weight): alumina dust collection powder: kaolin: calcium carbonate: talc: spodumene = 89 parts: 9 parts: 0.5 parts: 0.8 parts: 0.7 parts.

[0039] (2) Put the alumina dust collection powder, kaolin and composite sintering aid into a continuous ball mill for dry grinding, use alumina ball stone as the grinding medium, the cylinder of the ball mill is 7.48m long, and the cylinder diameter is 1.5m. Materials: Ball = 1:3, discharge 5 tons per hour, then pass through a 250-mesh sieve, electromagnetic iron removal to obtain the mixture.

[0040] (3) Homogenize the mixture obtained in step (2) through a homogenization bin.

[0041] (4) Roll the homogenized material powder obtained in step (3) through a ball forming machine to obtain a semi-finished ball blank of the required size. During the spheroi...

Embodiment 3

[0045] (1) Obtain the accurate proportioning of each raw material meeting the requirements respectively by weight.

[0046] The raw material ratio of the inert ceramic ball is (parts by weight): alumina dust collection powder: kaolin: calcium carbonate: talc: spodumene = 90 parts: 7 parts: 0.5 parts: 0.8 parts: 1.7 parts.

[0047] (2) Put the alumina dust collection powder, kaolin and composite sintering aid into a continuous ball mill for dry grinding, use alumina ball stone as the grinding medium, the cylinder of the ball mill is 7.48m long, and the cylinder diameter is 1.5m. Materials: Ball = 1:2.8, discharge 4.5 tons per hour, then pass through a 250-mesh sieve, and electromagnetically remove iron to obtain a mixture.

[0048] (3) Homogenize the mixture obtained in step (2) through a homogenization bin.

[0049] (4) Roll the homogenized material powder obtained in step (3) through a ball forming machine to obtain a semi-finished ball blank of the required size. During th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com