Preparation method of flower-shaped molybdenum disulfide nano-rods

A technology of molybdenum disulfide and nanorods, which is applied in the field of nanomaterials, can solve the problems of complex process, high cost, and impact on large-scale application, and achieve the effects of high product yield, simple and easy-to-control production process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 0.4g benzyltriethylammonium chloride and 0.42g Pluronic F-127 in 60mL of deionized water, then add 0.88g sodium molybdate, 1.40g sodium sulfide, and 0.6g glucose, after completely dissolving , and then adjust the pH value to about 6 with 2mol / L HCl; after stirring for 30min, transfer the mixture to a 100mL stainless steel reaction kettle, place it in a vacuum oven at 160°C for 24h, and cool to room temperature. After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol, and finally dried at 60° C. for 12 hours under vacuum to obtain a gray-black powder product, namely molybdenum disulfide flower-like nanorods.

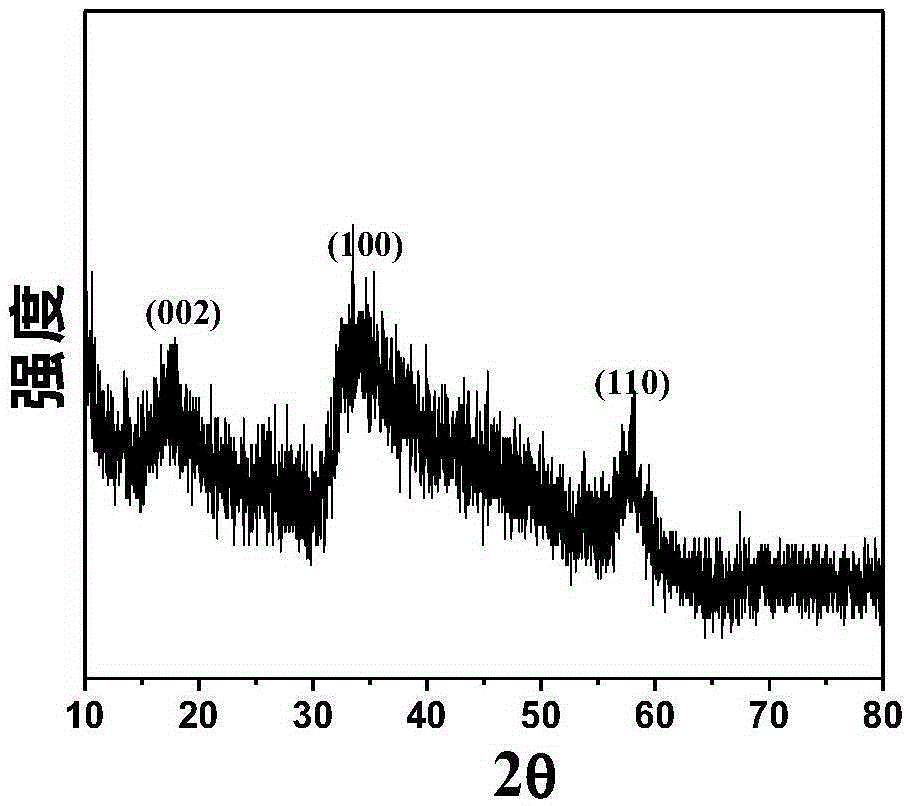

[0021] figure 1 The XRD pattern shows that the XRD peak position is consistent with the standard diffraction pattern (PDFNo.37-1492), and the product is a pure molybdenum disulfide nanostructure. figure 2 The SEM photo of the product shows the existence of a large number of flower-lik...

Embodiment 2

[0023] Dissolve 0.4 g of benzyltriethylammonium chloride and 0.63 g of Pluronic F-127 in 60 mL of deionized water, then add 0.88 g of sodium molybdate, 1.40 g of sodium sulfide and 0.6 g of glucose. After complete dissolution, adjust the pH value to about 6 with 2mol / L HCl; after stirring for 30 minutes, transfer the mixture to a 100mL stainless steel reaction kettle, place it in a vacuum drying oven at 180°C for 24 hours, and cool to room temperature; After the reaction product was separated by centrifugation, it was washed repeatedly with deionized water and absolute ethanol, and finally dried at 60° C. for 12 hours under vacuum to obtain a gray-black powder product, namely molybdenum disulfide flower-like nanorods. The obtained molybdenum disulfide flower-like nanorod has a diameter of 200-500 nm and a length of 1-2 μm.

Embodiment 3

[0025] Dissolve 0.4 g of benzyltriethylammonium chloride and 0.26 g of sodium dodecylbenzenesulfonate in 60 mL of deionized water, then add 0.88 g of sodium molybdate, 1.40 g of sodium sulfide, and 0.6 g of glucose. After completely dissolving, adjust the pH value to about 6 with 2mol / L HCl. After stirring for 30 minutes, transfer the mixture to a 100mL stainless steel reaction kettle, place it in a vacuum drying oven at 160°C for 24 hours, and cool to room temperature; after centrifugation, the reaction product is washed repeatedly with deionized water and absolute ethanol , and finally dried at 60° C. for 12 h under vacuum to obtain a gray-black powder product, namely molybdenum disulfide flower-like nanorods. The obtained molybdenum disulfide flower-like nanorod has a diameter of 200-500 nm and a length of 1-2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com