Self-polymerized consolidated pressure-resistant high-permeability temperature-resistant sand control agent

A technology of sand control agent and high permeability, which is applied in the compound of group 4/14 elements of the periodic table, the composition of drilling holes, chemical instruments and methods, etc., and can solve the waterproof performance, high temperature resistance and compressive strength performance of sand control agent Insufficient, difficult to apply to shale gas wells with high temperature and high pressure, etc., to achieve the effect of enhanced hydrophobic barrier effect, excellent mechanical properties, and delayed infiltration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of modified epoxy resin is as follows:

[0028] Add 15.0g of epoxy resin E51, 5.0g of dimethoxybis(pentafluorophenyl)silane, 1.0g of dibutyltin dilaurate and 50.0g of toluene in sequence in the three-necked flask, and set the reaction temperature of the system at 85-90°C , reacted under stirring conditions for 8 hours, and after the reaction was completed, the temperature was lowered and toluene and unreacted dimethoxybis(pentafluorophenyl)silane were removed to obtain a modified epoxy resin.

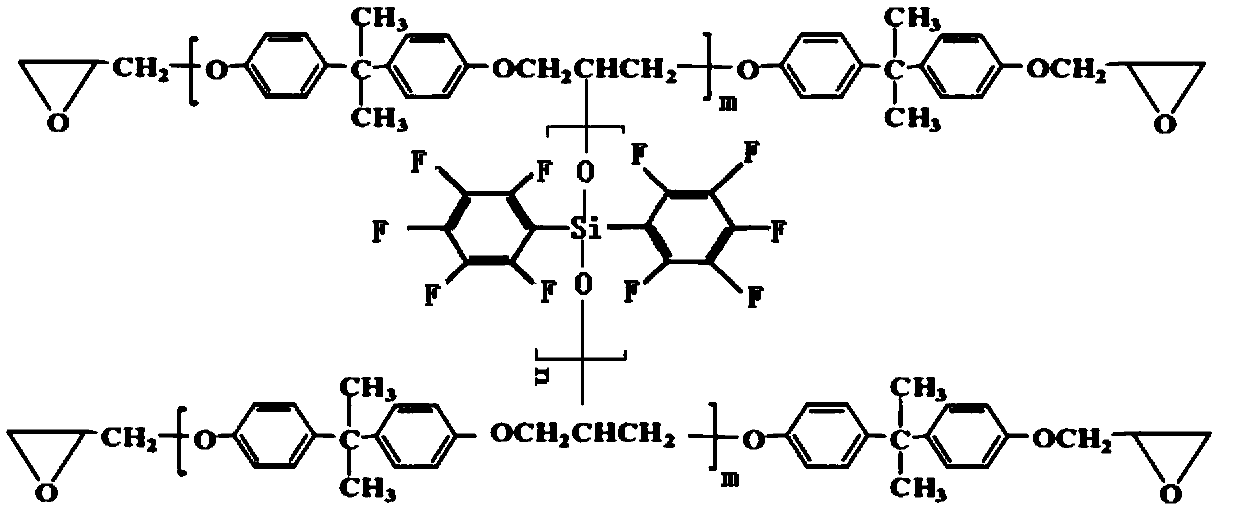

[0029] In the above preparation method, the hydroxyl group in the epoxy resin E51 and the alkoxy group in the dimethoxybis(pentafluorophenyl)silane condense to form a three-dimensional network structure organic polymer condensate, the chemical reaction equation as follows:

[0030]

[0031] In the formula, m takes an integer in the range of 1-4, and n=2.

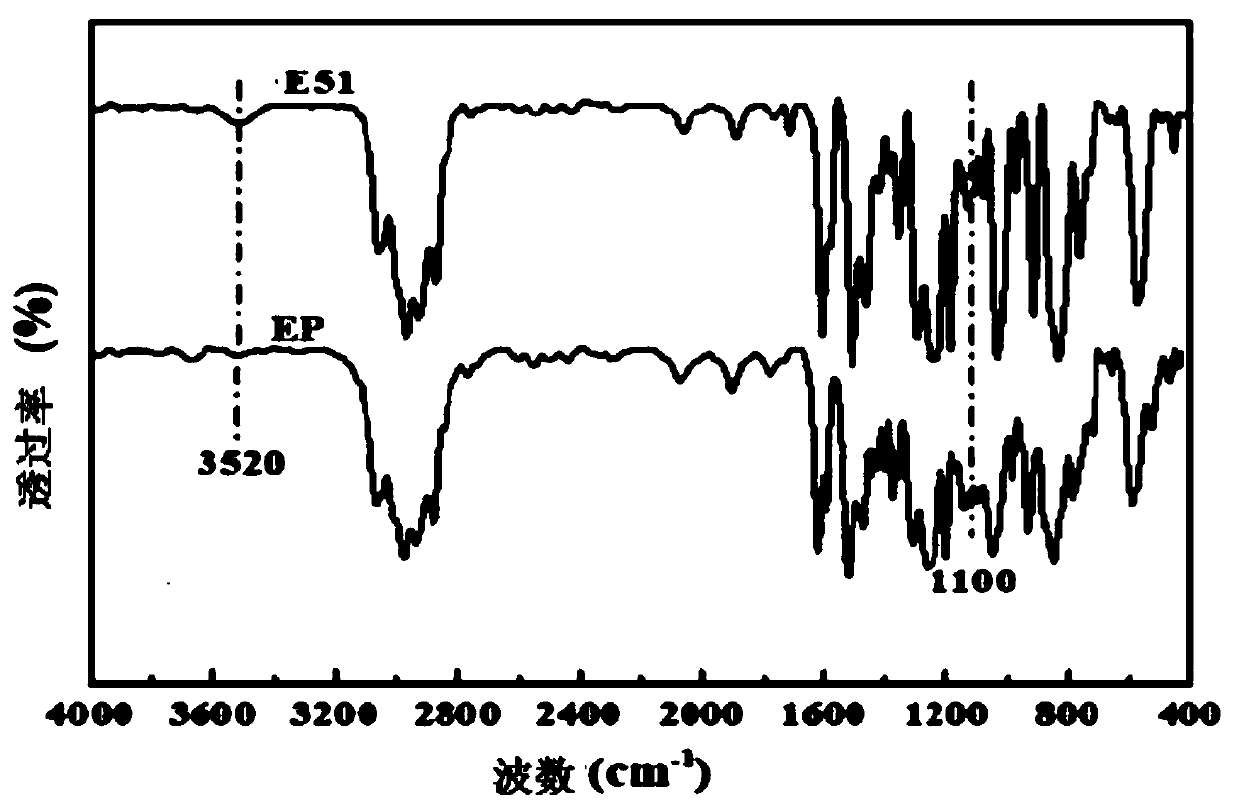

[0032] Carry out infrared spectrogram analysis to epoxy resin E51 before and after modification, ...

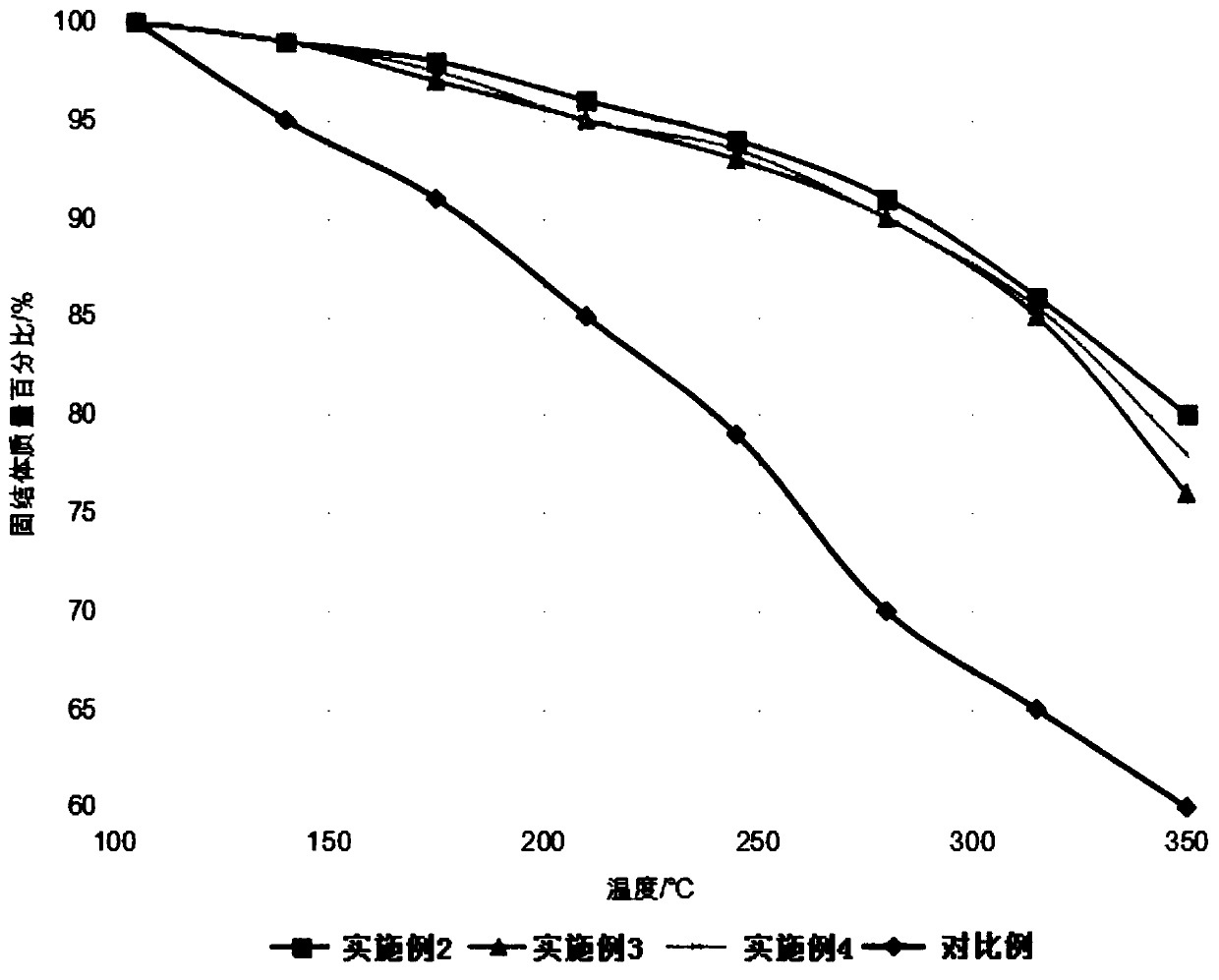

Embodiment 2

[0034] A kind of self-consolidation anti-compression high-permeability and temperature-resistant sand control agent, the specific composition is: the modified epoxy resin prepared in Example 1 40%, cyclohexanone 40%, γ-glycidyl ether oxypropyl trimethoxysilane 6%, polyoxyethylene sorbitan monooleate 8%, and m-phenylenediamine 6%, mix all the components evenly to obtain the sand control agent solidification liquid.

Embodiment 3

[0036] A kind of self-consolidation anti-compression high-permeability and temperature-resistant sand control agent, the specific composition is: the modified epoxy resin prepared in Example 1 40%, cyclohexanone 45%, γ-glycidyl ether oxypropyl trimethoxysilane 5%, polyoxyethylene sorbitan monooleate 5% and m-phenylenediamine 5%. Mix all the components evenly to obtain the sand control agent solidified liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com