Bio-based water-based anticorrosive conductive coating for bridge building protection and health monitoring and preparation method thereof

A technology for health monitoring and conductive coatings, applied in anti-corrosion coatings, conductive coatings, coatings, etc., can solve problems such as unfavorable environment and sustainable development, and achieve the effect of sensitive conductivity and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

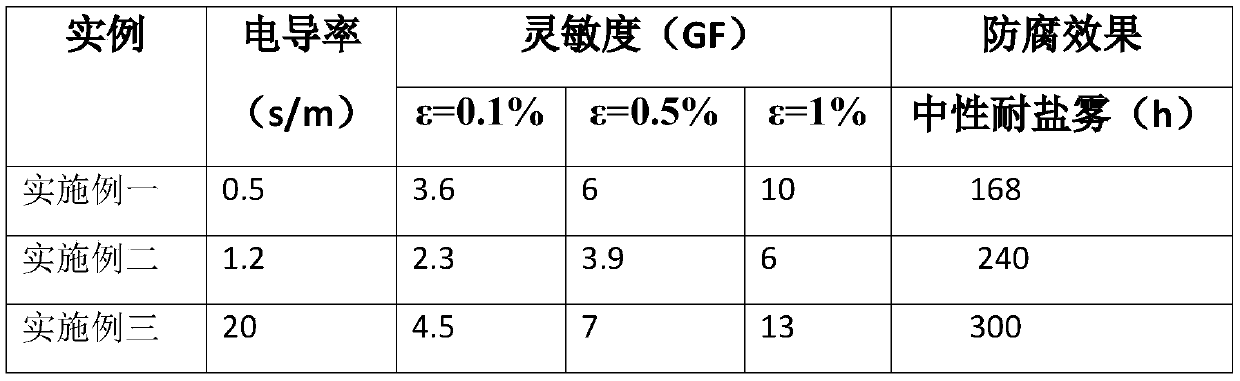

Examples

preparation example Construction

[0081] Specifically, a preparation method of a bio-based water-based anti-corrosion force-sensitive conductive coating for bridge building protection and health monitoring, the steps are as follows:

[0082] S1. Take 8 to 15 parts of conductive fillers to carry out surface treatment;

[0083] S2. Take 10-13 parts of bio-based resin, 0.3-0.6 parts of pH regulator, 3-5 parts of co-solvent, and 0.3-0.4 parts of drier and put them into the dispersion tank in order for dispersion treatment , the dispersion treatment time is 5 to 6 minutes, and the speed is 400 to 600 r / min to obtain solution I;

[0084] S3. Add 9 to 13 parts of deionized water into the solution I prepared in step S2, and perform dispersion treatment. The time of dispersion treatment is 5 to 6 minutes, and the speed is 400 to 600 r / min to obtain solution II;

[0085] S4. Take 0.2-0.3 parts of dispersant, 0.08-0.1 parts of defoamer, 0.1-0.3 parts of wetting agent, 15-18 parts of precipitated barium sulfate, 5-8 part...

Embodiment 1

[0099] The weight part of CM-3880 resin is: 20 parts;

[0100] PH regulator: 0.3 parts;

[0101] CM-001 drier: 0.3 parts;

[0102] 490 dispersant: 0.3 parts;

[0103] 901 defoamer: 0.1 part;

[0104] 348 wetting agent: 0.1 part;

[0105] Fumed silica A200: 0.5 parts;

[0106] Anti-flash rust additive Rb60: 0.4 parts;

[0107] Ethylene glycol butyl ether: 3 parts;

[0108] Precipitated barium sulfate: 15 parts;

[0110] Deionized water: 36.7 parts;

[0111] Thickener: 0.3 parts;

[0112] Anti-rust pigment: 3 parts

[0113] Nano carbon black or Mxene: 15 parts.

Embodiment 2

[0115] The weight part of CM-3880 resin is: 25 parts;

[0116] PH regulator: 0.6 parts;

[0117] CM-001 drier: 0.3 parts;

[0118] 490 dispersant: 0.3 parts;

[0119] 901 defoamer: 0.1 part;

[0120] 348 wetting agent: 0.1 part;

[0121] Fumed silica A200: 0.5 parts;

[0122] Anti-flash rust additive Rb60: 0.4 parts;

[0123] Ethylene glycol butyl ether: 5 parts;

[0124] Precipitated barium sulfate: 17 parts;

[0126] Deionized water: 31.4 parts;

[0127] Thickener: 0.3 parts;

[0128] Anti-rust pigment: 4 parts

[0129] Carbon nanotubes: 10 parts;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com