Continuous production method and system of heterogeneous system azo disperse dye

A disperse dye and heterogeneous technology, applied in the direction of azo dyes, monoazo dyes, chemical instruments and methods, etc., can solve problems such as difficult, difficult to ensure uniformity, and azo disperse dyes have not yet appeared, and achieve advanced The effect of reducing the difficulty of materials, reducing the coupling reaction time, achieving stability and simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

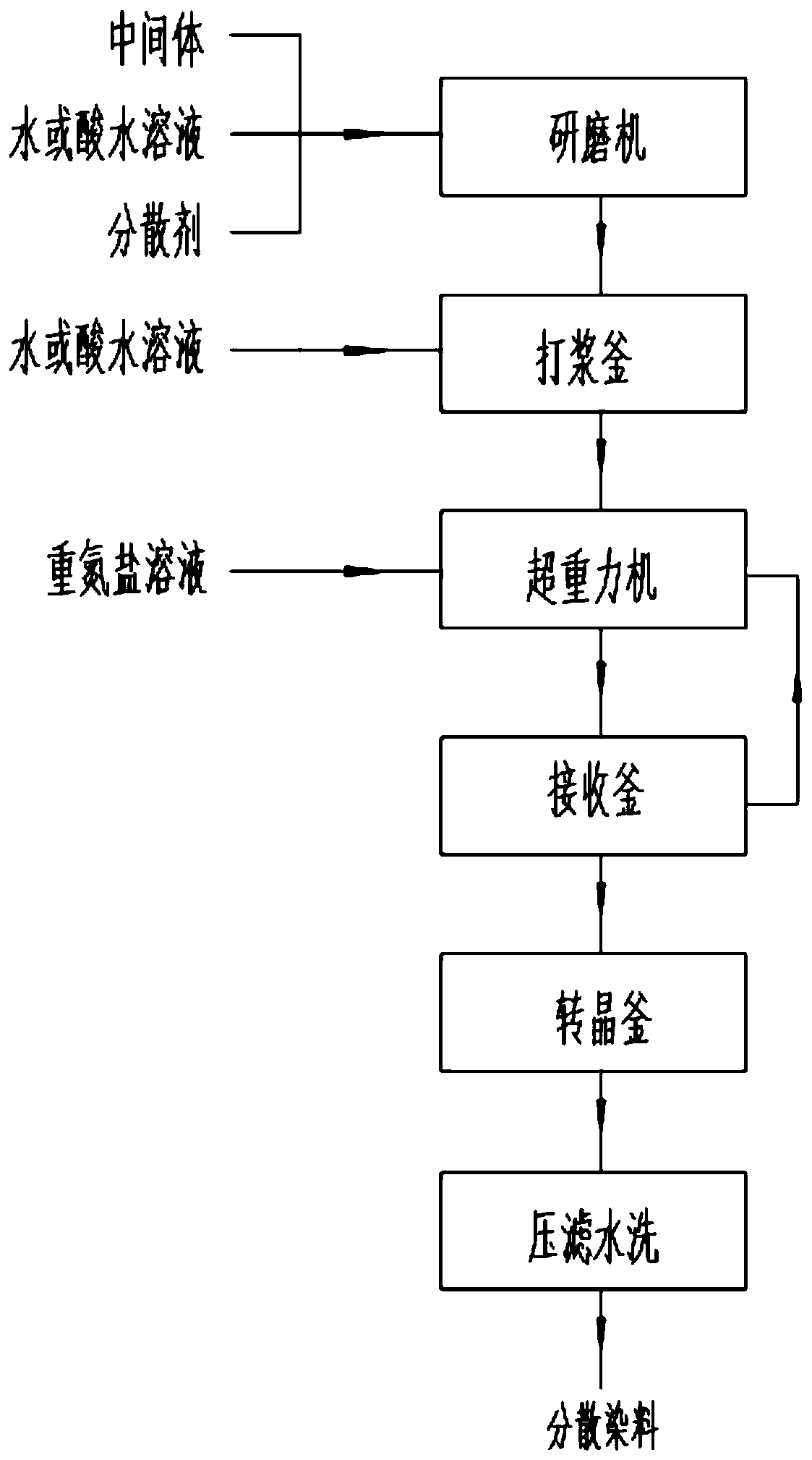

Image

Examples

Embodiment 1

[0058] (1) Coupling component beating

[0059] Weigh 20kg of N-cyanoethyl-N-benzylaniline, add 400kg of water, add 0.04kg of dispersant MF and stir to premix, add the obtained premix to a grinder for grinding, and adjust the grinding particle size to 4-8 μm by a grinding disc. Add the ground material into the beating kettle, open the beating kettle and stir, add 50 kg of water and 30 kg of sulfuric acid, turn on the temperature control system, and control the temperature of the beating liquid to about 20-30 ° C to obtain milky white N-cyanoethyl-N-benzylaniline suspension.

[0060] (2) Coupling reaction

[0061] Prepare 53.55kg of p-nitroaniline diazonium salt solution by diazotization equipment, keep the temperature for 25~

[0062] 30 ℃, keep stirring; again, the diazonium salt solution is pumped into the supergravity rotating bed through the metering pump to adjust the flow rate to be 350g / min, and the coupling component slurry prepared in step (1) is adjusted to the flow...

Embodiment 2

[0064] (1) Coupling component beating

[0065] Using the beating method of Example 1, 2-methoxy-5-acetamido-(N,N-diallyl)aniline, water and dispersant MF were ground and pulped to obtain milky white 2-methoxy- 5-Acetylamino-(N,N-diallyl)aniline suspension.

[0066] (2) Coupling reaction

[0067] Using the coupling reaction method of Example 1, 2,4-dinitro-6-bromoaniline diazonium salt solution and 2-methoxy-5-acetamido-(N,N-diallyl)aniline were added to The slurry was pumped into a supergravity rotating bed, and reacted to obtain a coupled product, which was heated up, crystallized, filtered by pressure, and washed with water to obtain Disperse Blue 291 dye with a yield of 97.7% and a sample purity of 94.8%.

Embodiment 3

[0069] (1) Coupling component beating

[0070] Using the beating method of Example 1, grinding and beating 3-acetamido-(N,N-diethyl)aniline, water and dispersant MF to obtain milky white 3-acetamido-(N,N-diethyl) ) aniline suspension.

[0071] (2) Coupling reaction

[0072] Using the coupling reaction method of Example 1, the 2,4-dinitro-6-bromoaniline diazonium salt solution and 3-acetamido-(N,N-diethyl)aniline slurries were pumped into the hypergravity rotating bed , carry out the reaction to obtain the coupling product, carry out heating, crystallization, pressure filtration, and water washing to obtain the disperse violet 93 dye, the yield is 95.4%, and the sample purity is 93.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com