Polymer/inorganic nanoparticle composite material and preparation method thereof

A technology of inorganic nanoparticles and composite materials, applied in the field of polymer/inorganic nanocomposite materials and their preparation, to achieve the effects of cost saving, simple and fast reaction, and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

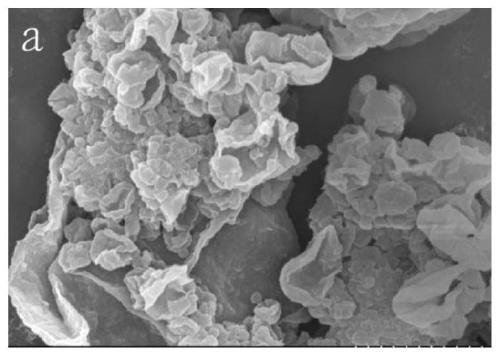

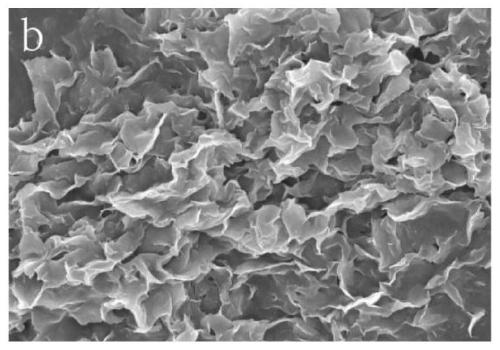

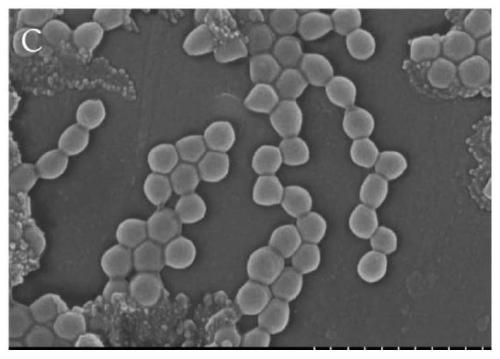

Image

Examples

Embodiment 1

[0034] A preparation method of a polymer / inorganic nanoparticle composite material, comprising the steps of:

[0035] (1) Weigh 0.1g of inorganic nanoparticles, 0.063g of tris(hydroxymethyl)aminomethane hydrochloride (concentration: 10mM) and 0.005g of dopamine hydrochloride (concentration: 0.5mg / ml), and add them to 10ml of deionized water one by one , mix evenly, use hydrochloric acid and sodium hydroxide solution to adjust the pH of the mixed solution to 8.5, and react for 1 hour under stirring to obtain an aqueous solution of inorganic nanoparticles modified by polydopamine;

[0036] (2) Weigh 0.5g of the initiator ammonium persulfate and dissolve it in 4ml of deionized water, mix well to ensure that the concentration of the initiator ammonium persulfate in the entire reaction system is 0.012g / ml;

[0037] (3) Into a three-necked flask with a volume of 250ml, add the polydopamine-modified inorganic nanoparticle aqueous solution, 5g monomer, and deionized water in sequence in...

Embodiment 2

[0041] A preparation method of a polymer / nano silicon dioxide composite material, comprising the steps of:

[0042] (1) Measure 2ml of silica sol Ludox TM40 with a mass percentage concentration of 40 wt% (silica solid content is 1.04g), 0.063g tris(hydroxymethyl)aminomethane hydrochloride (concentration is 10mM) and 0.005g Add dopamine hydrochloride (concentration: 0.5 mg / ml) into 10 ml of deionized water one by one, mix well, use hydrochloric acid and sodium hydroxide solution to adjust the pH of the mixture to 8.5, and react for 1 hour under stirring to obtain polydopamine-modified Nano silicon dioxide aqueous solution;

[0043] (2) Weigh 0.5g of the initiator ammonium persulfate and dissolve it in 4ml of deionized water, mix well to ensure that the concentration of the initiator ammonium persulfate in the entire reaction system is 0.012g / ml;

[0044] (3) Add the polydopamine-modified nano-silica solution described in step (1), 5g of monomer, and deionized water (to ensure ...

Embodiment 3

[0050] A kind of preparation method of polystyrene / nanometer silicon dioxide composite material, comprises the steps:

[0051] (1) Measure 2ml of silica sol Ludox TM40 with a mass percentage concentration of 40 wt% (silica solid content is 1.04g), 0.063g tris(hydroxymethyl)aminomethane hydrochloride (concentration is 10mM) and 0.005g Add dopamine hydrochloride (concentration: 0.5 mg / ml) into 10 ml of deionized water one by one, mix well, use hydrochloric acid and sodium hydroxide solution to adjust the pH of the mixture to 8.5, and react for 1 hour under stirring to obtain polydopamine-modified Nano silicon dioxide aqueous solution;

[0052] (2) Weigh 0.5g of initiator and dissolve it in 4ml of deionized water, mix well to ensure that the initiator concentration of the entire reaction system is 0.012g / ml;

[0053] (3) Add the polydopamine-modified nano-silica solution, 5g of styrene, and deionized water (to ensure that the whole system is 45ml of deionized water) in sequence ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com