Hydrate of micheliolide dimethylamine fumarate, preparation method and application thereof

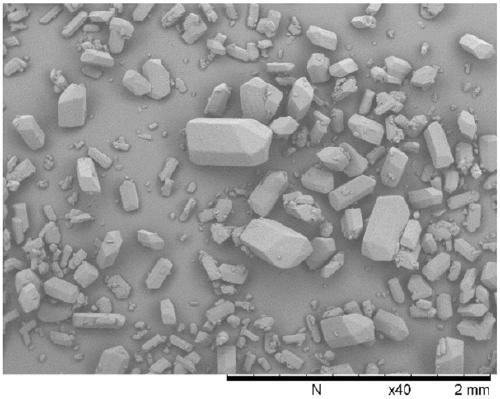

A technology of dimethylamine fumarate and hydrate, which is applied in the field of microlactone dimethylamine fumarate hydrate, which can solve the problems of small particle size, poor stability and poor fluidity of crystal form A , to achieve the effect of solving small bulk density, increasing particle size and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Hydrate of Milactone Dimethylamine Fumarate

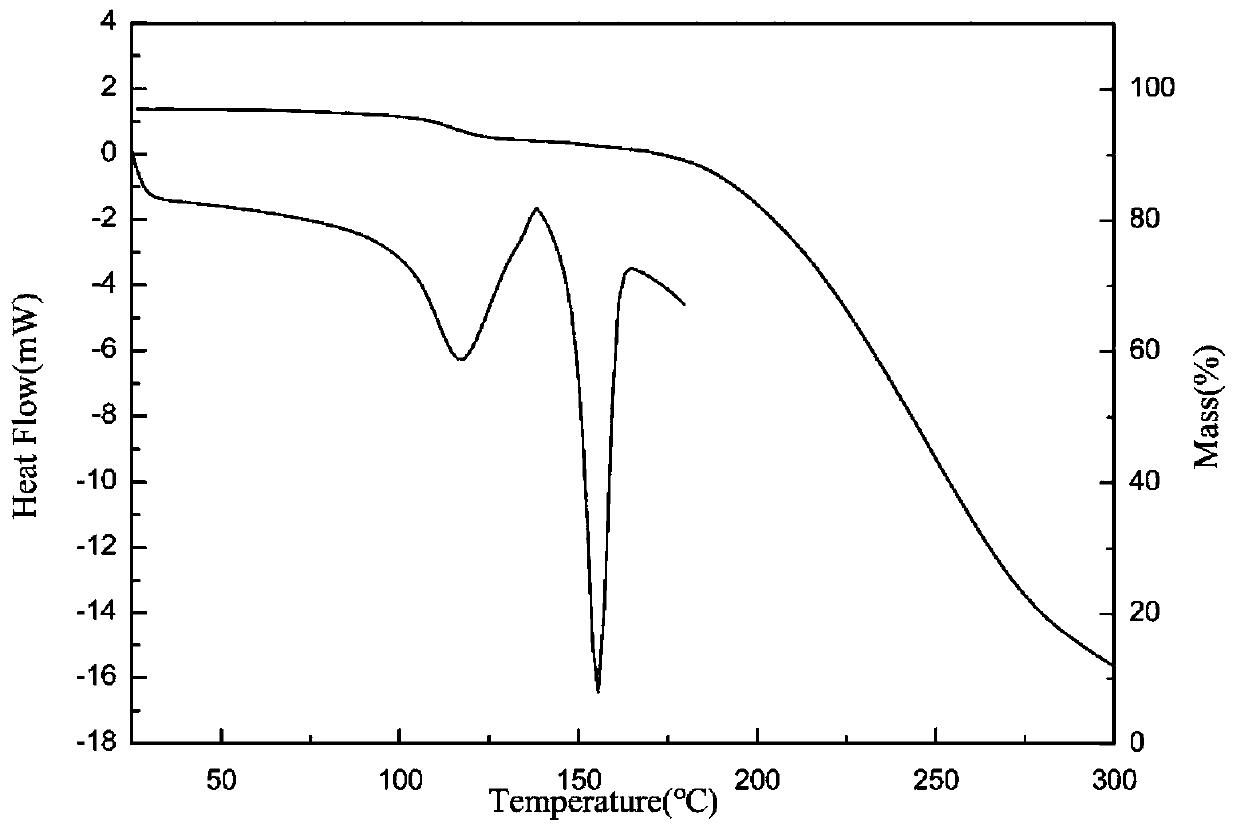

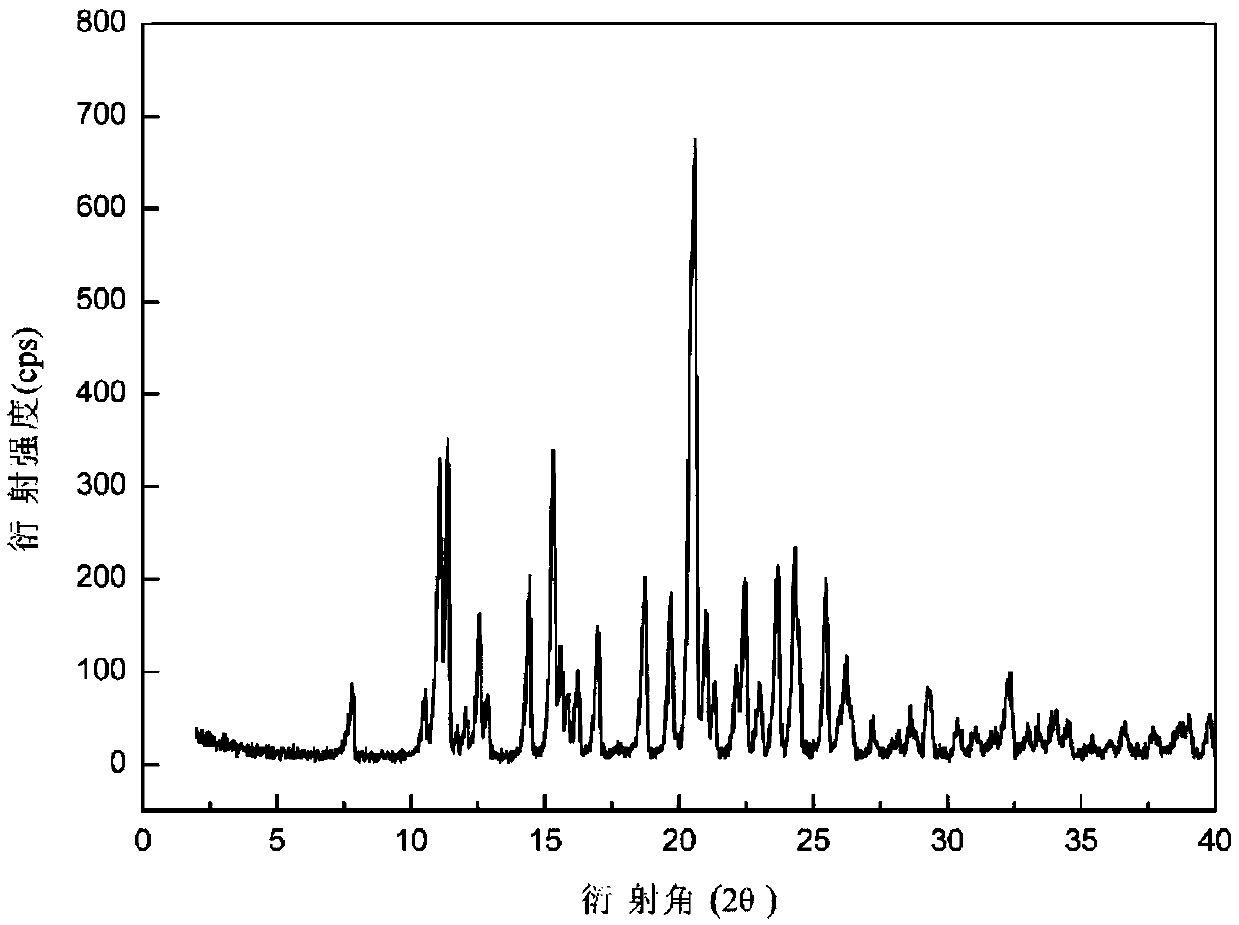

[0043] Under the action of stirring, 0.293g of dimethylamine michelolactone and 0.116g of fumaric acid were added to the mixed solvent system of solvent S1 and solvent S2 whose temperature was constant at 30°C. The quality of solvent S1 was the same as that of solvent S2. Among them, solvent S1 is composed of 1.598g of acetone solvent and 0.16g of water, and solvent S2 is composed of 0.879g of ethyl acetate and 0.879g of diethyl ether. After reacting for 5 hours, filter and dry at 25°C for 6 hours under normal pressure to obtain michelactone dimethylamine Fumarate D crystal product. Thermogravimetric analysis / differential scanning calorimetry of the product and additional figure 1 Consistently, thermogravimetric analysis showed a 4.22% weight loss before decomposition, and differential scanning calorimetry showed a dehydration endothermic peak at 75°C and a characteristic melting peak at 148°C. The X-ray po...

Embodiment 2

[0045] Preparation of Hydrate of Milactone Dimethylamine Fumarate

[0046] Under the action of stirring, 1.758g of dimethylamine michelolactone and 0.58g of fumaric acid were added to the mixed solvent system of solvent S1 and solvent S2 whose temperature was constant at 50°C. The quality of solvent S2 was 2 times that of solvent S1. times, the solvent S1 is composed of 12.306g tetrahydrofuran solvent and 1.758g water, and the solvent S2 is composed of 21.096g isopropyl acetate and 7.032g methyl tert-butyl ether. After reacting for 8 hours, filter and dry under normal pressure at 30°C for 10 hours. A crystal form D product of mimilactone dimethylamine fumarate was obtained. Thermogravimetric analysis / differential scanning calorimetry of the product and additional figure 1 Consistently, thermogravimetric analysis showed a 4.20% weight loss before decomposition, and differential scanning calorimetry showed a dehydration endothermic peak at 78°C and a characteristic melting pea...

Embodiment 3

[0048] Preparation of Hydrate of Milactone Dimethylamine Fumarate

[0049] Under the action of stirring, 4.688g of dimethylamine michelolactone and 1.16g of fumaric acid were added to the mixed solvent system of solvent S1 and solvent S2 whose temperature was constant at 70°C. The quality of solvent S2 was 3 times that of solvent S1. times, the solvent S1 is composed of 39g 1,4-dioxane solvent and 7.88g water, and the solvent S2 is composed of 93.76g methyl acetate and 46.88g methyl ethyl ether. After reacting for 10h, filter and store under normal pressure at 45°C After drying for 8 hours, the crystal form D product of mimilactone dimethylamine fumarate was obtained. Thermogravimetric analysis / differential scanning calorimetry of the product and additional figure 1 Consistently, thermogravimetric analysis showed a 3.97% weight loss before decomposition, and differential scanning calorimetry showed a dehydration endothermic peak at 75°C and a characteristic melting peak at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com