Double-shell asymmetric semiconductor material and super-assembly method thereof

An assembly method, asymmetric technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, other chemical processes, etc., can solve problems such as speed needs to be improved, limited motor application range, etc., to achieve transmission and separation. Efficiency improvement, photoelectric conversion efficiency improvement, wide pore size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a double-shell asymmetric semiconductor material and its super-assembly method.

[0029] The superassembly method of double-shell asymmetric semiconductor materials includes the following steps:

[0030] Step 1: Asymmetric bottle-shaped open carbon polymer frameworks (VPFs for short) were prepared by microemulsion template method in a hydrothermal environment.

[0031] Its specific process includes:

[0032] In step S1-1, the template agent is first dissolved in deionized water, and stirred until it becomes a clear solution, that is, a uniform microemulsion system is formed. Among them, the templating agent is composed of triblock copolymer PEO 20 -PPO 70 -PEO 20 (referred to as P123) and sodium salt self-assembled, the sodium salt is any one of sodium oleate (SO), sodium stearate, sodium laurate, and the molar ratio of P123 and sodium salt is 1: (2- 32), the molar mass ratio of template agent to water is 0.1275mmol: (40mL-100mL). In this ...

Embodiment 2

[0046] This example is the double-shell asymmetric TiO prepared in Example 1 2 @TiO 2 Semiconductor materials and hollow TiO 2 The nanospheres were compared in terms of structure, ultraviolet absorption, photocurrent performance, and motion performance in water.

[0047] 1. Structure

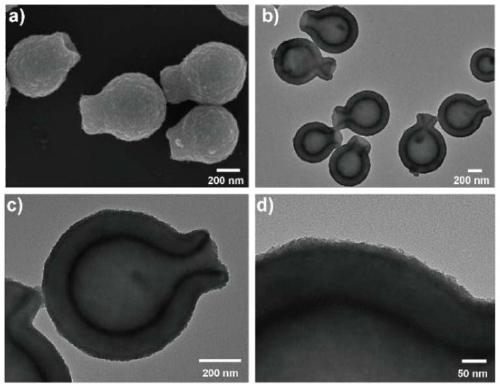

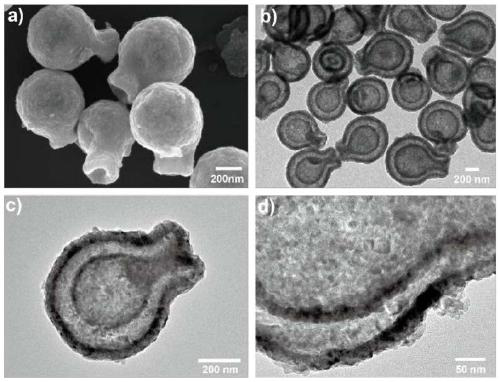

[0048] Figure 4 : It is hollow TiO in embodiment 2 of the present invention 2 Electron micrographs of nanospheres, wherein (a-b) is transmission electron micrographs; Figure 5 : It is double-shell asymmetric TiO in embodiment 2 of the present invention 2 @TiO 2 XRD diffraction patterns of semiconductor materials and hollow TiO2 nanospheres.

[0049] From Figure 4 It can be seen that the prepared hollow TiO 2 The size of the nanosphere is uniform, and it is a hollow and closed single-shell structure. The thickness of the shell layer is about 40nm, and the diameter is about 500nm. From Figure 5 As can be seen in the hollow TiO 2 Nanospheres and double-shell asymmetric TiO 2 @TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com