Method for removing impurities and whitening phosphogypsum

A technology of phosphogypsum and flotation agent, which is applied in the field of phosphorus chemical industry, can solve the problems that it is difficult to remove heavy impurities with large particle size, it is difficult to further improve the whiteness and purity, and it is difficult to deal with organic impurities and quartz impurities, so as to achieve wide industrial application Prospects, reduction and harmlessness, and the effect of facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

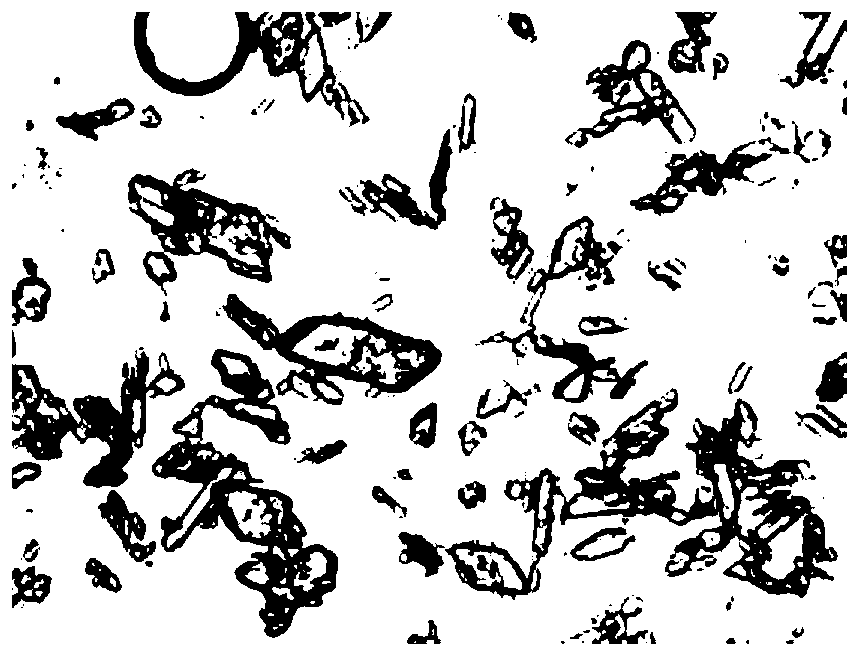

Image

Examples

Embodiment 1

[0059] The dry base chemical composition of phosphogypsum in an enterprise is shown in Table 1 below.

[0060] Table 1 Dry basis chemical composition of phosphogypsum

[0061] Element SO 3

CaO SiO 2

P 2 o 5

al 2 o 3

Fe 2 o 3

K 2 o

TiO 2

MgO SrO Na 2 o

V 2 o 5

Cl content% 56.40 37.15 4.63 0.79 0.36 0.23 0.16 0.09 0.08 0.046 0.045 0.024 -

[0062] 1. Put phosphogypsum and 35% sulfuric acid into the reaction kettle with a mass ratio of 1:1.5, and stir;

[0063] 2. Heat to 85 degrees Celsius and keep for 1.5 hours;

[0064] 3. Add collector, the ratio is 1:2 based on phosphogypsum;

[0065] 4. After stirring evenly, let stand to separate the lower slurry layer;

[0066] 5. The upper layer is filtered to remove impurities and then recycled;

[0067] 6. The lower slurry is filtered and washed until neutral; the acidic filtrate is recycled;

[0068] 7. After the filter cake is wa...

Embodiment 2

[0074] The chemical composition of phosphogypsum dry basis impurities calculated by oxides in another enterprise is shown in Table 3 below.

[0075] Table 3 The chemical composition of phosphogypsum dry base impurities calculated by oxides

[0076] Element SiO 2

[0077] 1. Put phosphogypsum and 30% sulfuric acid into the reaction kettle with a mass ratio of 1:3, and stir;

[0078] 2. Heat to 90 degrees Celsius and keep for 1 hour;

[0079] 3. Add collector, the ratio is 1:3 based on phosphogypsum;

[0080]4. After stirring evenly, let stand to separate the lower slurry layer;

[0081] 5. The upper layer is filtered to remove impurities and then recycled;

[0082] 6. The lower layer slurry is added with extractant to continue the extraction, and the ratio is 1:5 in terms of phosphogypsum;

[0083] 7. The upper layer is filtered to remove impurities and then recycled;

[0084] 8. The lower slurry is filtered and washed until neutral; the acidic filtrate is re...

Embodiment 3

[0091] The fresh phosphogypsum from a phosphoric acid plant has a blue light whiteness of 25-30, and the scheme involved in this process is used for impurity removal and purification treatment:

[0092] 1. Phosphogypsum is subjected to pre-screening and particle size classification;

[0093] 2. Carry out water washing and flotation roughing for the products with qualified particle size (the dosage of flotation agent is 8-40kg / t dry ore);

[0094] 3. Flotation coarse concentrate is heated and atmospheric pressure acid leaching, and a small amount of collection aid is added to separate and enrich impurities in time;

[0095] 4. The slurry obtained by acid leaching is adjusted and then flotation and selected (the amount of flotation agent is 1-14kg / t dry ore);

[0096] 5. The impurity product obtained in each step is carried out by flotation and sweeping, and the calcium sulfate product mixed in the impurity is reclaimed;

[0097] 6. The calcium sulfate concentrate product is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com