Grinding device for low-temperature ferrite ball-mill iron casting machining

A technology for ferrite and iron parts, which is applied in the direction of grinding drive device, grinding/polishing safety device, grinding workpiece support, etc. It can solve the problems of irregular chamfering, low grinding precision, and low grinding efficiency, and achieve Effects of preventing debris residue, facilitating rotation, and improving grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

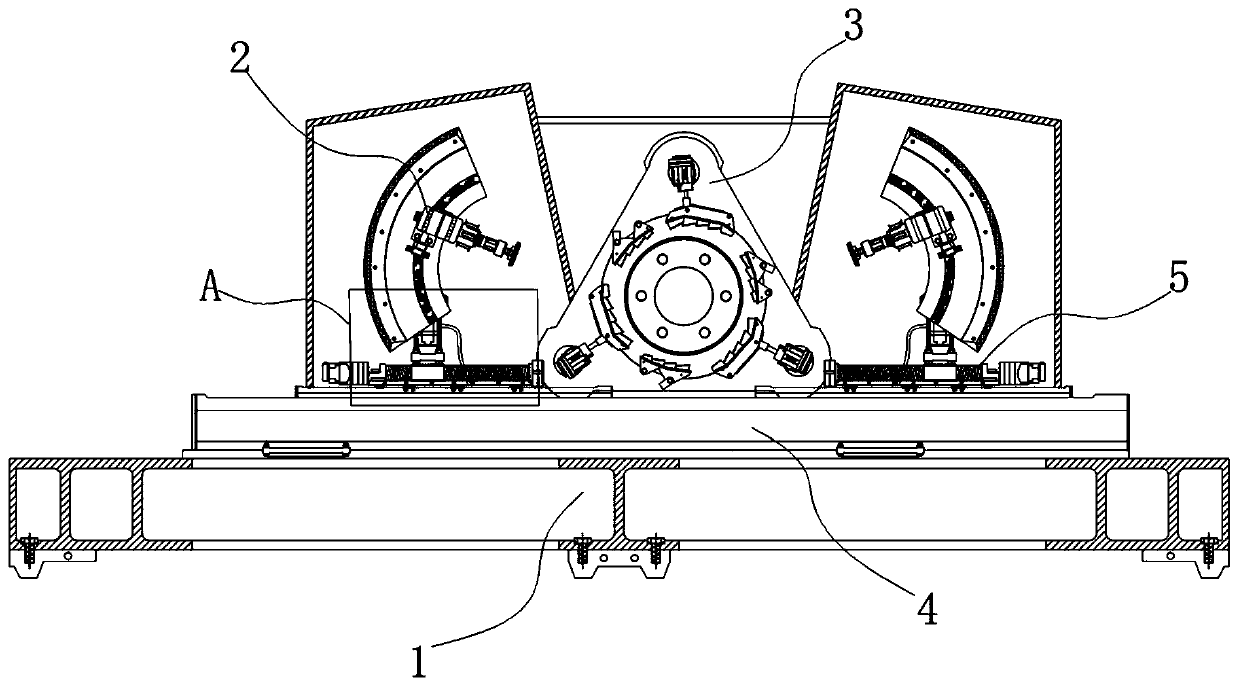

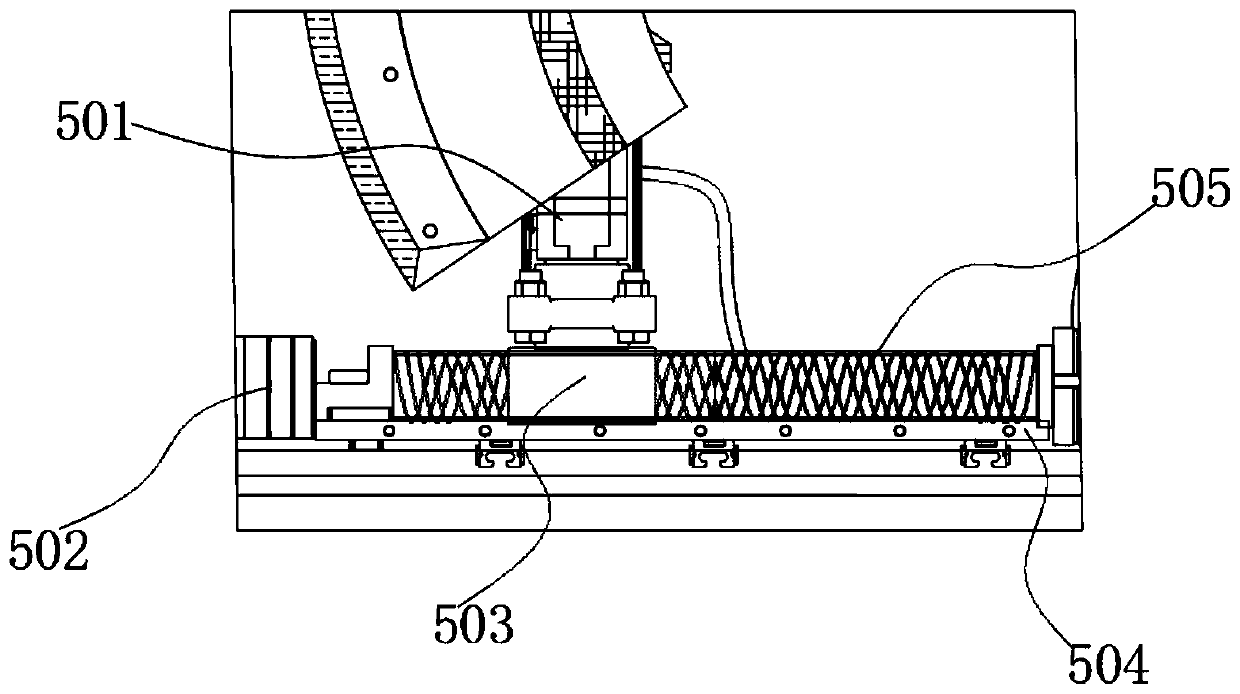

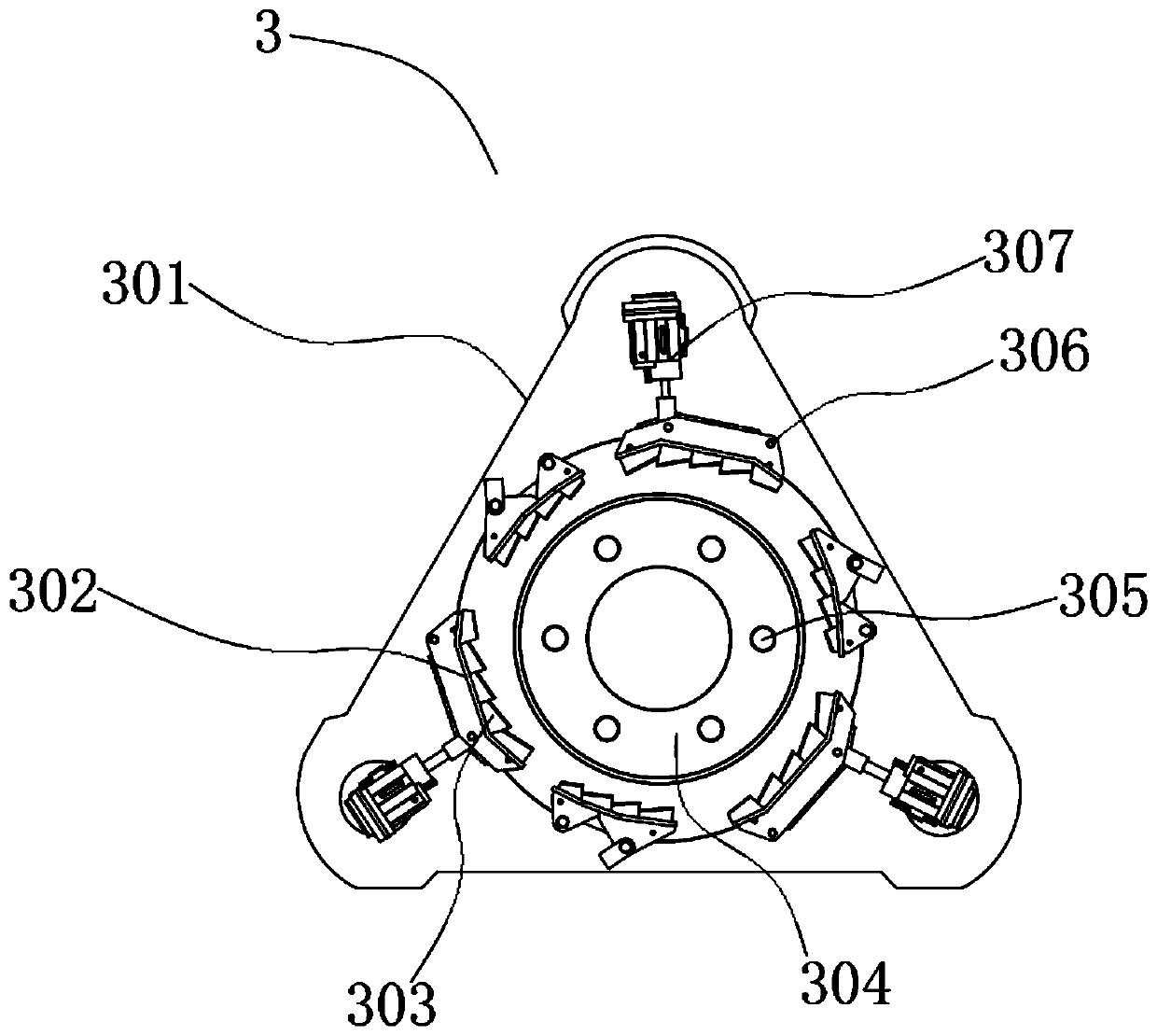

[0022] refer to figure 1 , the present invention provides a technical solution: a grinding device for processing low-temperature ferrite ball mill iron pieces, which includes a support base 1, a grinding table 4, a transmission lifting assembly 5, a clamping assembly 3, and a grinding assembly 2, the The upper end surface of the support base 1 is fixed with a grinding table 4, and a triangular fixing frame 301 is installed at the middle position of the upper end surface of the grinding table 4, and a clamping assembly 3 is arranged in the triangular fixing frame 301, and the triangular fixing frame Both sides of 301 are symmetrically provided with two sets of transmission lifting components 5, the transmission lifting components 5 are fixedly arranged on the upper surface of the grinding table 4, and the grinding components 2 are installed on the transmission lifting components 5, so as to control the grinding components 2 The working distance from the iron piece to be polishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com