Welding method of tp347 high pressure thick wall stainless steel pipe

A welding method and stainless steel technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to guarantee processing accuracy and time-consuming, and achieve the effect of reducing labor input, good cleaning efficiency, and improving welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

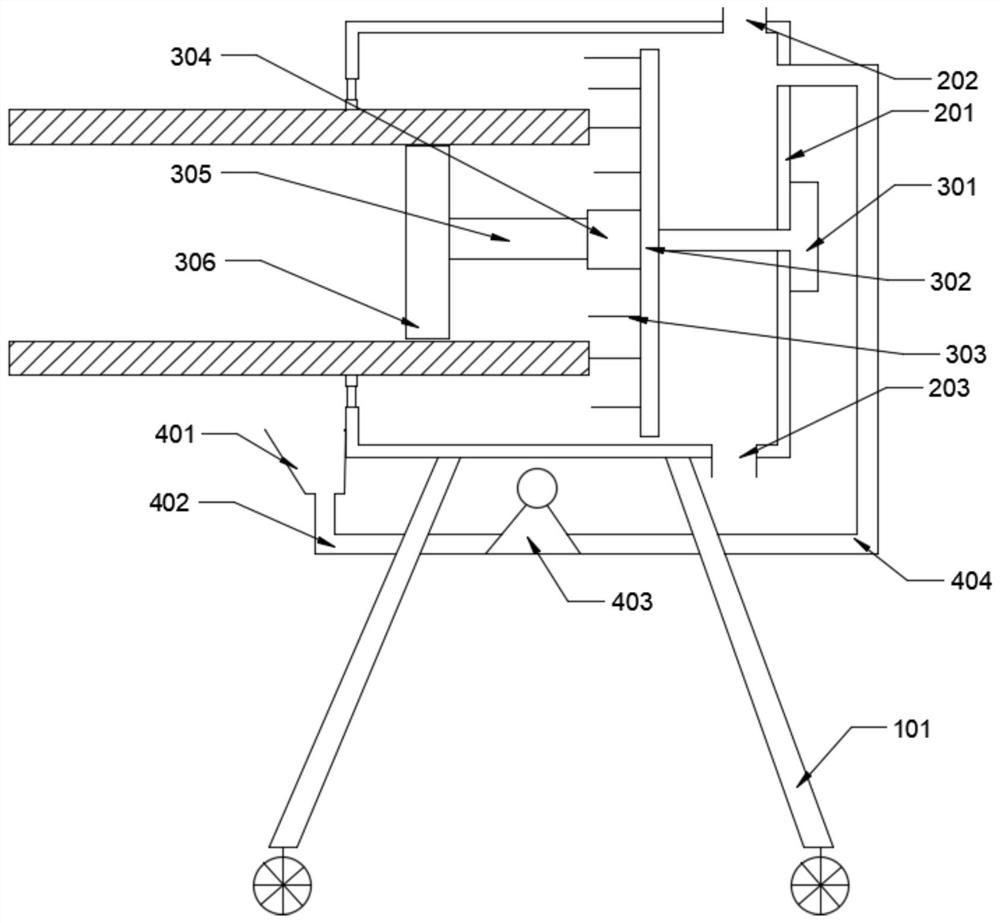

[0032] Such as Figure 1-3 As shown, the welding method of TP347 high-pressure thick-walled stainless steel pipeline includes the following steps:

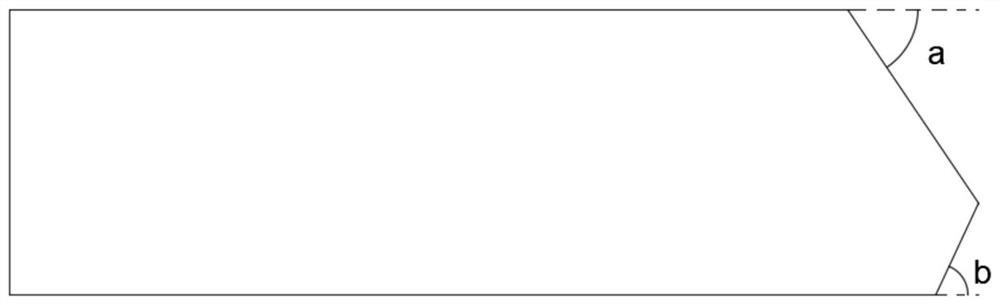

[0033] Step 1. Pipe groove processing: Use groove machine to process the groove of the two pipes to be welded, and the groove is double V-shaped;

[0034] Step 2. Cleaning the groove of the pipeline: firstly, the groove is polished and cleaned, and then the nozzle of the pipeline with the groove is placed in a sodium hydroxide solution with a mass fraction of 5% for 2 hours using a soaking device. include:

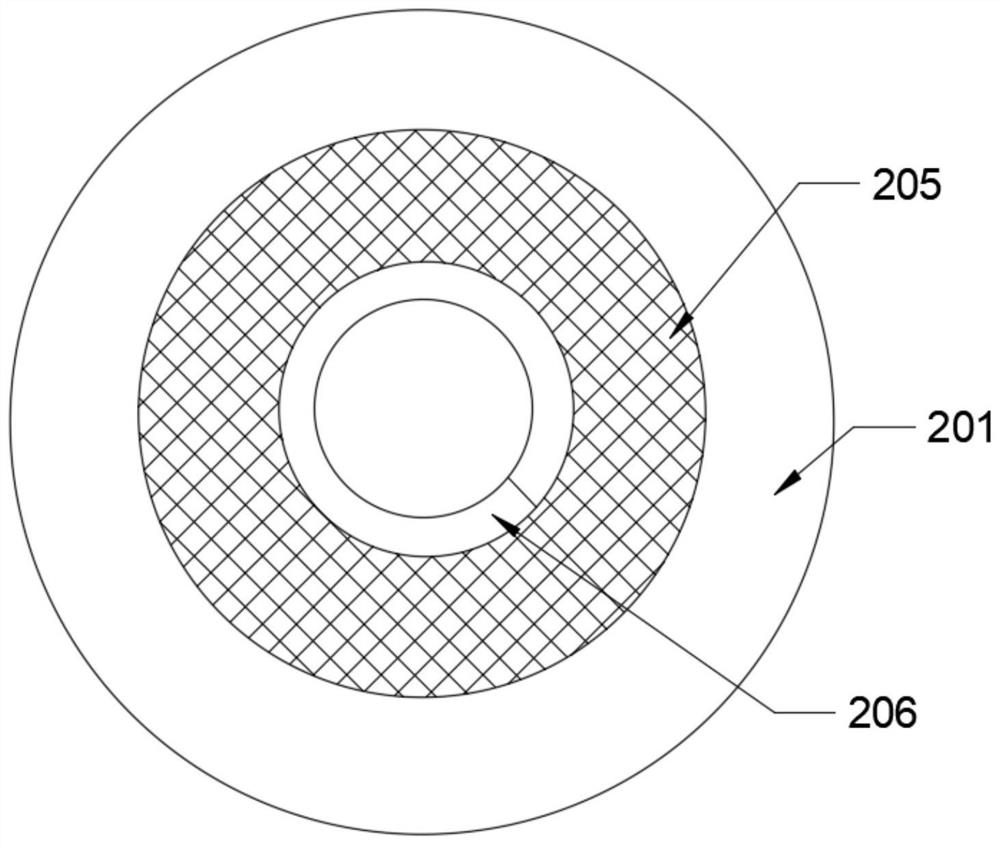

[0035] Support 101, which can be raised and lowered (helping to make the sprint device suitable for pipes of different diameters), the bottom end of the support 101 is provided with moving wheels, so as to facilitate the movement of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com