Silver-nickel or silver-iron electric contact material and preparation method thereof

An electrical contact material, silver-iron technology, applied in contacts, circuits, electrical switches, etc., can solve the problems of high manufacturing cost, pollution, and high comprehensive cost, improve consistency and reliability, improve distribution uniformity, eliminate uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] a) 18kg silver is melted in the graphite crucible of intermediate frequency smelting furnace, forms silver melt;

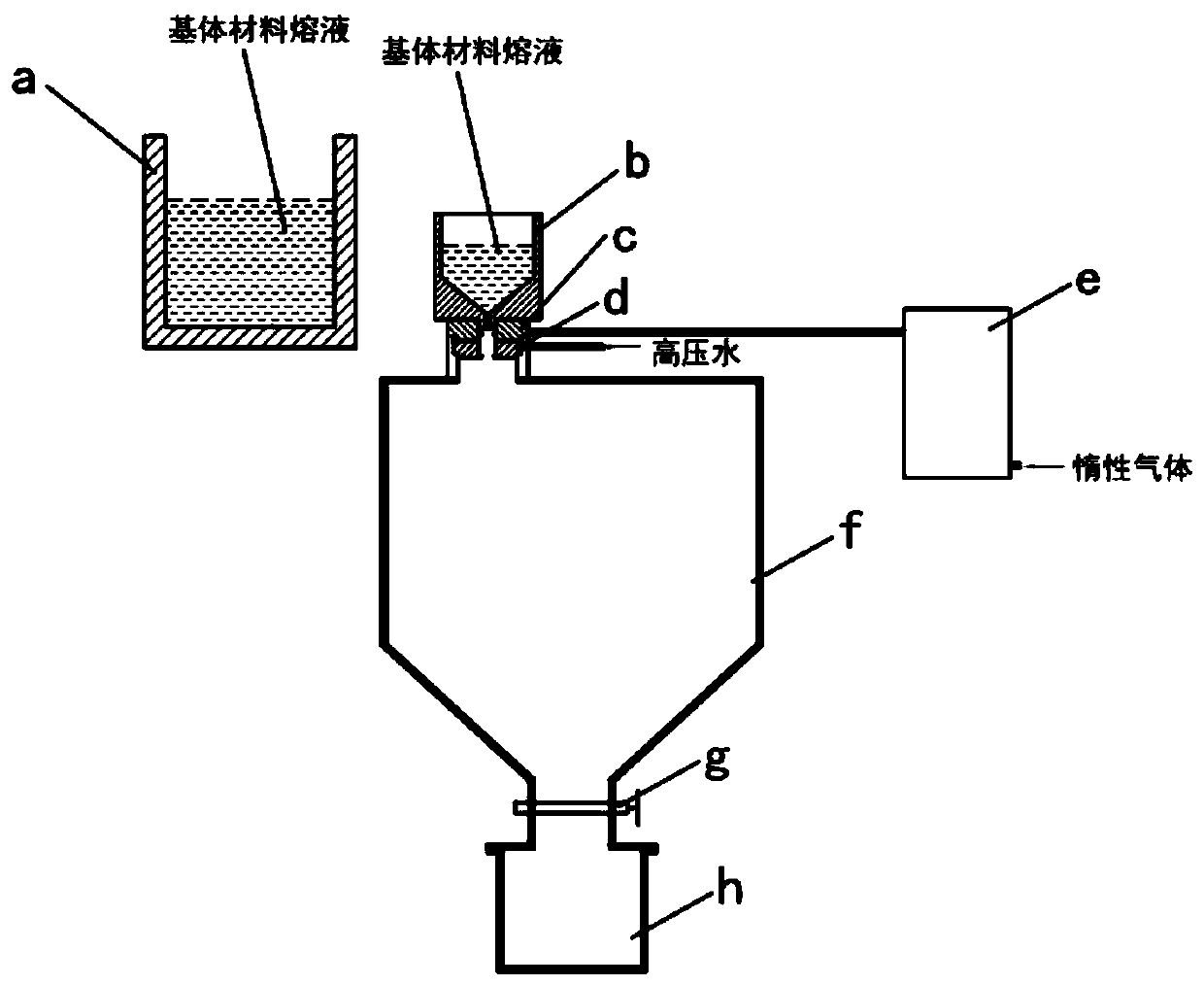

[0037] b) 1.8 kg of carbonyl Ni powder with an average particle size of 0.1 μm and 0.2 kg of W powder with an average particle size of 2 μm are evenly mixed, loaded into the powder spraying device, and connected to the upper spray plate of the high-pressure water atomization equipment; The pressure of pure nitrogen is 0.2MPa, and the flow rate of inert gas is 200L / min;

[0038] c) The lower spray plate of the high-pressure water atomization equipment is connected to high-pressure water, the water pressure is set to 20MPa, and the atomization equipment is turned on;

[0039] d) The molten silver is poured into the collection bucket from the center of the spray plate of the high-pressure water atomization equipment through the heat preservation crucible, and the powder spraying device is turned on. With high-purity nitrogen as the carrier, the mixed powder of...

Embodiment 2

[0043] a) 20kg silver is melted in the graphite crucible of intermediate frequency smelting furnace, forms silver melt;

[0044] b) 4.5 kg of carbonyl Ni powder with an average particle size of 5 μm, 0.2 kg of WO with an average particle size of 1 μm 3 Powder, 0.3kg of Re powder with an average particle size of 10μm are mixed evenly, loaded into the powder spraying device, and connected to the upper spray plate of the high-pressure water atomization equipment; the pressure of high-purity argon in the powder spraying equipment is set to 1.0MPa, and the flow rate of the inert gas is 1000L / min;

[0045] c) The lower spray plate of the high-pressure water atomization equipment is connected to high-pressure water, the water pressure is set to 200MPa, and the atomization equipment is turned on;

[0046] d) The molten silver is poured into the collection bucket from the center of the spray plate of the high-pressure water atomization equipment through the heat preservation crucible,...

Embodiment 3

[0050] a) 8.8kg silver is melted in the graphite crucible of intermediate frequency smelting furnace to form silver melt;

[0051] b) 1 kg of carbonyl Fe powder with an average particle size of 20 μm, 0.1 kg of WC powder with an average particle size of 0.1 μm, 0.05 kg of VC powder with an average particle size of 3.5 μm, and 0.05 kg of MoC powder with an average particle size of 5 μm are mixed uniformly, and packed into a powder spraying device, And connected to the upper spray plate of the high-pressure water atomization equipment; set the high-purity argon pressure in the powder spray equipment to 0.5MPa, and the inert gas flow rate to 600L / min;

[0052] c) The lower spray plate of the high-pressure water atomization equipment is connected to high-pressure water, the water pressure is set to 100MPa, and the atomization equipment is turned on;

[0053] d) The silver melt is poured into the collection bucket from the center of the spray plate of the high-pressure water atomiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com