Long nozzle structure for free injecting flow of tundish and argon blowing smelting method

A smelting method and tundish technology, applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of high energy consumption and maintenance costs, and achieve easy maintenance of equipment, saving energy consumption of argon filling, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

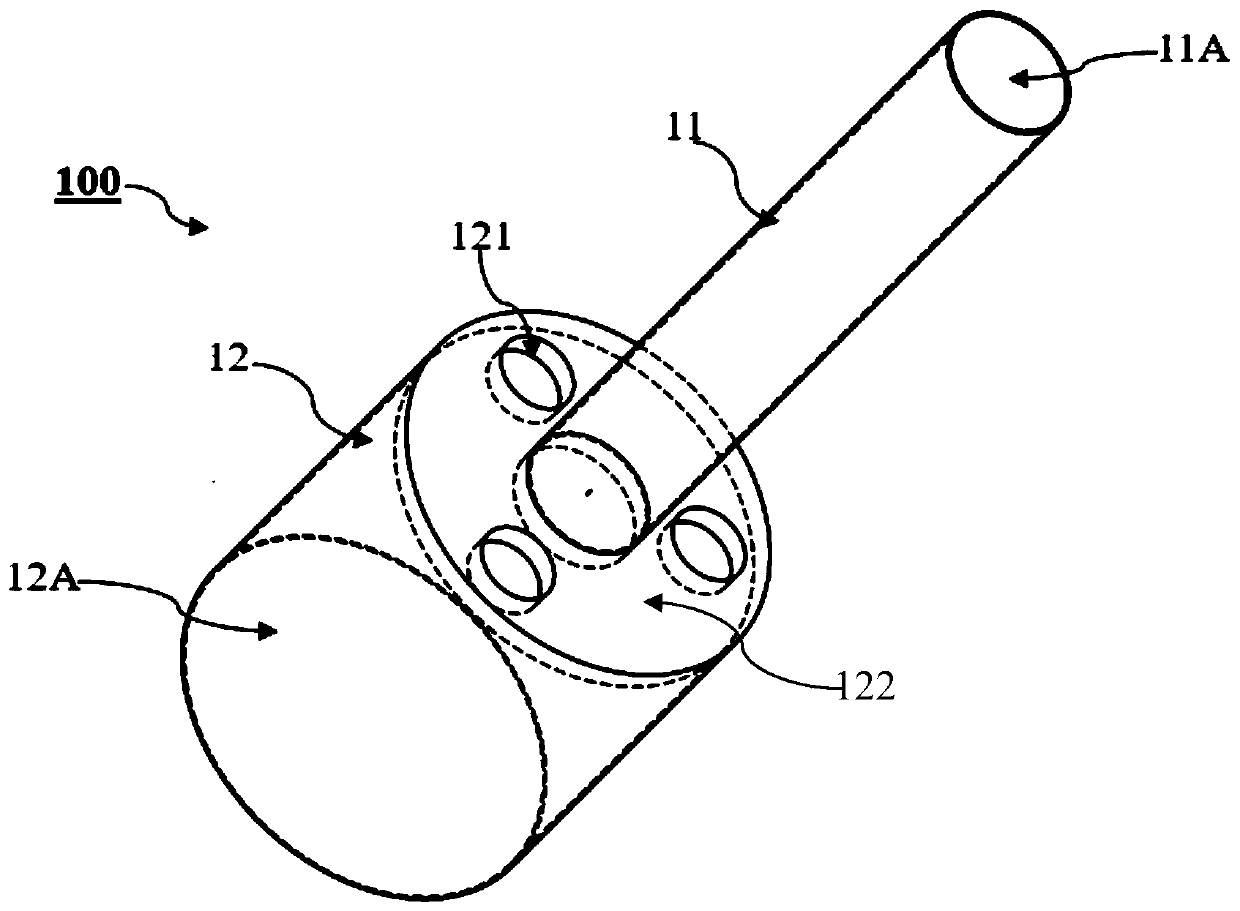

[0035] Such as figure 1 As shown in the figure, it is a schematic structural view of the tundish free-flow shroud structure in a preferred embodiment of the present invention. figure 1 It is a tundish free injection shroud structure 100, which includes: an upper pipe section 11 and a second pipe 12, inside which respectively form a pipe hole 11A and a pipe hole 12A, and the pipe hole 11A and the pipe hole 12A are in communication. Wherein, the lower pipe section 12 is connected below the upper pipe section 11 , and the inner diameter of the pipe hole 12A is larger than the inner diameter of the pipe hole 11A. Preferably, the inner diameter of the tube hole 12A is 2-4 times, in this embodiment, 3 times, the inner diameter of the tube hole 11A. Wherein, the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com