Application of argillaceous shale and method for repairing lead and other heavy metal contaminated soil by using argillaceous shale

A muddy shale and polluted soil technology, applied in the restoration, application, soil conditioning materials and other directions of polluted soil, can solve the problems of long bioremediation time, small scope of physical restoration, chemical restoration of secondary pollution, etc. Good compatibility with heavy metals, simple and diverse modification methods, and simple repair operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

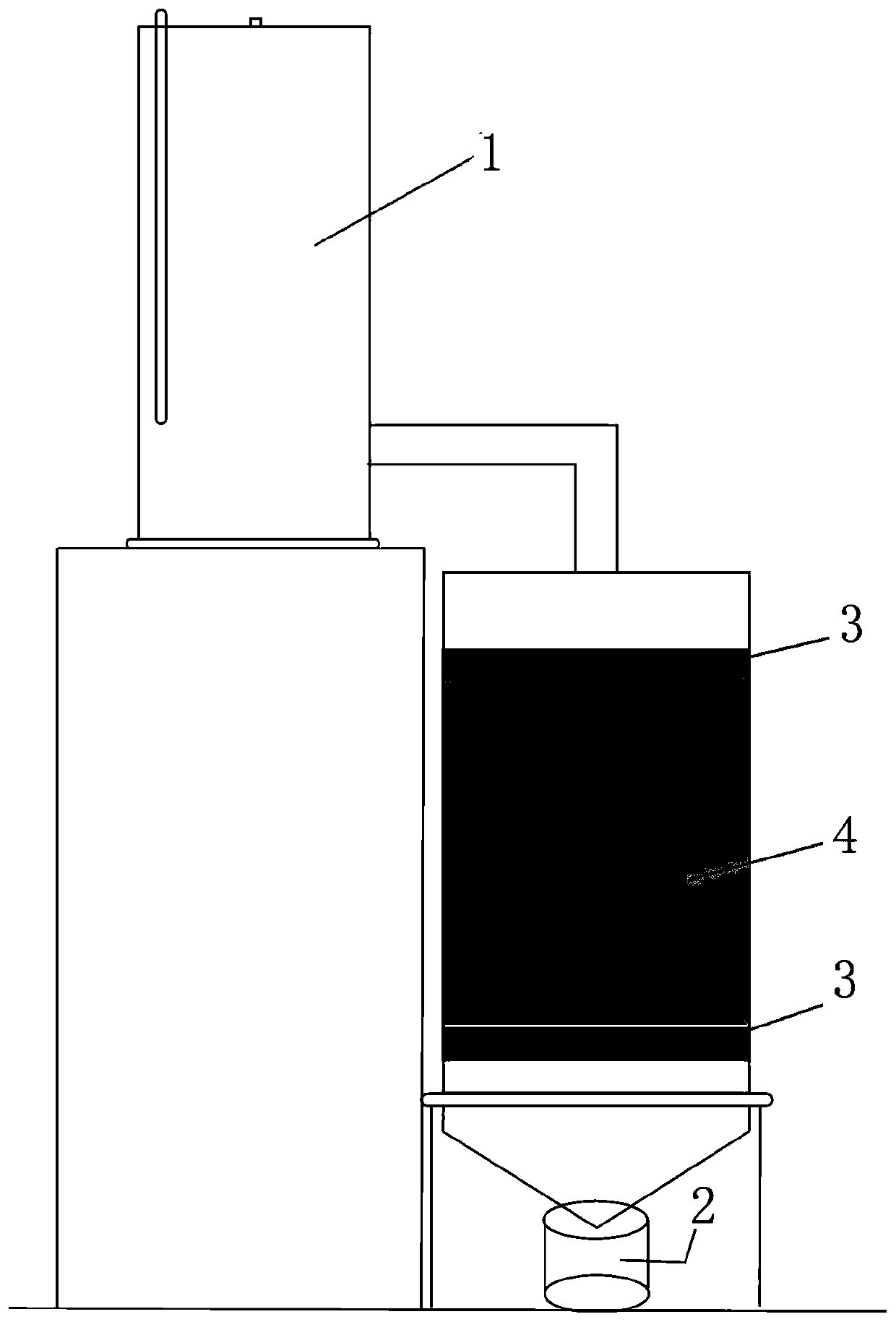

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

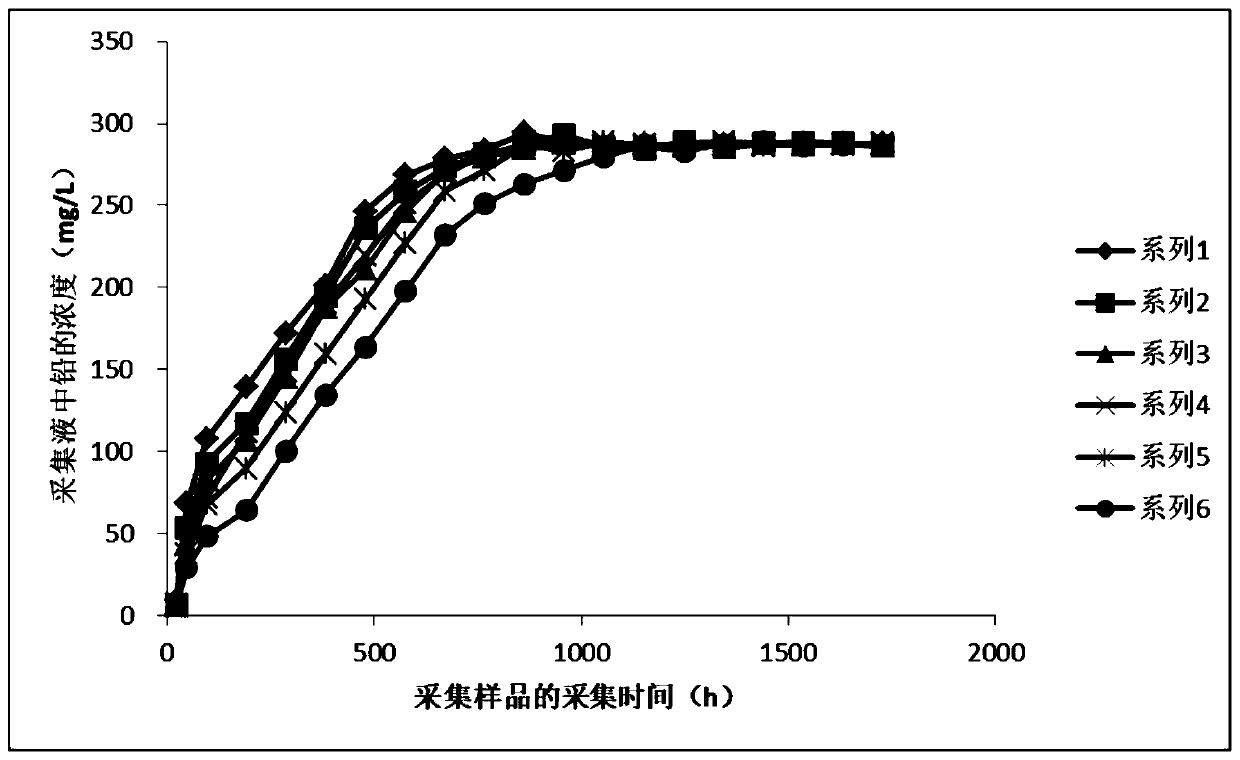

[0036] Firstly, the ratio test is carried out to screen the optimal particle size of the applied argillaceous shale:

[0037] The heavy metal in the polluted soil is Pb(II), but not limited to this heavy metal;

[0038] The argillaceous shale needs to be dried, ground and sieved, and the specific steps are as follows:

[0039] (1) The temperature in the oven is adjusted to 200°C, and the natural argillaceous shale and the field cultivation layer soil for testing are baked to constant weight;

[0040] (2) Grind the dried argillaceous shale and the soil of the field cultivation layer for testing, and pass through 10 mesh, 20 mesh, and 40 mesh nylon drying respectively after grinding;

[0041] (3) The pH of the above-mentioned argillaceous shale is 8.29, and the pH of the field plowing layer soil for testing is 8.14; the mineral composition co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com