Esterification reaction tower for producing glyceryl triacetate

A technology of glycerol acetate and esterification reaction, which is applied in the fields of carboxylate preparation, organic chemistry, chemical instruments and methods, etc., can solve the problems of long waiting time for recovery and shorten the reaction time, so as to reduce the difficulty of filtration and shorten the reaction time. , use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

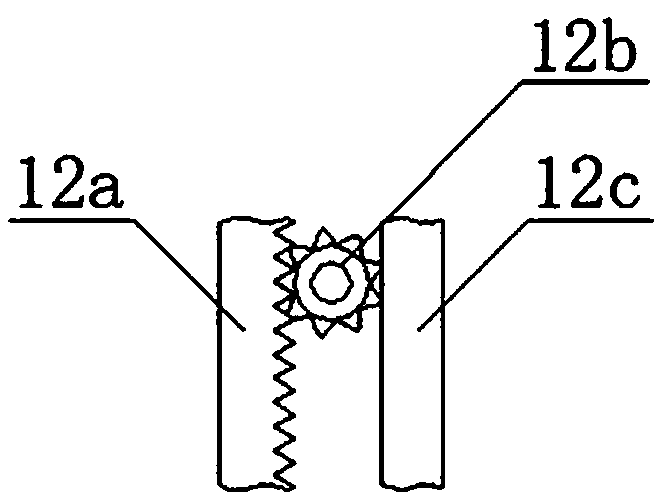

[0011] as attached Figure 1~Figure 3 The present invention shown comprises tower body 1, and the bottom of tower body 1 is provided with discharge valve, and the bottom of described tower body 1 is provided with reboiler 2, and the top in tower body 1 is provided with distributing plate 3, and distributing plate 3 Several vertical steam-guiding through-holes 4 are arranged inside, and several first condensers 5 are arranged outside the tower body 1, and the upper ends of the steam-guiding through-holes 4 are connected with the steam inlet end of the first condenser 5 through pipes, The first condenser 5 is in one-to-one correspondence with the steam guide through holes 4, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com