System and method for laser nitriding treatment of metal surface

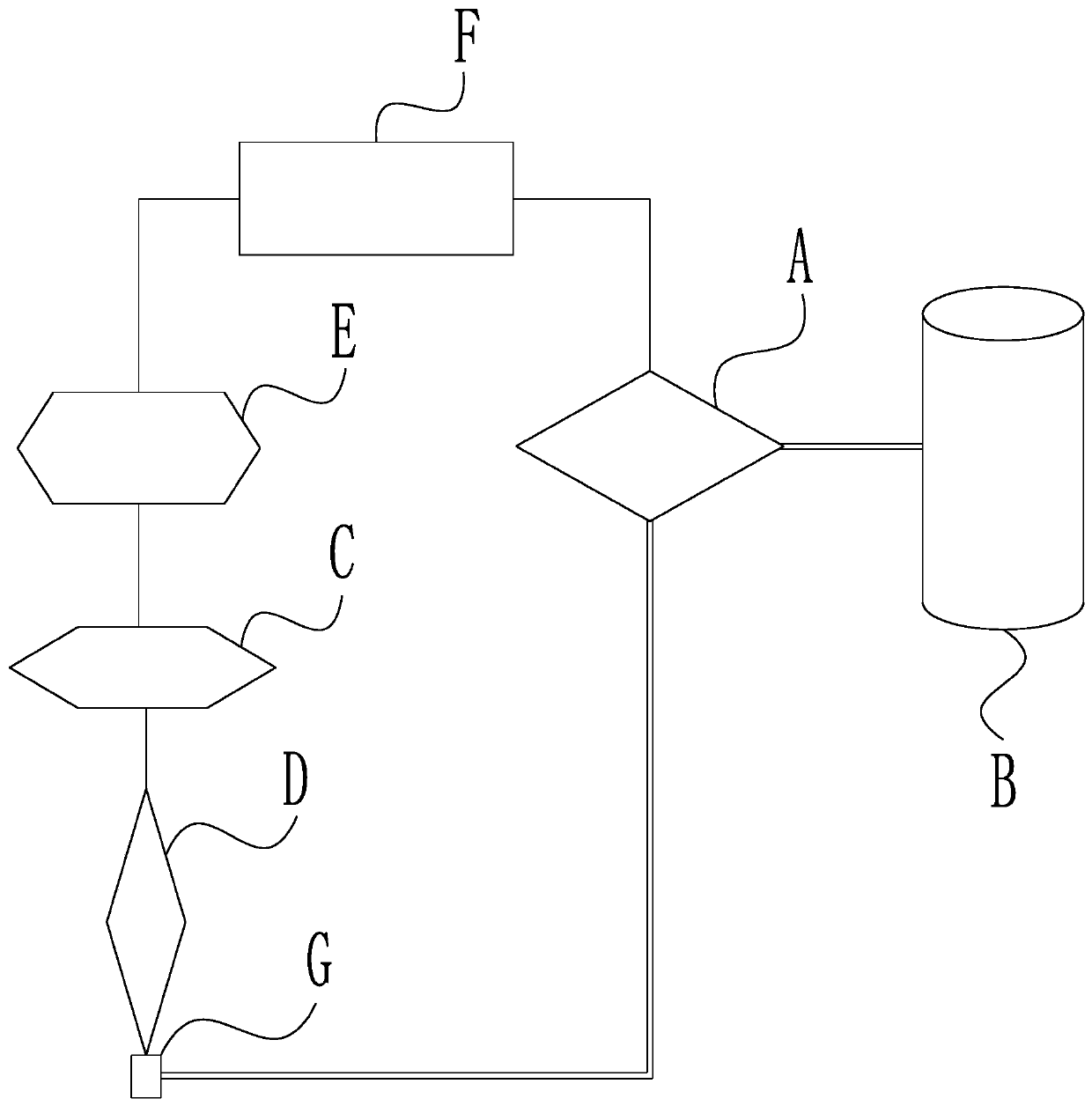

A metal surface, laser nitriding technology, applied in the direction of heat treatment equipment, heat treatment process control, metal material coating technology, etc., can solve the problems of high cost, high overall requirements, high requirements for personnel and matching, and achieve hardening The depth is easy to meet, the workers are easy to operate, and the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

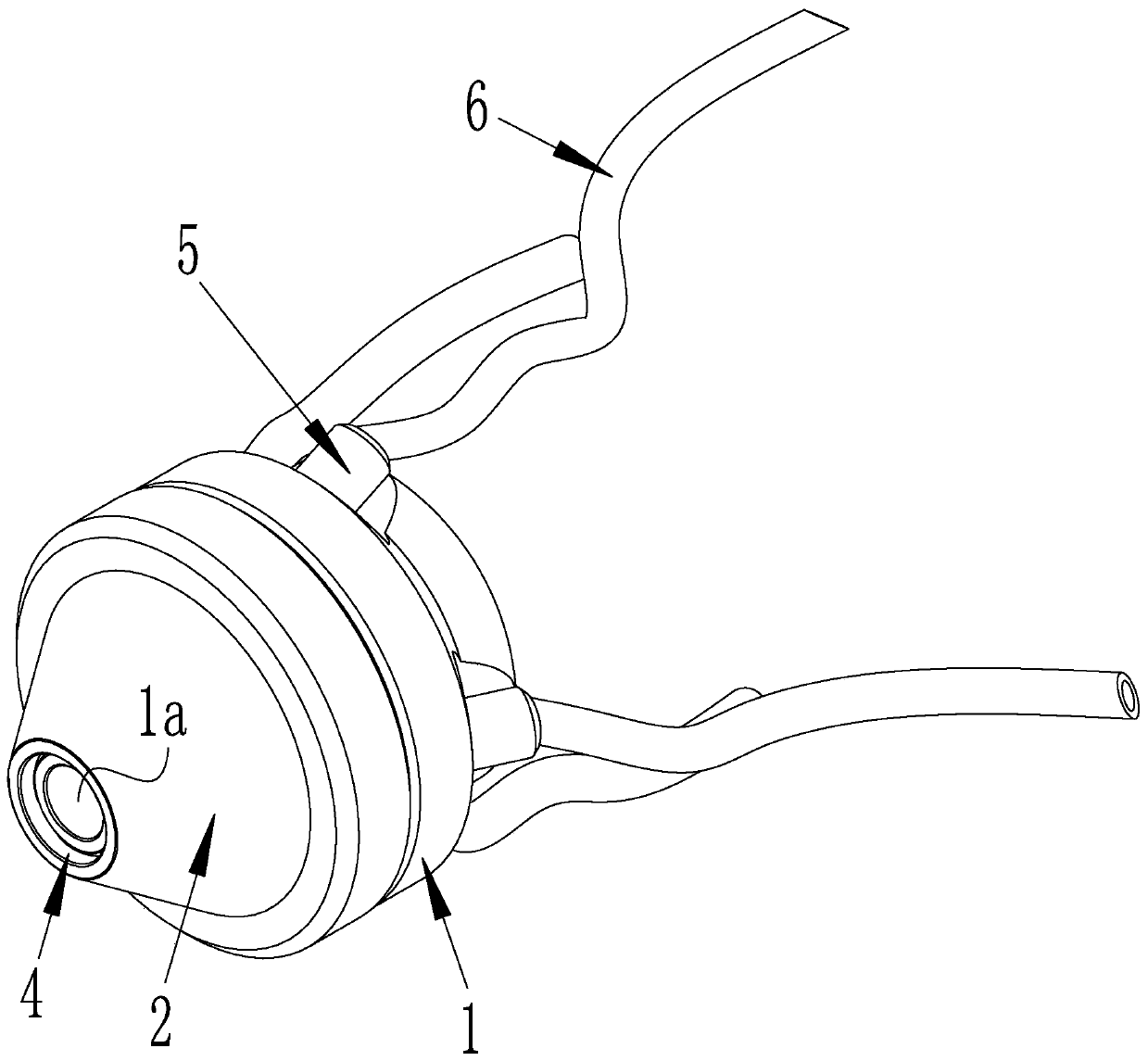

[0054] Embodiment 1: The laser spot emitted by the laser head D is a circular spot with a diameter of 0.4-1mm, the scanning power is 2000-4000W, and the continuous scanning speed is 100-200mm / min. Under this condition, the nitrogen is industrial nitrogen or high-purity nitrogen, preferably high-purity nitrogen. The feed rate of nitrogen gas is 30-80L / min, and the output pressure is 1.5-2MPa; the nitrogen atoms decomposed by laser irradiation are metallurgically bonded with the surface melted by laser heating, forming a nitride phase, and at the same time due to the self-cooling of the laser The blessing of hardening properties forms a composite layer of laser nitriding and quenching on the surface of the workpiece.

[0055] The surface of the workpiece treated by the laser nitriding and quenching composite process forms a nitrided and quenched composite layer with a thickness of 0.2-3mm, and the surface quality is good, without defects such as oxidation and decarburization. T...

Embodiment 2

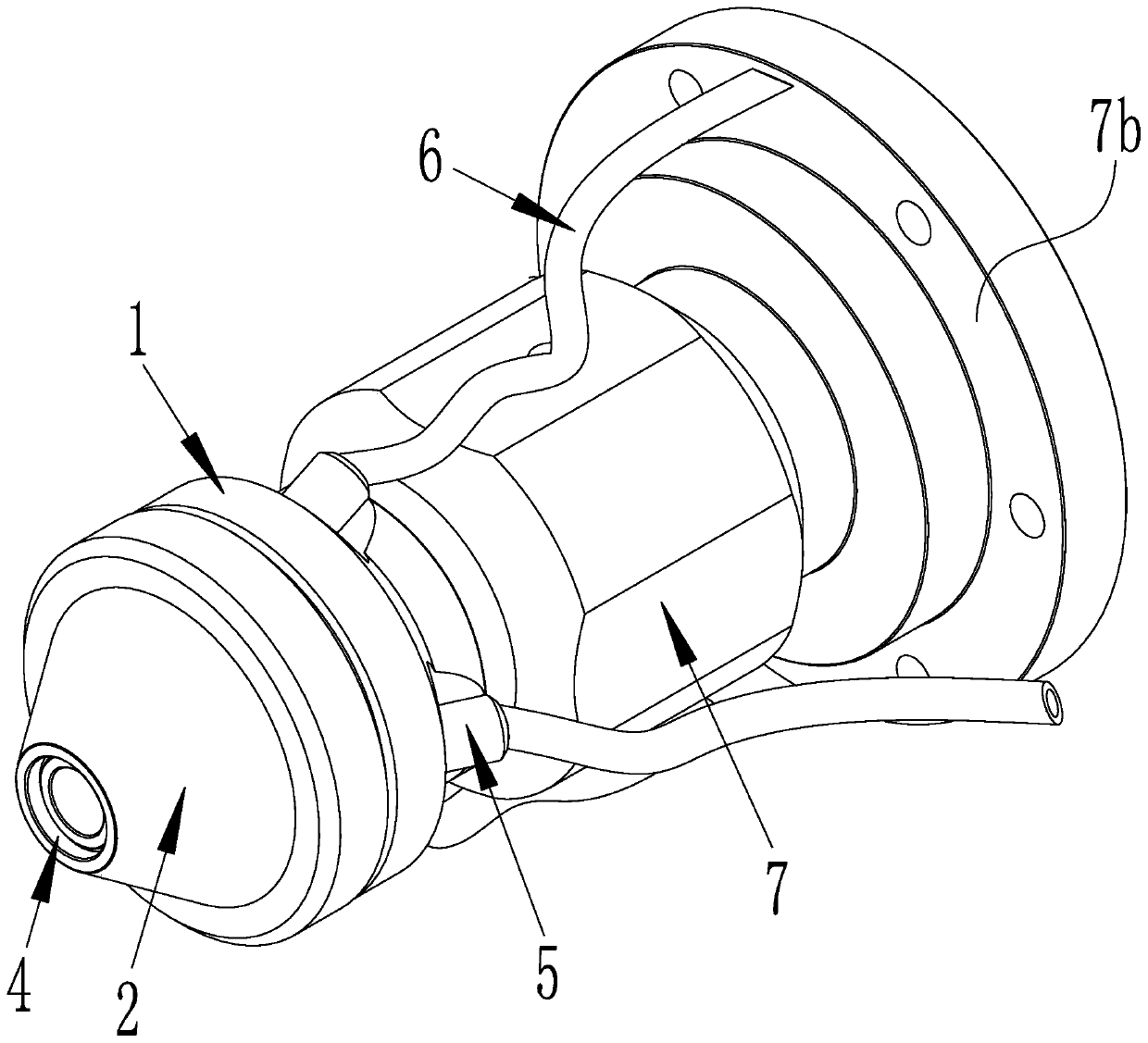

[0056] Example 2: The laser spot emitted by the laser head D is a square spot with a side length of 2-4mm, the scanning power is 6000W, and the continuous scanning speed is 50mm / min, 80mm / min, 100mm / min, 150mm / min in three groups, Verify 400mm separately 2 . Under this condition, nitrogen adopts industrial high-purity nitrogen. The feed rate of nitrogen gas is 60-100L / min, and the output pressure is 0.5-1MPa; the nitrogen atoms decomposed by laser irradiation are metallurgically bonded with the surface melted by laser heating, forming a nitride phase, and at the same time due to the self-cooling of the laser The blessing of hardening properties forms a composite layer of laser nitriding and quenching on the surface of the workpiece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com