Luminescent material for electric signboard and preparation process thereof

A technology of luminescent materials and signage, which is applied in the field of electric power, can solve the problems of affecting the luminous effect and the easy loss of long-lasting fluorescent materials, and achieve the effects of improving self-luminous effect, excellent wear resistance and high temperature resistance, and fast light energy speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

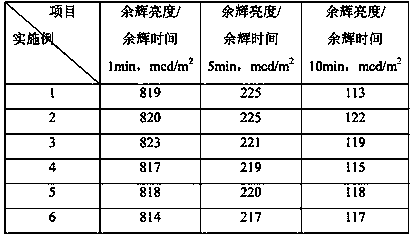

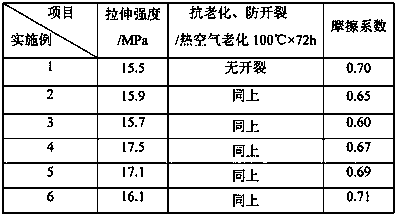

Examples

Embodiment 1

[0021] A luminescent material for power signboards, which is made of raw materials with the following weight fractions:

[0022] 65 parts of isophthalic acid unsaturated polyester resin, 15 parts of polyurethane resin, 40 parts of luminescent material, 3 parts of zinc stearate, 0.5 part of magnesium oxide, 5 parts of glass fiber, 0.5 part of hydroxy silicone oil, 0.2 part of ultraviolet absorber , 0.5 part of initiator, 0.1 part of drier and 15 parts of solvent.

[0023] The luminescent material is ZnS: Eu 2+ .

[0024] The ultraviolet absorber is UV-P.

[0025] The initiator is tert-butyl peroxide.

[0026] The drier is dibutyl tin dilaurate.

[0027] The solvent is isopropanol.

[0028] The above-mentioned preparation process of the luminescent material for the electric power sign board includes the following steps:

[0029] Mix isophthalic acid unsaturated polyester resin, polyurethane resin, light storage material, glass fiber, hydroxy silicone oil, ultraviolet absorber, initiator and...

Embodiment 2

[0032] A luminescent material for power signboards, which is made of raw materials with the following weight fractions:

[0033] 68 parts of isophthalic acid unsaturated polyester resin, 16 parts of polyurethane resin, 42 parts of luminescent material, 4 parts of zinc stearate, 0.6 part of magnesium oxide, 8 parts of glass fiber, 0.8 part of hydroxy silicone oil, 0.3 part of ultraviolet absorber , 0.8 parts of initiator, 0.2 parts of drier and 18 parts of solvent.

[0034] The light storage material is Ca 1-x Ba x S: Cu + , Eu 2+ .

[0035] The ultraviolet absorber is UV-9.

[0036] The initiator is tert-butyl peroxide.

[0037] The drier is dibutyl tin dilaurate.

[0038] The solvent is xylene.

[0039] The above-mentioned preparation process of the luminescent material for the electric power sign board includes the following steps:

[0040] Mix isophthalic acid unsaturated polyester resin, polyurethane resin, light storage material, glass fiber, hydroxy silicone oil, ultraviolet absorbe...

Embodiment 3

[0043] A luminescent material for power signboards, which is made of raw materials with the following weight fractions:

[0044] 70 parts of isophthalic acid unsaturated polyester resin, 18 parts of polyurethane resin, 45 parts of luminescent material, 6 parts of zinc stearate, 0.9 part of magnesium oxide, 9 parts of glass fiber, 1 part of hydroxy silicone oil, 0.4 part of ultraviolet absorber , 0.6 parts of initiator, 0.3 parts of drier and 20 parts of solvent.

[0045] The light storage material is Ca 1-x Sr x S: Eu 2+ , Dy 3+ .

[0046] The ultraviolet absorber is UV-0.

[0047] The initiator is tert-butyl peroxide.

[0048] The drier is dibutyl tin dilaurate.

[0049] The solvent is N,N-dimethylformamide.

[0050] The above-mentioned preparation process of the luminescent material for the electric power sign board includes the following steps:

[0051] Mix isophthalic acid unsaturated polyester resin, polyurethane resin, light storage material, glass fiber, hydroxy silicone oil, ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com