A kind of slope protection material and its preparation method, application and production equipment

A slope and mixture technology, applied in applications, other household appliances, ceramic products, etc., can solve problems such as soil dissolution, and achieve the effect of improving adsorption capacity, fast film forming speed, and strong slope protection ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A kind of slope protection material is provided in the present embodiment, and it is prepared by the raw material of following weight part:

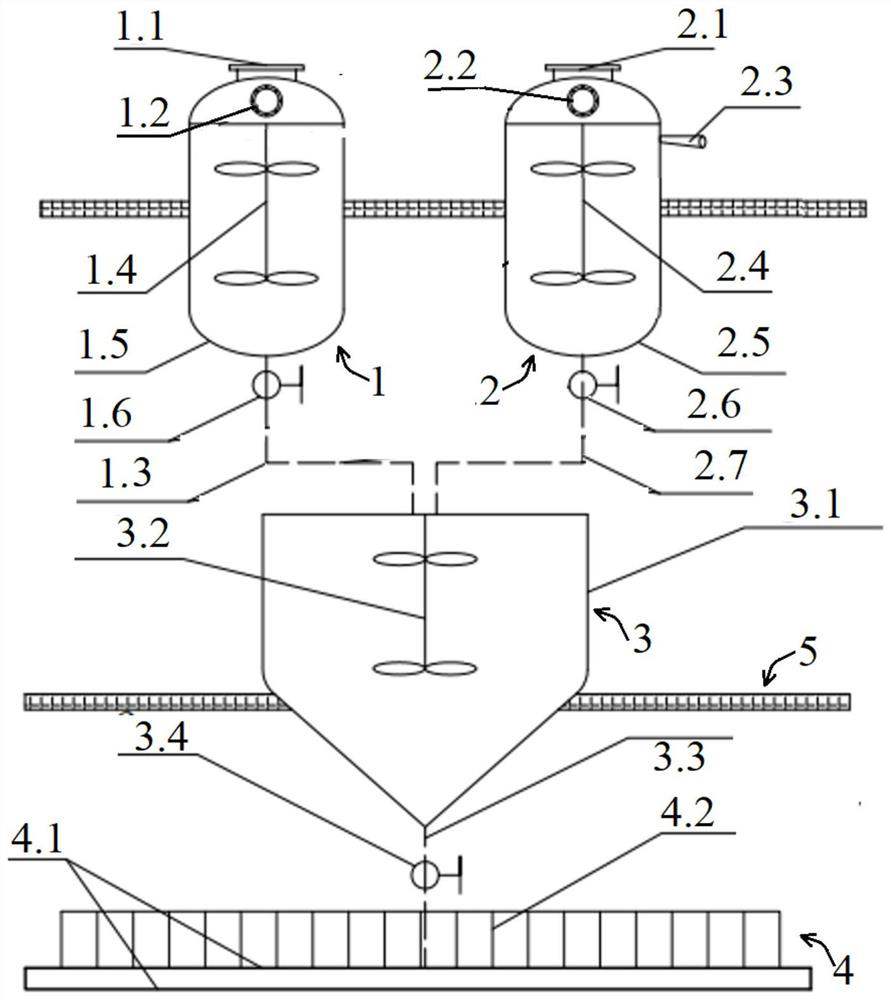

[0078] 30 parts of cement, 18 parts of fermented plant stalks, 2 parts of foaming agent, 50 parts of water; in the present embodiment, a feeding batch operation mode is adopted, and the pretreated plant stalks (with a particle size of 3 to 8 mm) and The inoculated sludge (the inoculum amount is 30% of the mass of the plant straw) is mixed evenly and sealed in a sealed mixing tank 1 for dry anaerobic fermentation. The fermentation temperature is controlled at 20°C to 50°C, and the fermentation time is 1 day. . Fermentation produced 375 mg / g of acetic acid with a carboxyl content of 78.95%.

[0079] Utilize the equipment among the embodiment 1 to prepare above-mentioned slope protection material, specifically comprise the following steps:

[0080] 1) Preparation of lightweight porous structure cement

[0081] Foaming agent and ce...

Embodiment 2

[0089] A kind of slope protection material is provided in the present embodiment, and it is prepared by the raw material of following weight part:

[0090] 40 parts of cement, 10 parts of fermented plant straw, 10 parts of foaming agent, 40 parts of water;

[0091]In this embodiment, the batch operation mode of feeding at one time is adopted, and the pretreated plant stalks (with a particle size of 3-8mm) and the inoculation sludge (the inoculum amount is 30% of the mass of the plant stalks) are evenly mixed and sealed in a sealed mixing tank 1 , dry anaerobic fermentation is carried out, the fermentation temperature is controlled at 20°C to 50°C, and the fermentation time is 3 days. Fermentation yielded 425 mg / g with a carboxyl content of 78.95%.

[0092] Utilize the equipment among the embodiment 1 to prepare above-mentioned slope protection material, specifically comprise the following steps:

[0093] 1) Preparation of lightweight porous structure cement

[0094] Foaming...

Embodiment 3

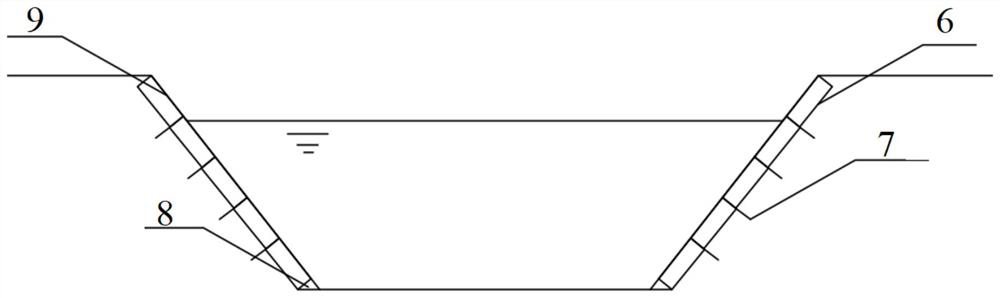

[0102] Now for the plain river network area, a certain river section uses the slope protection material produced in the present invention to carry out slope care, according to figure 2 In this way, the slope protection material is laid on the river bank slope. Specific steps are as follows:

[0103] 1. Leveling the slope of the river bank 9;

[0104] 2. Concrete structure cushion 8 is poured on the bottom surface of the river channel;

[0105] 3, start from the concrete structure cushion 8 on the bottom surface of the river, gradually carry out close laying to the riverbank slope 9 top, utilize the stainless steel plate 7 to fix the position of each piece of slope protection material 6.

[0106] The main pollutant indicators in the river water body are COD, ammonia nitrogen, total nitrogen and total phosphorus. After the slope protection material provided in the present invention is laid, a biofilm is formed on the surface of the slope protection material. The content of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com