A kind of preparation method of egg yolk type Fenton microreactor loaded with precious metal nanoparticles on the inner surface

A micro-reactor and nano-particle technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, oxidized water/sewage treatment, etc. Low problems, to avoid aggregation, high stability, and improve the effect of decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

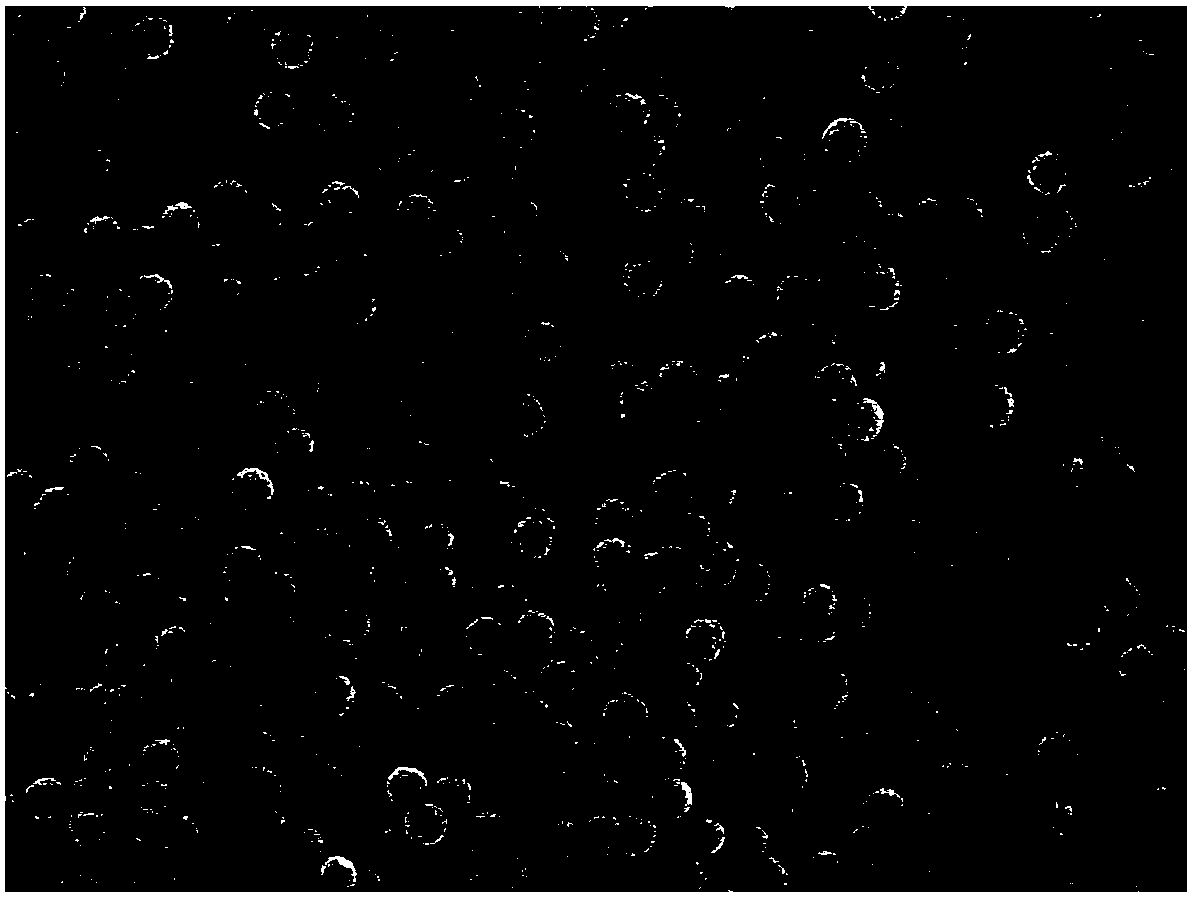

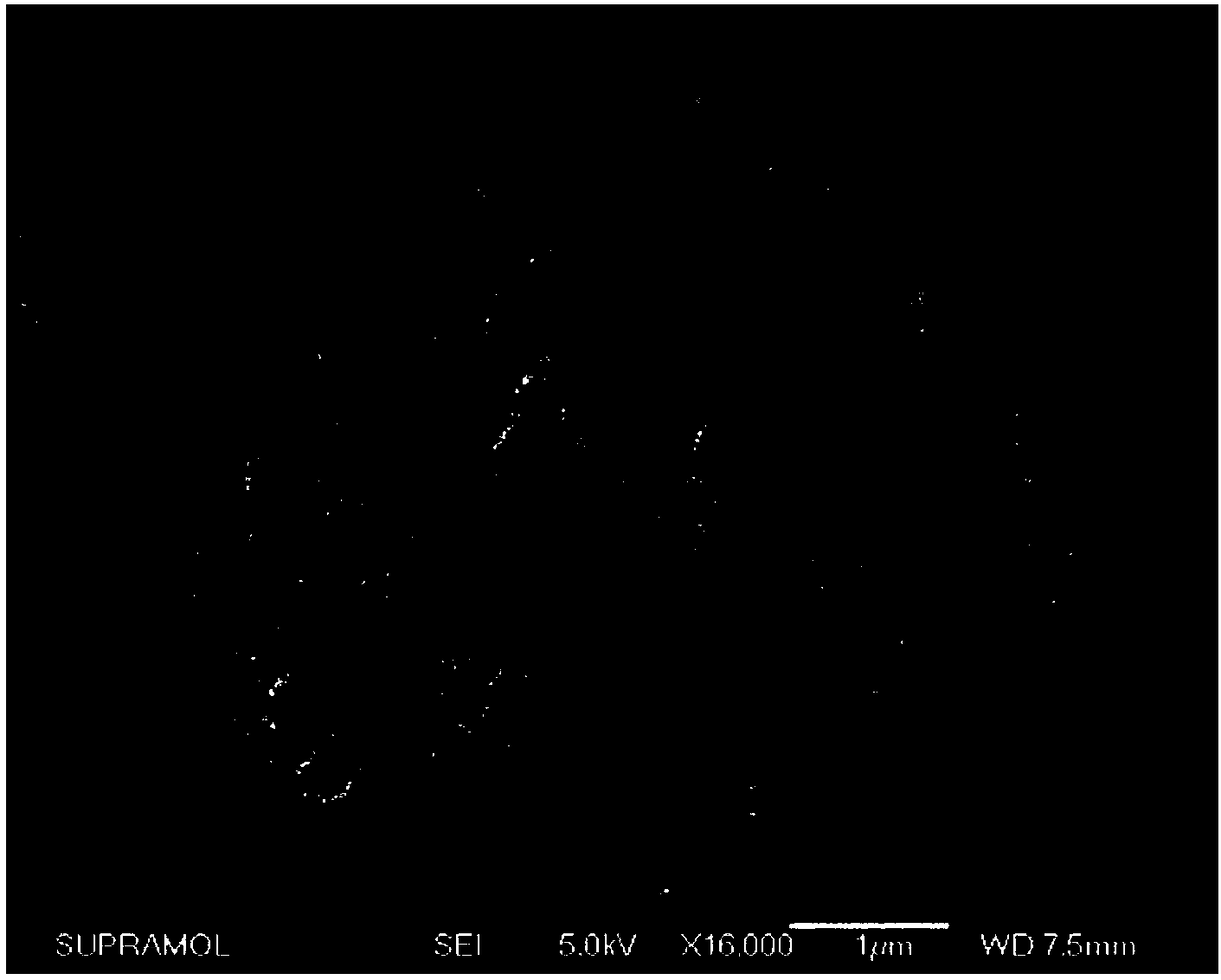

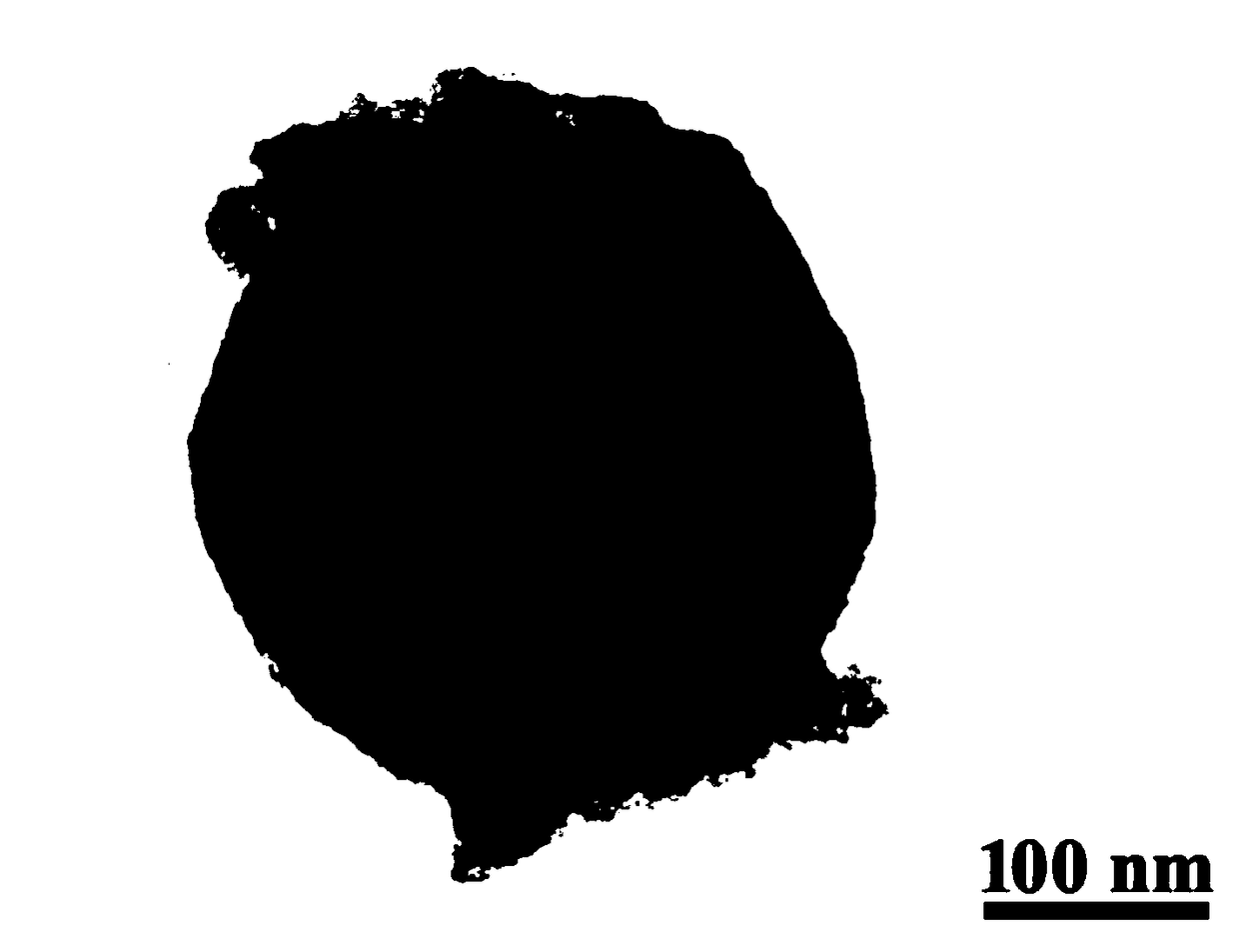

[0029] Specific implementation mode one: the preparation method of the egg yolk type Fenton microreactor loaded with noble metal nanoparticles on the inner surface of the present implementation mode comprises the following steps:

[0030] 1. Disperse the magnetic nanoparticles into water, then add ethyl orthosilicate to a final concentration of 1mg / mL-30mg / mL, stir for 2-3min, then add ammonia water to a final concentration of 0.01mg / mL-1mg / mL, React for 6-12h to obtain product A;

[0031] 2. Add the product A into the noble metal salt solution, wherein the final concentration of the noble metal salt is 0.1mg / mL~10mg / mL, after stirring for 10min~30min, add the reducing agent until the final concentration is 1mg / mL~50mg / mL, and react for 10min ~60min, product B was obtained;

[0032] 3. Disperse the product B in the conductive polymer monomer, wherein the final concentration of the conductive polymer monomer is 10 mg / mL-100 mg / mL, and add an initiator until the final concentra...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment differs from Embodiment 1 in that the magnetic nanoparticles described in step 1 are ferric oxide, ferric oxide or iron oxyhydroxide. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, tetraethyl orthosilicate is added to a final concentration of 5 mg / mL-25 mg / mL. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com