Livestock and poultry breeding wastewater treatment device and method

A livestock and poultry breeding wastewater and treatment device technology, applied in the field of wastewater treatment, can solve the problems that the breeding wastewater cannot meet the wastewater discharge standard stably, the breeding wastewater treatment process is backward, and pollute the water body, etc., so as to improve the decolorization and disinfection effect and reduce the sludge Yield, effect of preventing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

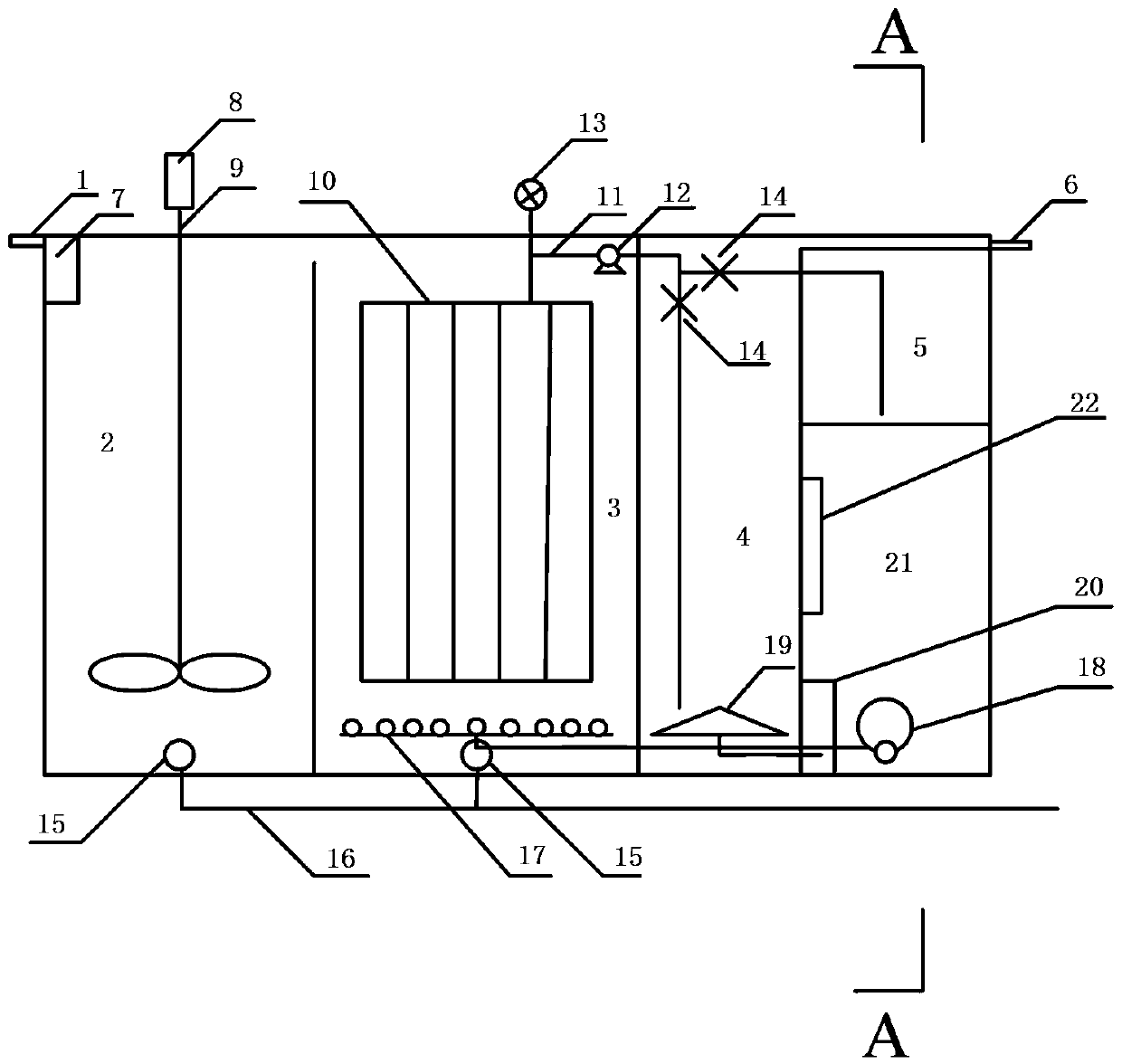

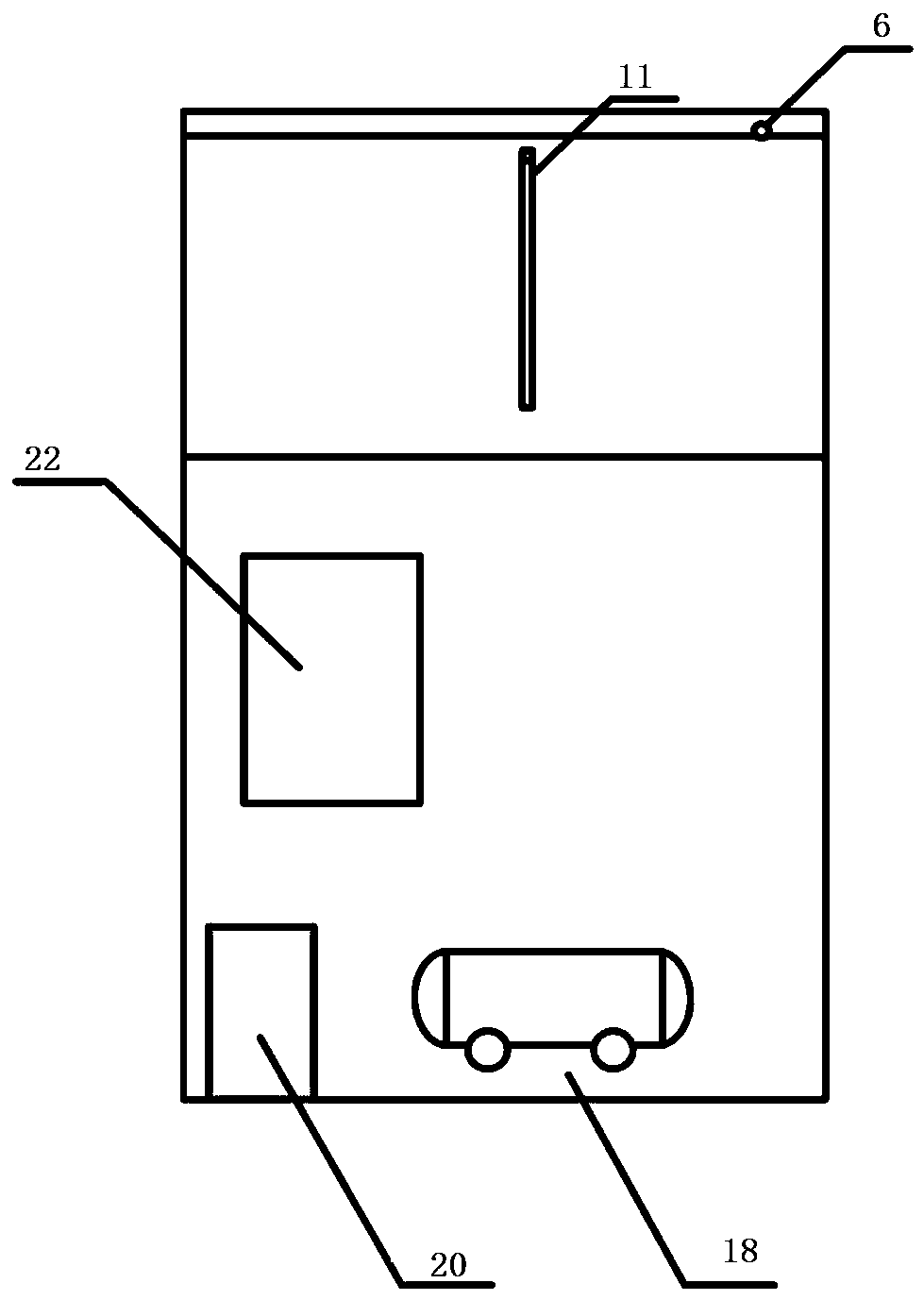

[0042] Embodiment 1: Integrated livestock and poultry breeding wastewater treatment device, the device is an integrated container structure, including anaerobic zone 2, aerobic zone 3, ozone zone 4, backwash liquid storage zone 5 and equipment operation zone arranged in sequence twenty one. Described anaerobic zone 2 comprises water inlet and water inlet pipe 1, and water inlet is also provided with filter 7, and filter screen adopts mechanical slag removal, places anaerobic zone inside. The top of the anaerobic zone is provided with a stirring motor 8, and the stirring motor drives the agitator 9 to stir, and the bottom is provided with a mud discharge port 15 and a mud discharge pipe 16. The aerobic zone is provided with a membrane module 10, the membrane module is connected to the bottom of the ozone zone 4 and the backwash liquid storage zone 5 through a liquid connection pipe 11, a pressure gauge 13 and a suction pump 12 are installed on the liquid connection pipe, Valve...

Embodiment 2

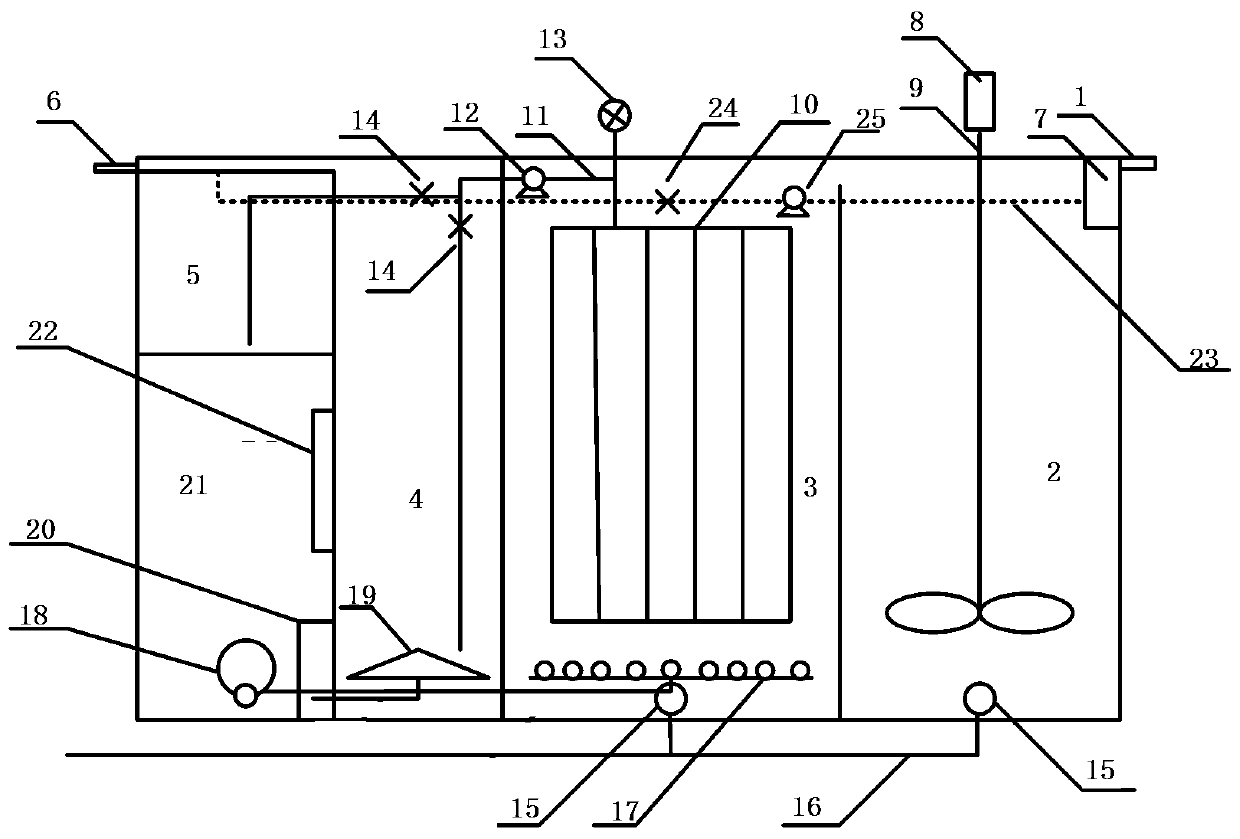

[0050] like image 3 Shown, identical with the structure of embodiment 1, difference is also to be provided with sewage backflow pipe 23, backflow valve 24 and backflow pump 25 between the ozone zone overflow port and the anaerobic zone. One end of the sewage return pipe is connected to the filter, and the other end is connected to the overflow port of the ozone zone. The sewage return pipe is provided with a valve and a return pump. In order to prevent the effluent after primary treatment from failing to meet the discharge standard, the above-mentioned structure is set up. If the effluent can meet the standard after primary treatment, the wastewater does not need to be refluxed for secondary treatment.

[0051] The device provided by Embodiment 1 and Embodiment 2 of the present invention has a good treatment effect on rural small-scale standardized pig farm wastewater. Taking the processing device in Embodiment 1 as an example, the pig wastewater is treated by a period of two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com