Method and device for improving interlayer bonding force of fiber reinforced building plate

An interlayer bonding force and building board technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as poor interlayer bonding force and product anisotropy, and achieve low transformation cost, performance improvement, Good production flexibility and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A method for improving the bonding force between layers of fiber-reinforced building boards, specifically comprising the following steps:

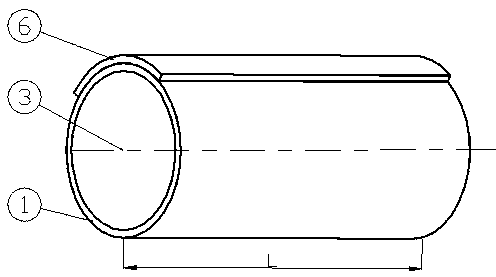

[0031] a. The forming cylinder is rotated to increase the slurry layer by layer, forming a layer-by-layer wet billet on the forming cylinder.

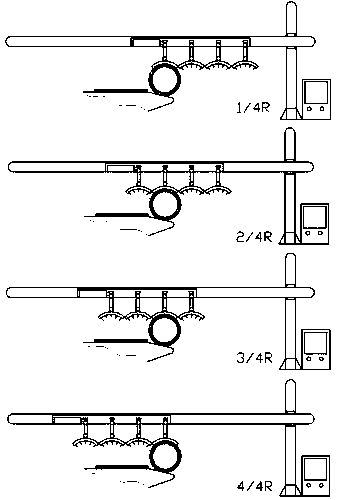

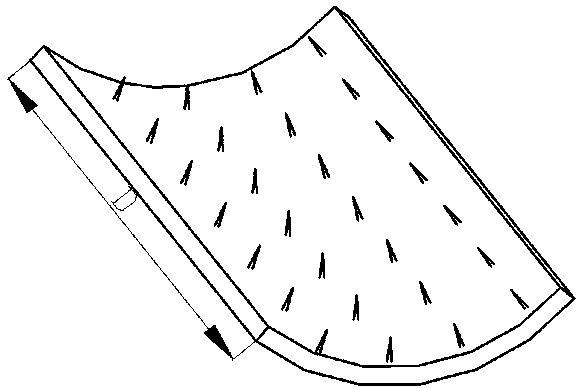

[0032] b. At a certain distance above the forming cylinder, set several arc-shaped needle-punched tiles and an elliptical closed running track for the free movement of several arc-shaped needle-punched tiles. The first arc-shaped needle-punched tile has a traction motor. A certain number of array needles are distributed on each arc-shaped needle-punched tile, and the array needles are placed perpendicular to the arc surface. The length D of each arc-shaped needle-punched tile is the width L of the wet billet, and the radian of each arc-shaped needle-punched tile is A part of the circumference of the forming cylinder, the total arc of several arc-shaped acupuncture tiles is the entire circumf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com