Asynchronous and simultaneous separation process of poor and difficult nickel-copper ore

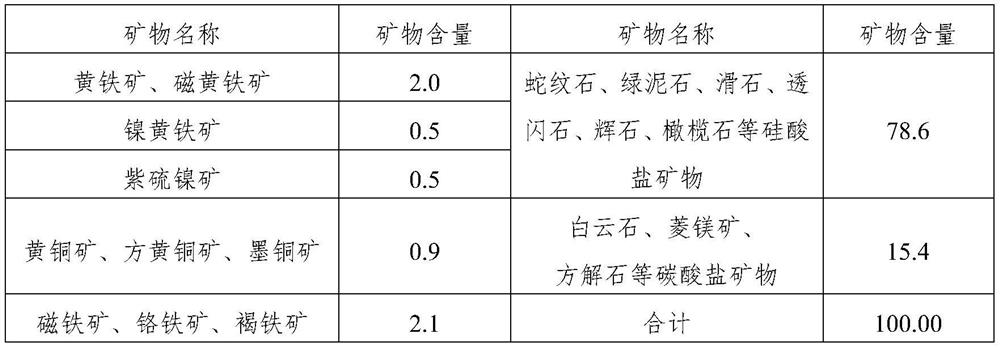

A technology for copper ore and refractory beneficiation, which is applied in the field of asynchronous simultaneous separation of lean and refractory nickel-copper ore, and can solve the problems affecting the recovery of chalcopyrite, pyrite, pyrite, and nickel-copper metal recovery. It can improve the efficiency of each flotation operation, improve the efficiency of each flotation operation, and increase the recovery rate improvement space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

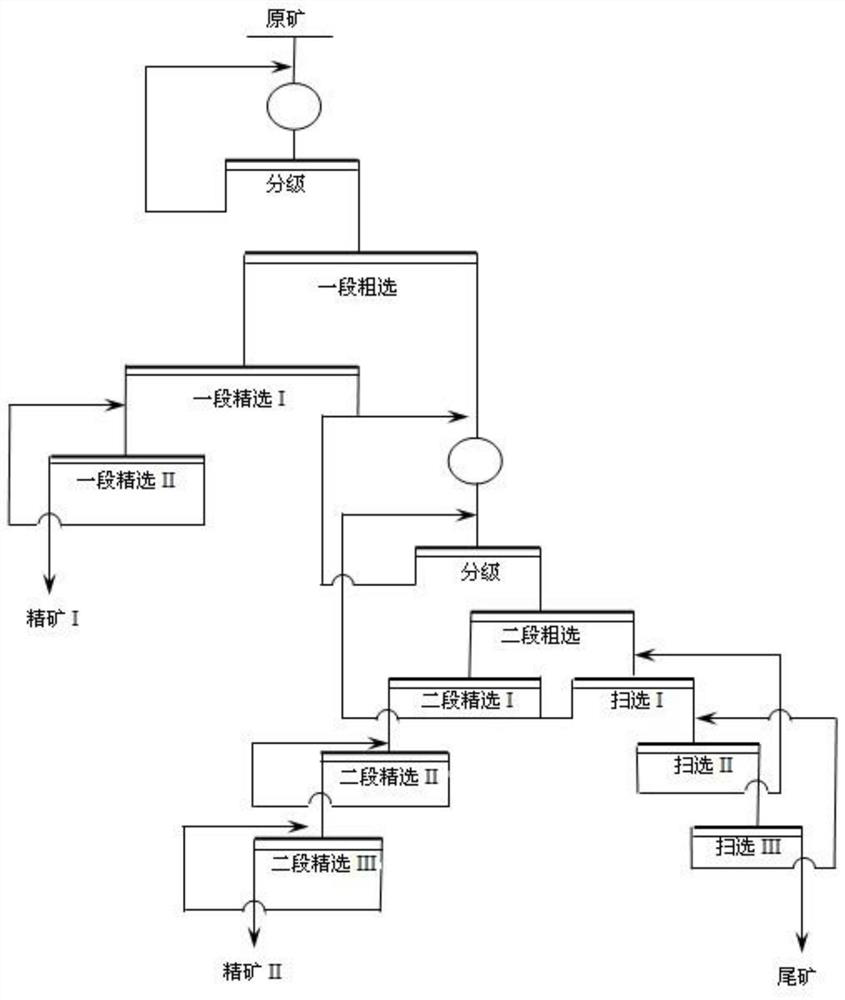

Method used

Image

Examples

Embodiment 1

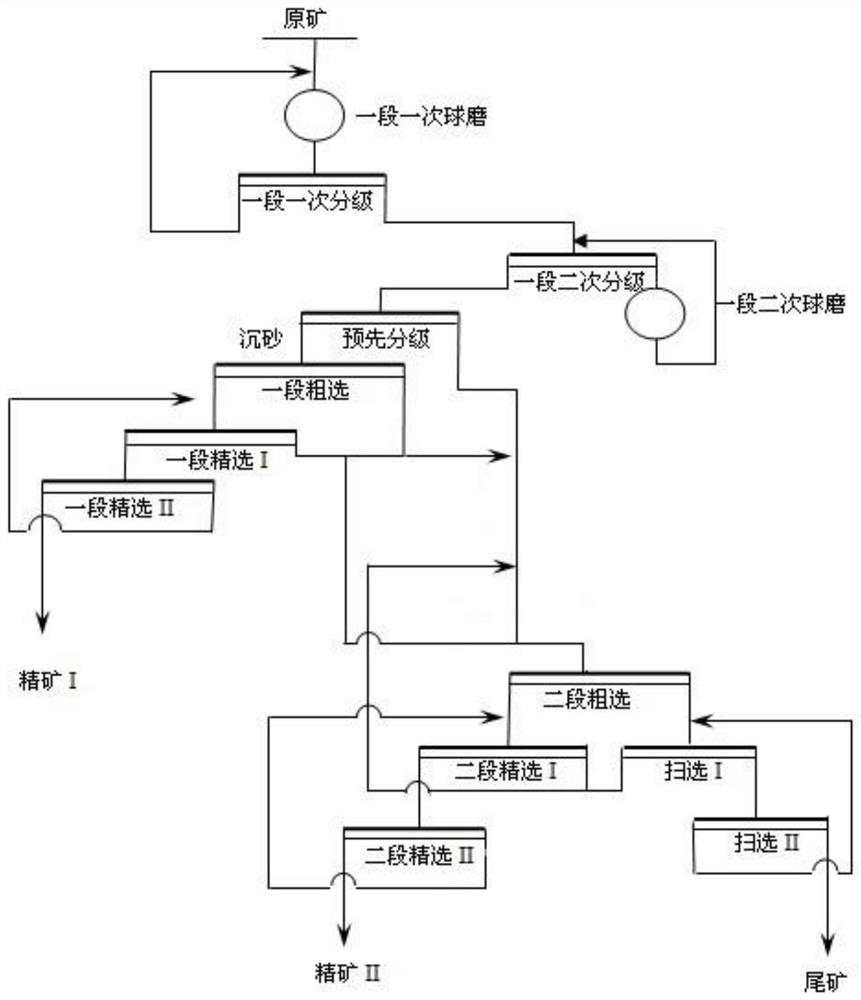

[0050] Step (1): Grinding and dissociating the raw ore of poor and refractory nickel-copper ore with a nickel grade of 0.65% and a copper grade of 0.54% through a one-stage ball mill until the mass percentage of the grinding fineness -200 mesh is 65%~ After 70%, add water and stir to obtain the pulp, and use the cyclone to classify the pulp to obtain a stage of graded grit A2 and a stage of grinding overflow pulp A1 with a concentration of 67%-73%; a stage of graded grit A2 returns to a primary ball mill for processing Grinding again forms a closed loop.

[0051] Step (2): Pass the first-stage grinding overflow slurry A1 obtained in step (1) as a raw ore for secondary grinding A section of secondary overflow ball mill is used for secondary dissociation, and then a section of secondary cyclone is used for classification to obtain a section of secondary overflow pulp A3 and a section of secondary sand settling A4. A section of secondary sand settling A4 returns to a section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com