Nitrogen-doped graphene composite material supported by ag-cus core-shell microspheres, preparation method and application thereof

A technology of nitrogen-doped graphene and composite materials, which is applied to the analysis of materials, electrochemical variables of materials, and material analysis through electromagnetic means, and can solve problems such as low detection limits, high detection limits, and narrow detection ranges. Achieve the effects of low detection limit, wide detection range, detection range and detection limit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0039] Example 1 Preparation of Nitrogen-Doped Graphene Composites Supported by Ag-CuS Core-Shell Microspheres

[0040] (1) Synthesis of CuS microspheres: Weigh 0.4 mmol of cupric chloride dihydrate and 1 mmol of thiourea into a small beaker, add 7.5 mL of deionized water and 7.5 mL of N,N-dimethylformamide, stir magnetically for 45 min, The mixed solution was transferred to a polytetrafluoroethylene-lined hydrothermal reactor, and the reactor was placed in an oven at 170°C for constant temperature reaction for 6 hours. After the reaction was completed, it was naturally cooled to room temperature. Deionized water was washed three times to obtain CuS microspheres;

[0041] (2) Preparation of CuS microsphere dispersion: Disperse the obtained CuS microspheres in 5 mL of water, and add 0.75 g of glucose under vigorous stirring to obtain a CuS microsphere dispersion;

[0042] (3) Preparation of silver ammonia solution: 0.1g AgNO 3 Dissolve in 1 mL of water, slowly add 0.55 mol / L ...

Embodiment 1

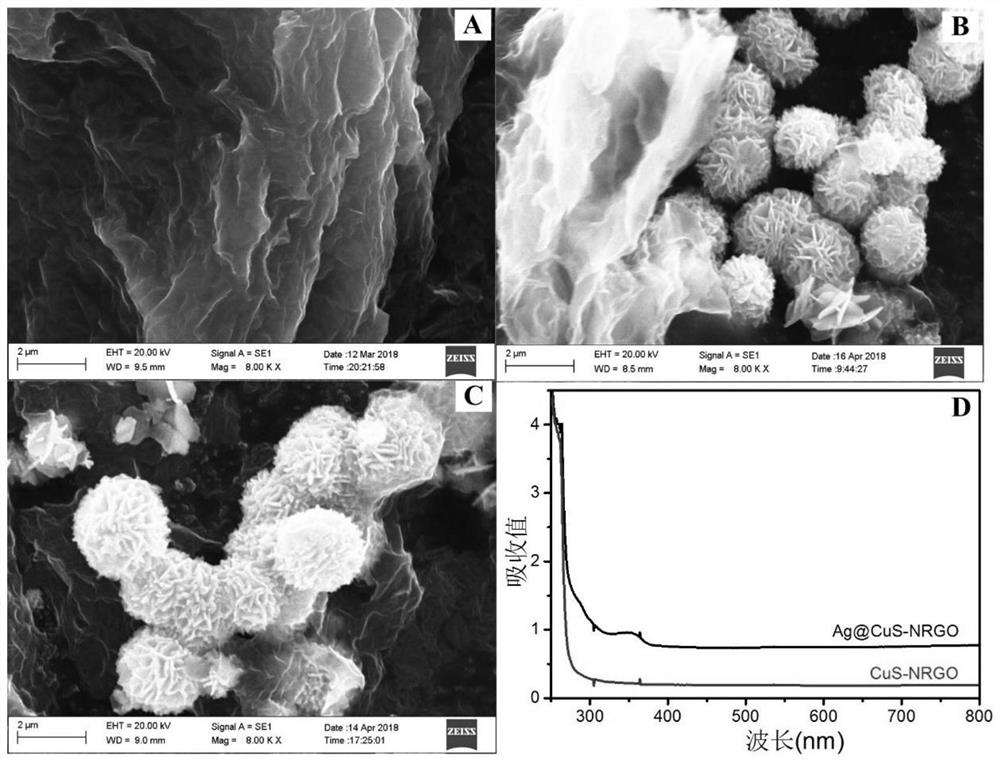

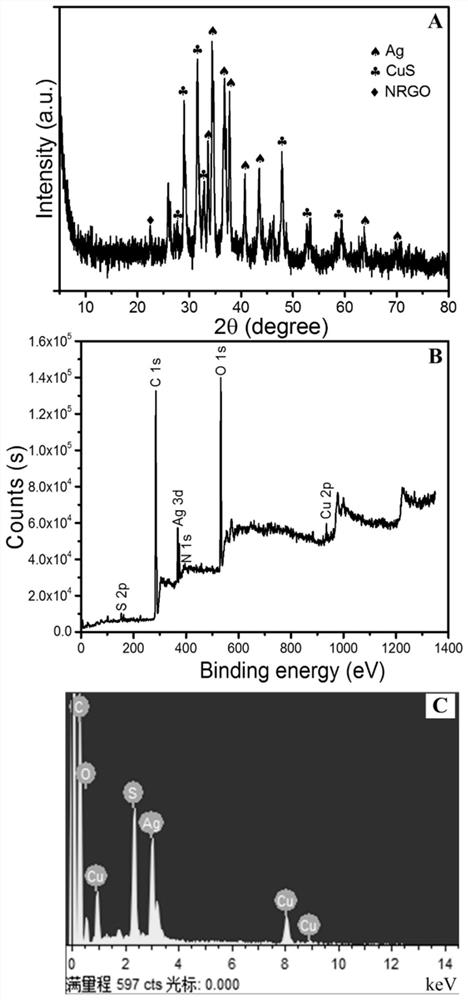

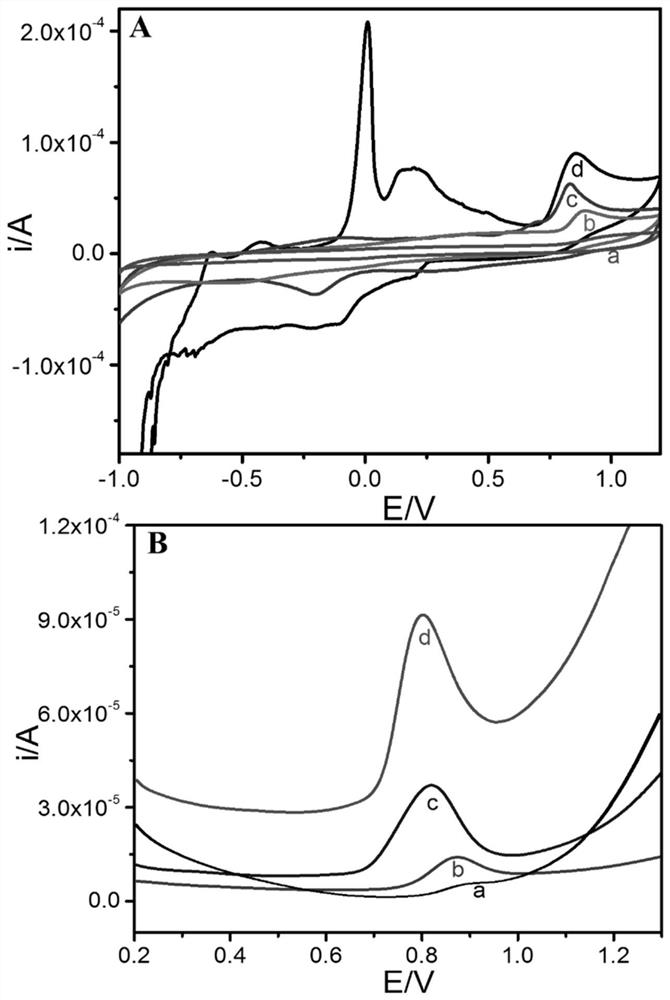

[0049] The morphology and optical characteristics of the Ag-CuS core-shell microsphere-supported nitrogen-doped graphene composite prepared in Example 1 are as follows: figure 1 SEM images of nitrogen-doped graphene (A), nitrogen-doped graphene composites supported by CuS microspheres (B), and nitrogen-doped graphene composites supported by Ag-CuS core-shell microspheres (C); And the UV spectra of nitrogen-doped graphene composites supported by CuS microspheres and nitrogen-doped graphene composites supported by Ag-CuS core-shell microspheres (D). from figure 1 (A) It can be seen that the surface with nitrogen-doped graphene has more obvious wrinkles, which are caused by nitrogen doping, and this multi-wrinkled surface is beneficial to its loaded metal particles. from figure 1 (B) It can be seen that the CuS microspheres are supported on the surface of nitrogen-doped graphene. The CuS microspheres are constructed from nanosheets, and the overall appearance of the microsphere...

Embodiment 2A

[0051] Example 2 Preparation of Nitrogen-Doped Graphene Composite Modified Electrode Supported by Ag-CuS Core-Shell Microspheres

[0052] Utilize 0.3 μm and 0.05 μm Al 2 O 3 Polish the glassy carbon electrode (diameter 3mm) on sandpaper to a smooth mirror surface, then ultrasonically clean the glassy carbon electrode with 1:1 dilute nitric acid, acetone and distilled water for 5 minutes, and then bake it under infrared light until it is ready for use. Good glassy carbon electrode. Then, 1 mg of the nitrogen-doped graphene composite material supported by Ag-CuS core-shell microspheres prepared in Example 1 was added to 3 mL of N,N-dimethylformamide, and after ultrasonic dispersion for 10 min, the Ag-CuS core-shell was obtained The dispersion liquid of the nitrogen-doped graphene composite material supported by the microspheres was added dropwise on the surface of the treated glassy carbon electrode with 7 μL of the dispersion liquid, and dried under the irradiation of an infr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com