Hexagonal detachable welded heat exchanger

A heat exchanger and hexagonal technology, which is applied in the field of hexagonal detachable welded heat exchangers, can solve the problems of large limitations, difficulties in popularization and use, and difficulty, and achieves a wide range of applications and flexible nozzle orientation settings. , Simple processing and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the drawings and specific embodiments.

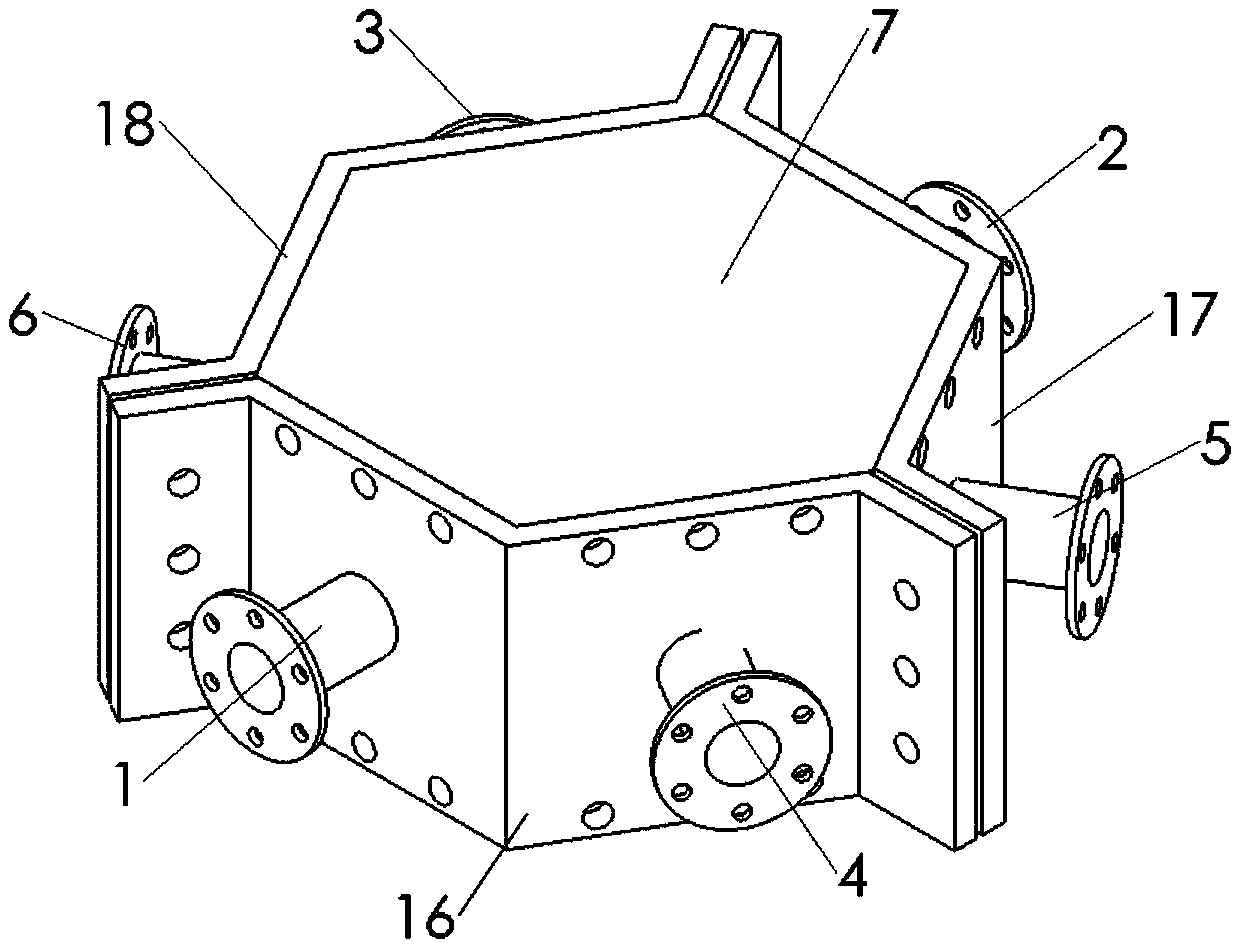

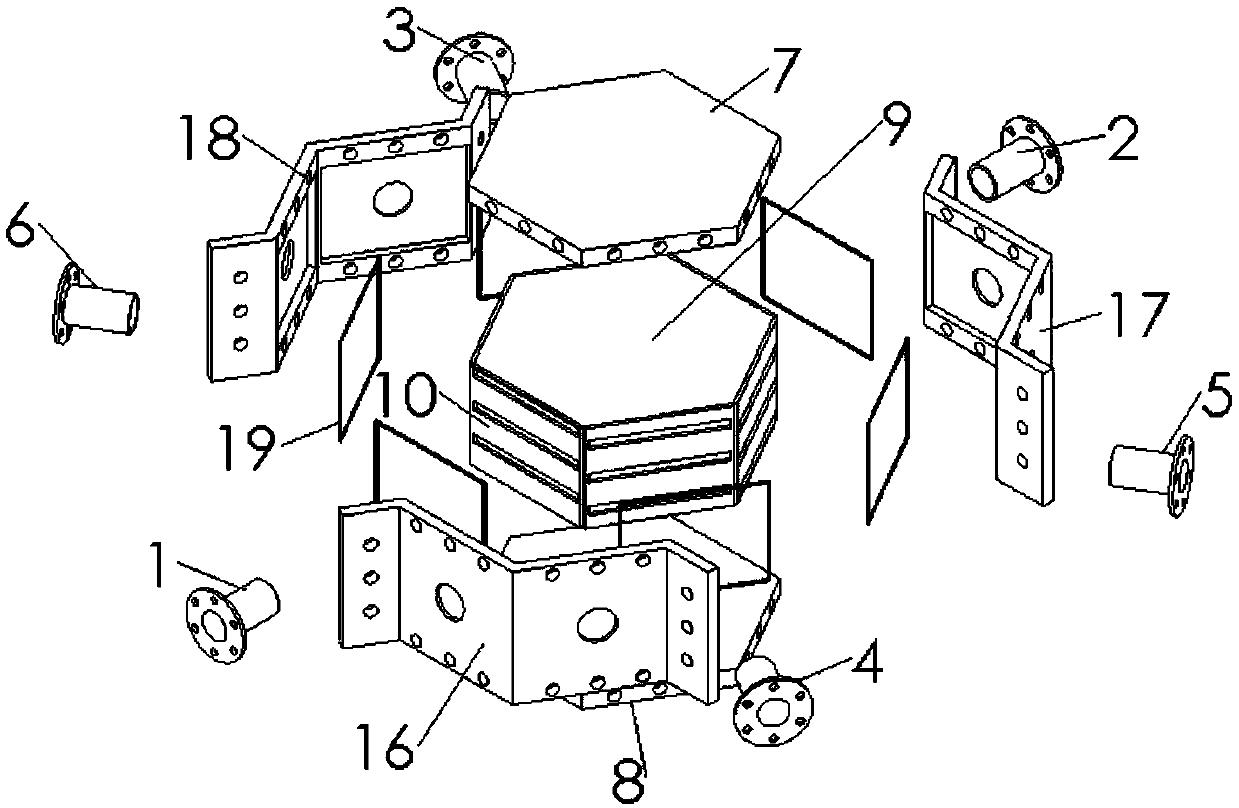

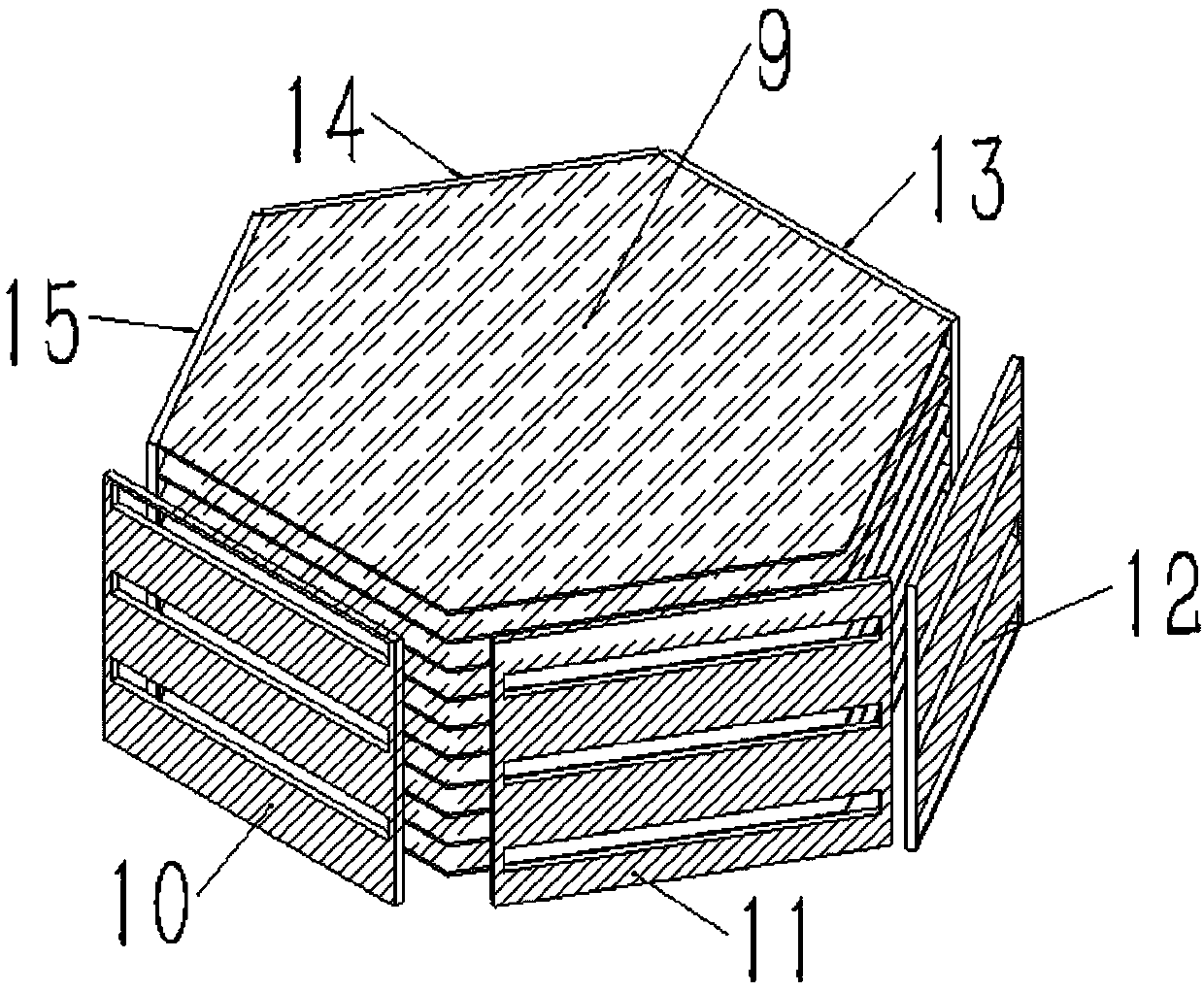

[0035] Such as figure 1 , 2 As shown, the hexagonal heat exchanger of the present invention includes fluid side inlet and outlet nozzles 1 to 6, compression plates 16 to 18, upper top plate 7, lower bottom plate 8, and the size between the top top plate and the bottom bottom plate is 3n+1 and The hexagonal heat transfer plates of the same shape are stacked in order to form a hexagonal columnar body at intervals, which are used as the heat exchange core 9. The edges of the adjacent heat transfer plates are hermetically connected, and a cavity is left in the middle of the adjacent heat transfer plates. As a fluid channel, a total of 3n layers of parallel fluid channels are formed from bottom to top; each of the three adjacent layers serves as a channel for the three media A, B, and C, on the three sets of relatively parallel side walls of the hexagonal column Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com