Double cooled ozone discharging tube

A discharge tube and ozone technology, applied in the field of discharge tubes, can solve the problems affecting the efficiency of the ozone generator, unable to set up a high-power system, unable to effectively conduct heat, etc., to achieve a simple structure, improved odor yield, and low unit power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

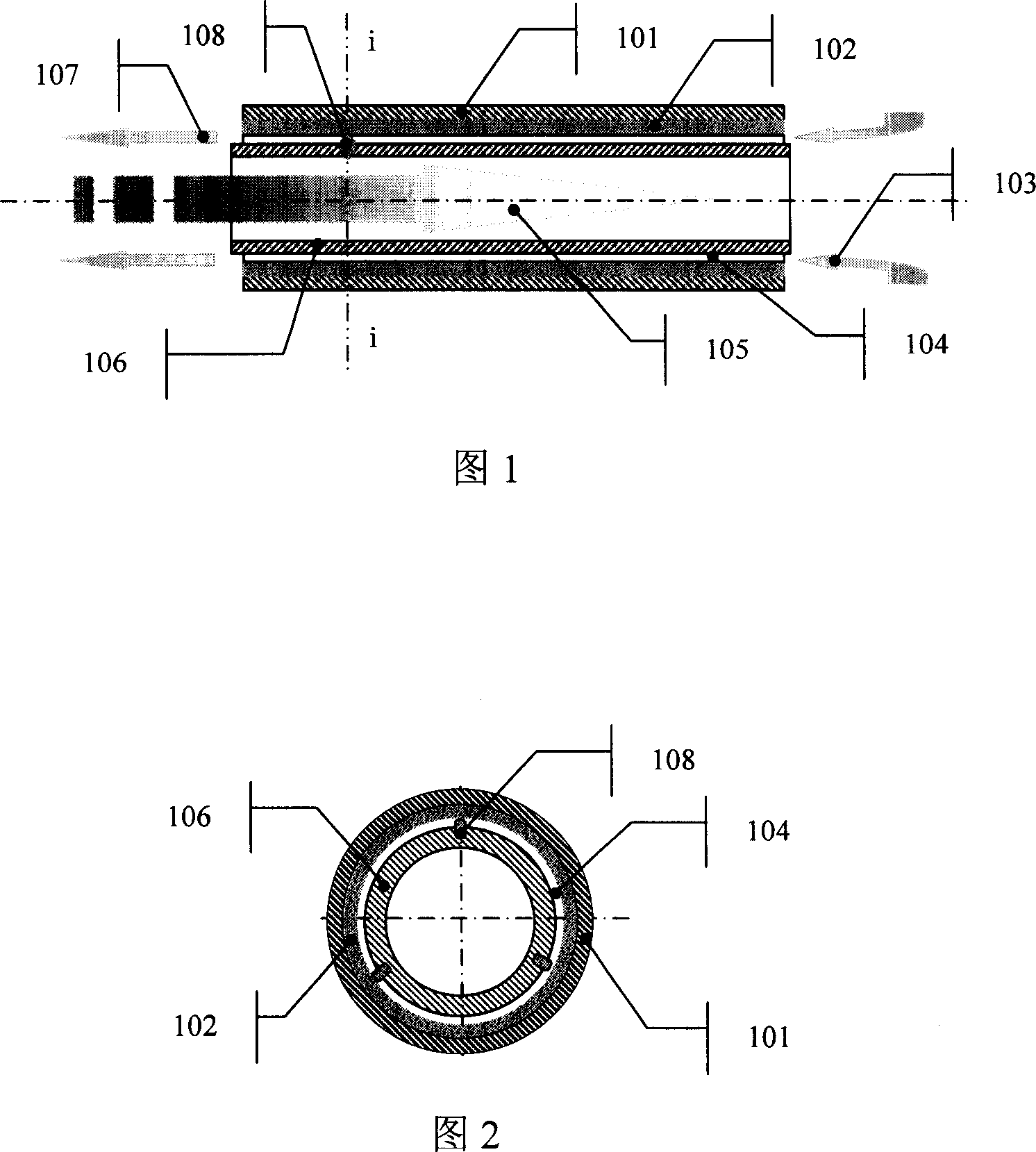

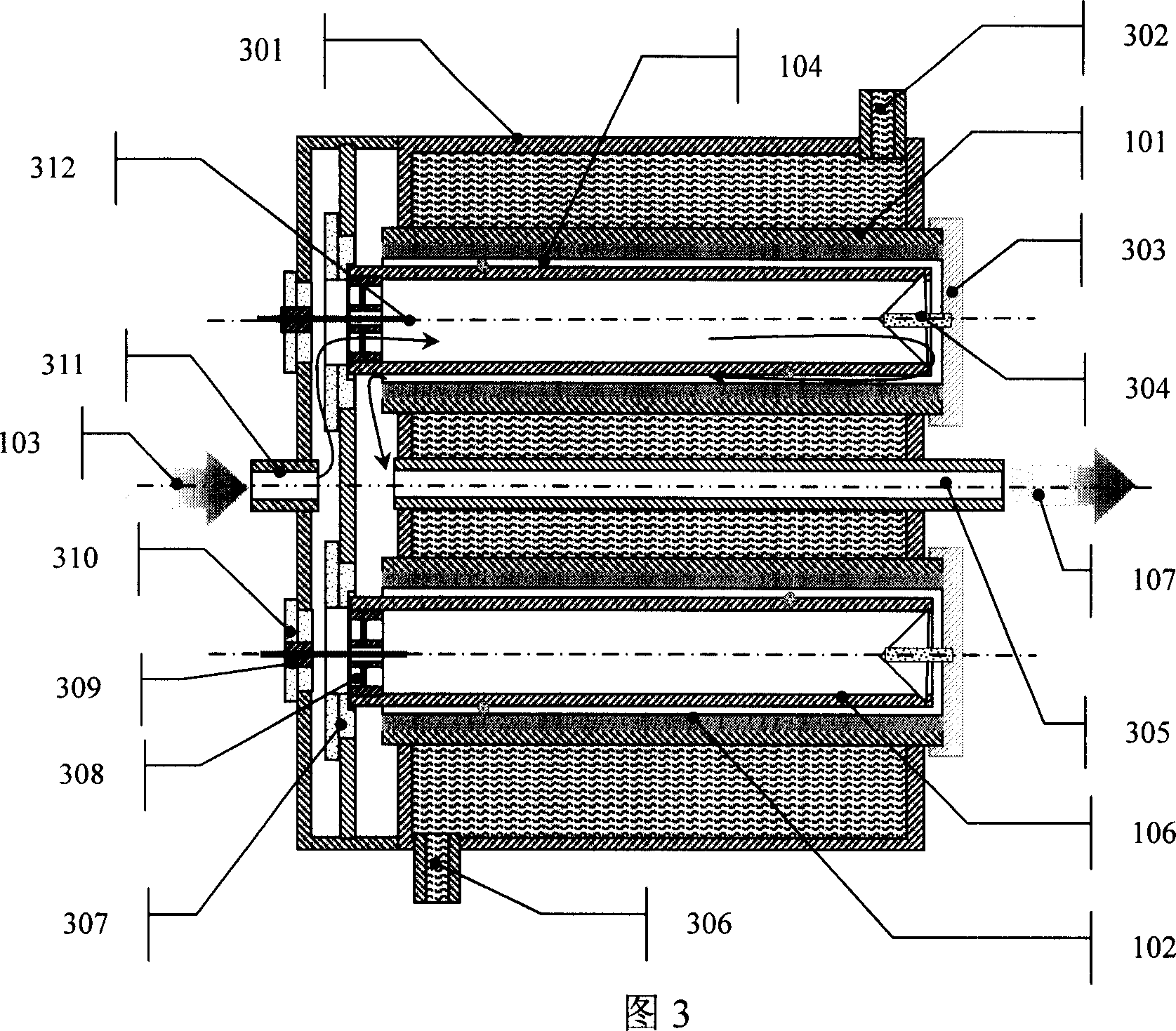

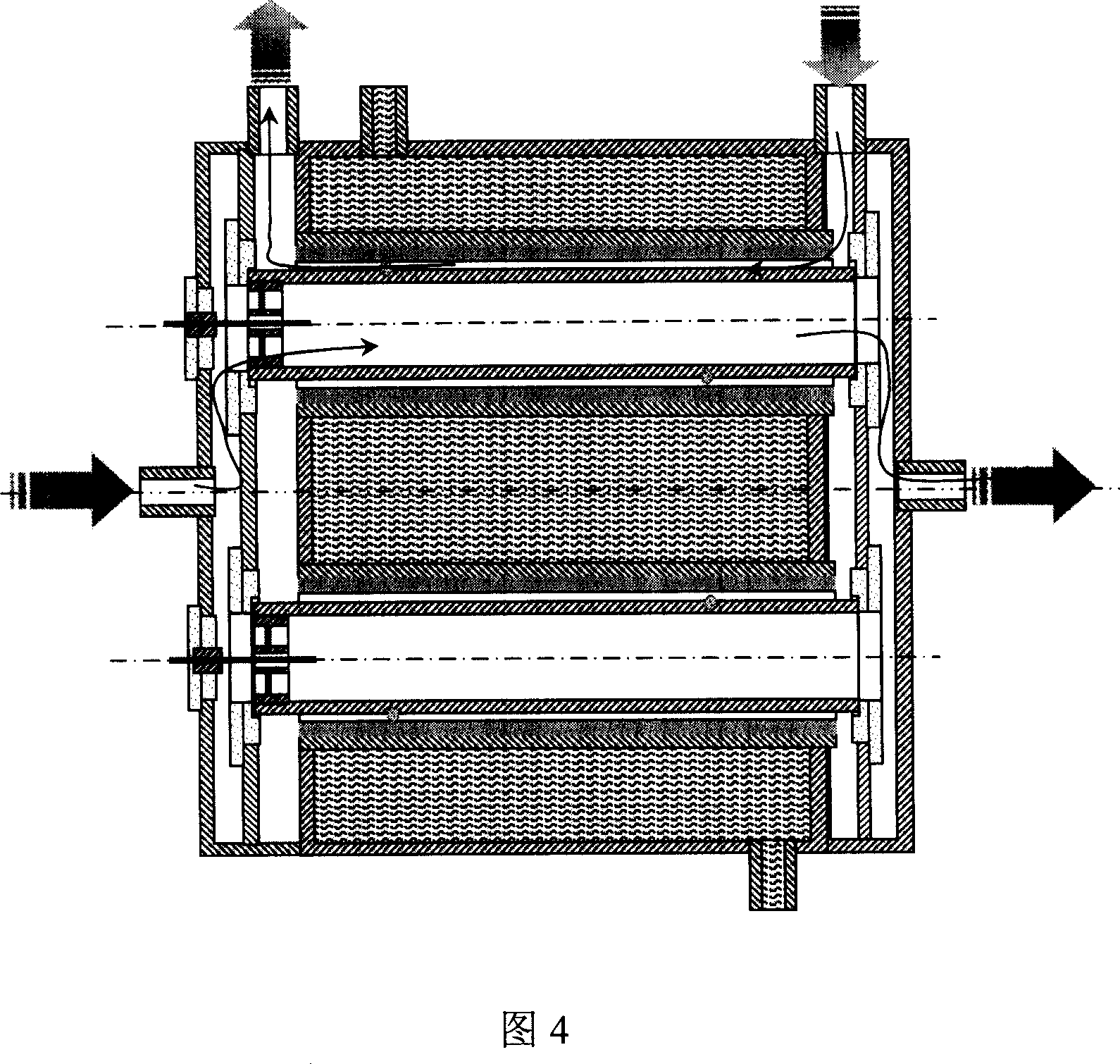

[0020] Referring to Fig. 1 and Fig. 2, the present invention includes a high-voltage electrode 106 and a ground electrode 101 made of metal tubes, and the surfaces of the high-voltage electrode 106 and the ground electrode 101 are plated with titanium or titanium alloy. The inner wall of the ground electrode 101 is lined with a dielectric layer 102 . The outer wall of the high-voltage electrode 106 is provided with a gap bump 108 supported by the dielectric layer 102 to form a sliding concentric circle, and an electric tube assembly with a discharge working air gap 104 . The thickness of the medium layer 102 is 0.3-1.5mm, and its material is one of ceramics, enamel, glaze, glass or a composite medium of several kinds. During use, the cooling gas 105 dissipates heat through the inner wall of the high-voltage electrode 106, the source gas 103 passes through the discharge working air gap 104 to form an ozone gas 107, and the ground electrode 101 is cooled by cooling water.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com