Polyphenyl foaming particle surface roughening machine

A polystyrene foaming and particle surface technology, which is applied in the manufacture of tools, grinding machines, metal processing equipment, etc., can solve the problems of poor bonding and small adhesion, and achieve the effect of enhanced adhesion, high connection strength, and uniform and dense materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

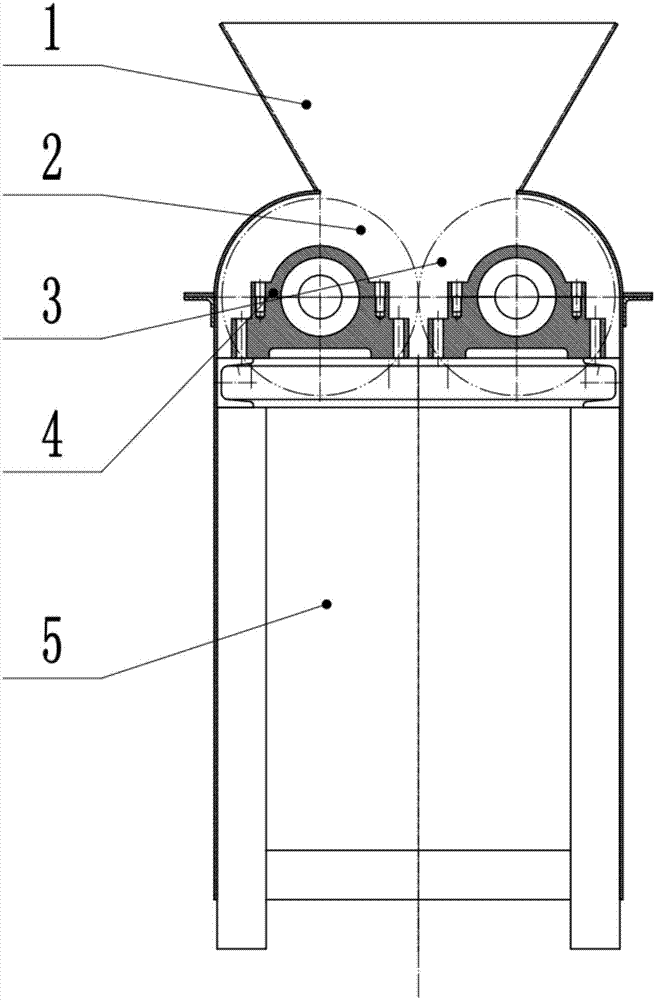

[0017] Such as figure 1 As shown, a surface roughening machine for polystyrene foamed particles adopts a double steel wire roller structure, including: feed inlet 1, driven steel wire roller 2, driving steel wire roller 3, bearing seat 4 and material box 5;

[0018] The feed inlet 1 is a funnel-shaped structure, the lower end of the feed inlet 1 is connected with the driven wire roller 2 and the driving wire roller 3, the driving wire roller 3 is used as the active operating mechanism, and the driving wire roller 3 is controlled by the electric device. The driving shaft rotates, the driven wire roller 2 is in a free state, the driven wire roller 2 and the driving wire roller 3 are placed side by side, the driven wire roller 2 and the driving wire roller 3 are in clearance fit, and the driven wire roller 2 and the driving wire roller 3 There are gaps through the foam particles;

[0019] The driven steel wire roller 2 and the driving steel wire roller 3 are installed on the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com