Fin-sleeve type three mediums composite heat-exchanger

A heat exchanger, casing type technology, applied in the direction of heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problem of inability to achieve synchronous heat exchange of three media, and achieve the effect of synchronous heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

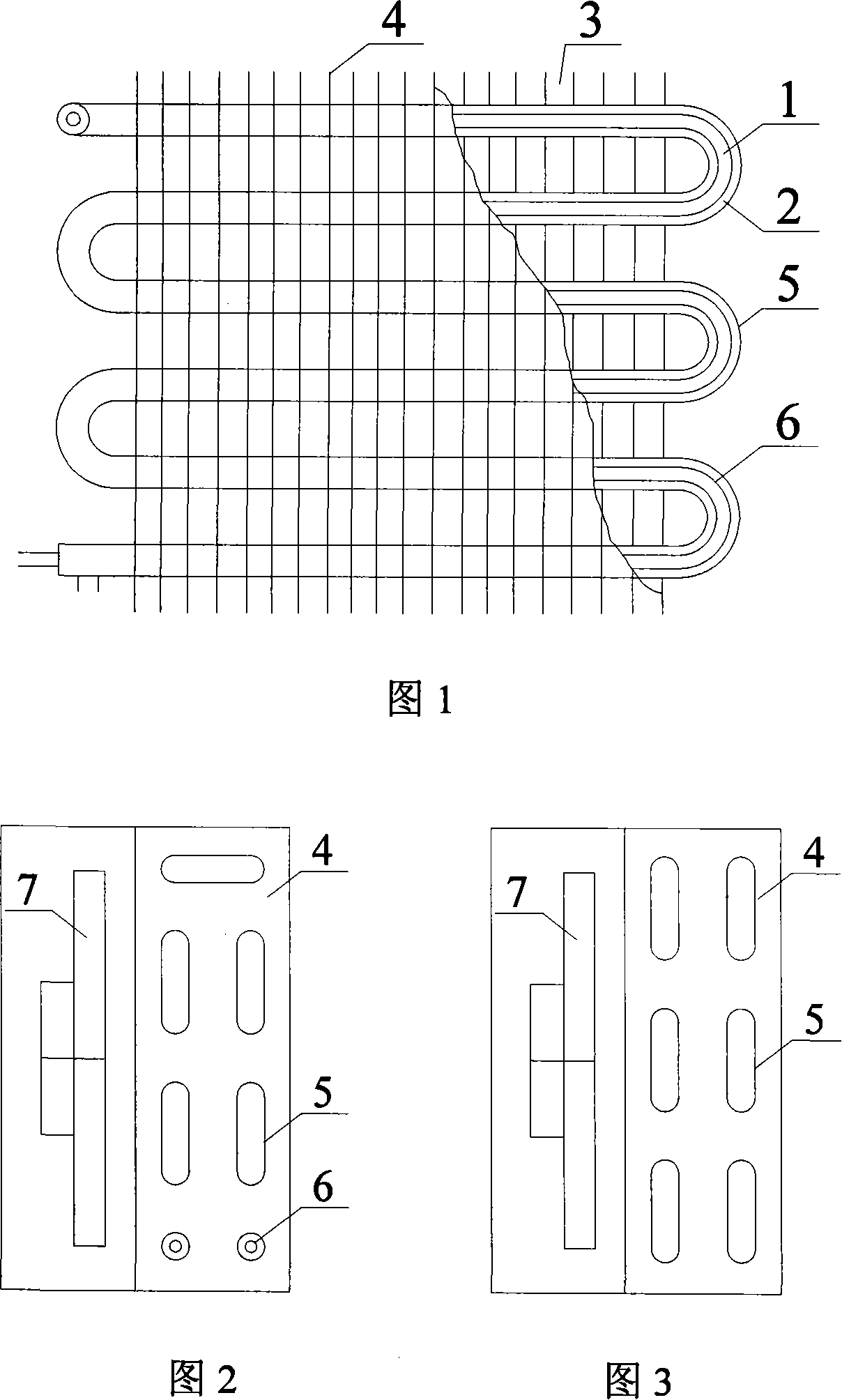

[0018] As shown in Fig. 1, Fig. 2 and Fig. 3, the fin-tube type three-medium composite heat exchanger of the present invention includes a shell, a fan 7 located in the shell and a heat exchanger body, and the heat exchanger body includes An outer casing 5 coiled in a serpentine (or S-shaped) shape, an inner casing 6 fitted in the lumen of the outer casing, and fins 4 combined with the outer wall of the outer casing; the outer diameter of the inner casing is smaller than that of the outer casing The aperture of the tube, and the liquid (or two-phase) medium channel 2 is formed by the annular space between the outer wall of the inner casing and the inner wall of the outer casing, the lumen of the inner casing forms the liquid (or two-phase) medium channel 1, and the fins and The outer surface of the outer casing constitutes a gaseous (or gas mixed with spray liquid) medium channel 3 . When exchanging heat with the medium in channel 3 alone, channel 1 is closed, fan 7 is turned o...

Embodiment 2

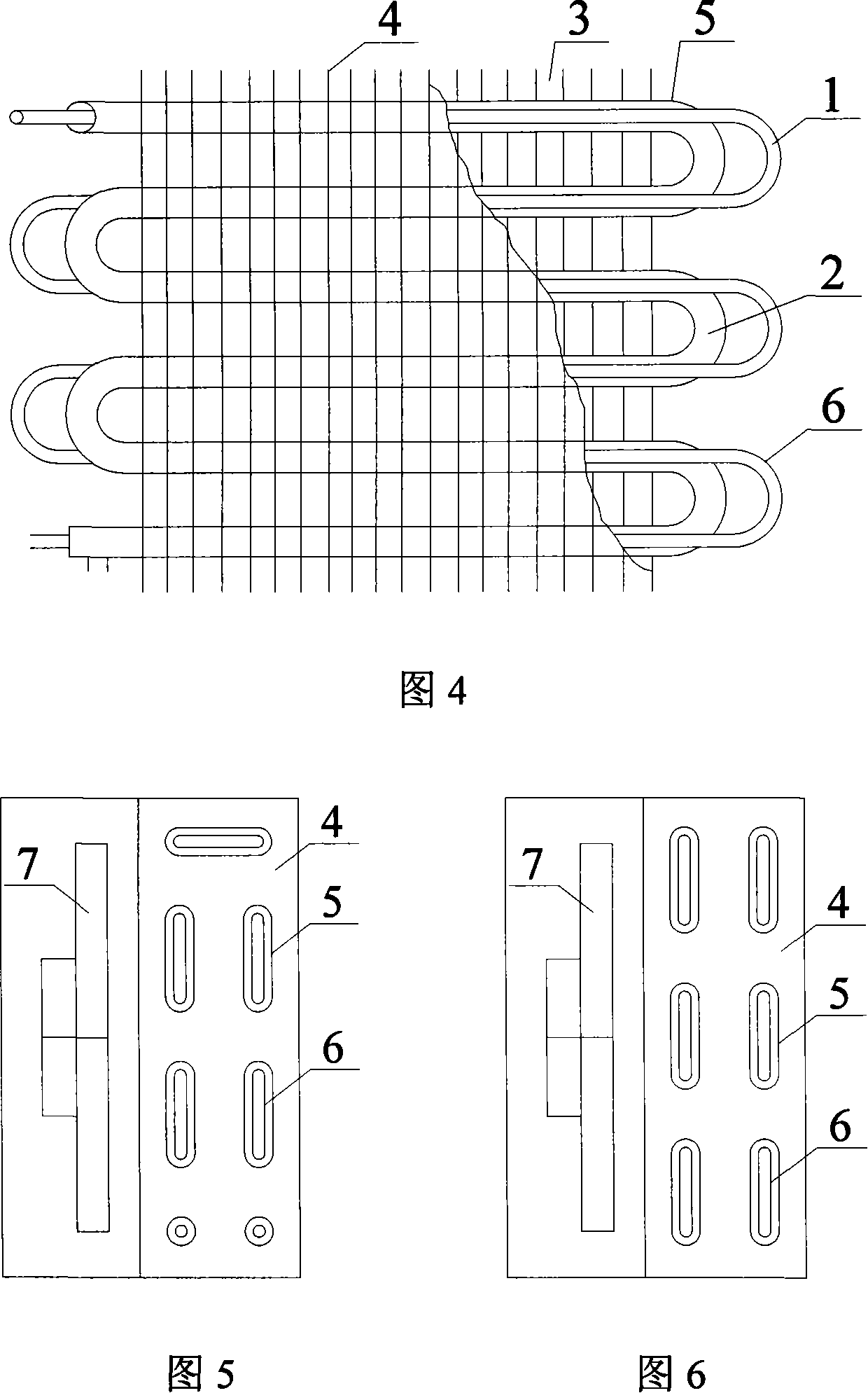

[0021] In order to simplify the processing technology and reduce the manufacturing cost, the fin-tube type three-medium composite heat exchanger of the present invention can be realized by adopting the structural methods shown in Fig. 4, Fig. 5 and Fig. 6: that is, the common At the bend, the ∩-shaped bent end of the inner sleeve passes through the pipe wall of the ∩-shaped bent end of the outer sleeve and is placed outside the ∩-shaped bent end of the outer sleeve. Its working principle and the structure of other parts are all the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com