CO2 emulsion and method for reforming and exploiting natural gas hydrate reservoir by injecting CO2 emulsion

A hydrate and CO2 technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of poor diffusivity, inability to effectively cover natural gas hydrate reservoirs, wellbore blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The volume fraction of distilled water in the emulsion is 50vol%, liquid CO 2 The volume fraction of is 50vol%, the mass fraction of surfactant AOT is 3wt%, the massfraction of Tween80 is 1wt%, the massfraction of tetrabutylammonium bromide (TBAB) is 0.1wt% (all based on water quantity calculation). The preparation temperature is 293.2K, the preparation pressure is 10MPa, and the stirring speed is 2000r / min. CO was generated under the condition of stirring for 3 hours 2 lotion. CO 2 When the emulsion is injected above the hydrate reservoir, the reservoir conditions are: temperature 278.2K, pressure 8MPa, methane hydrate saturation 29.29.

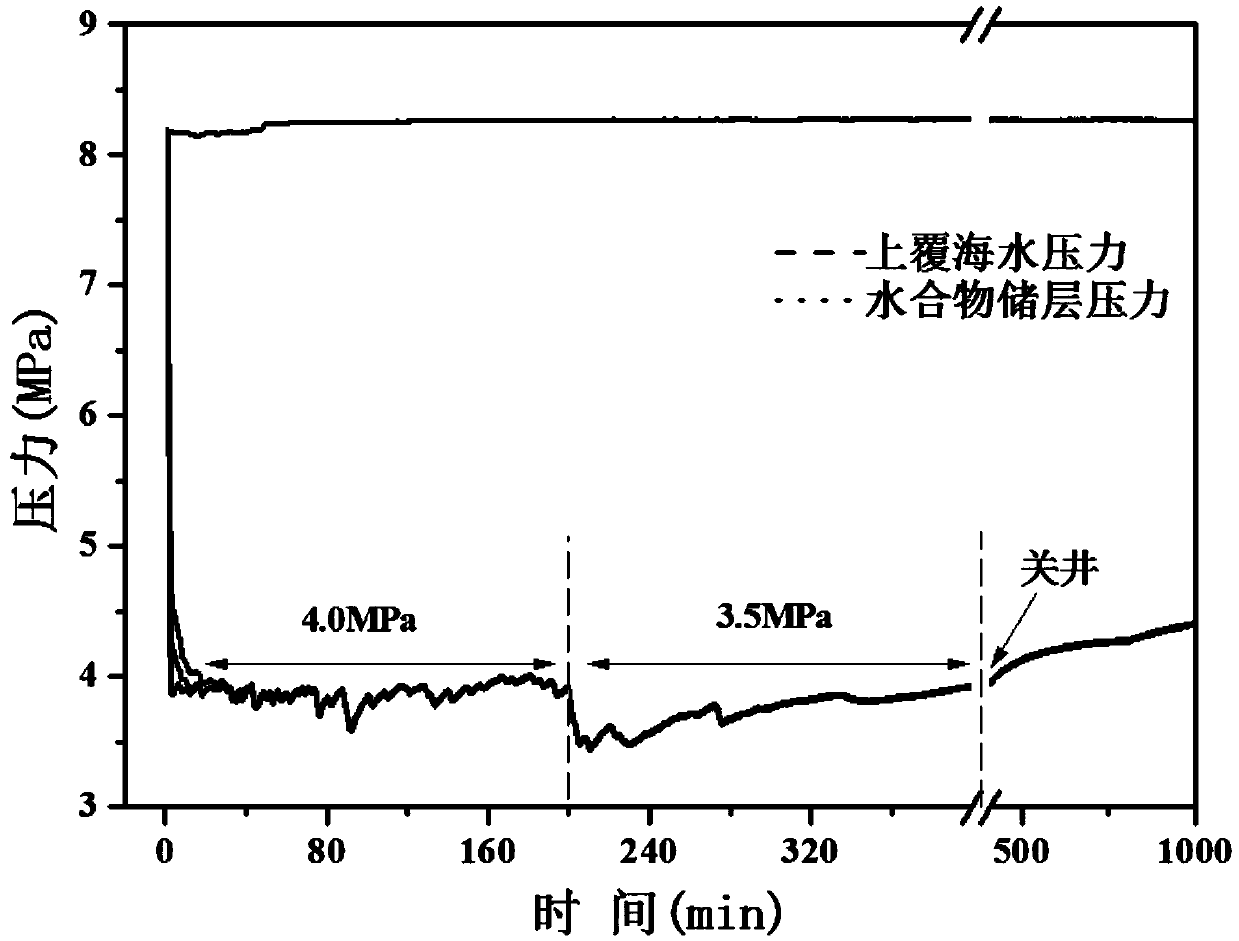

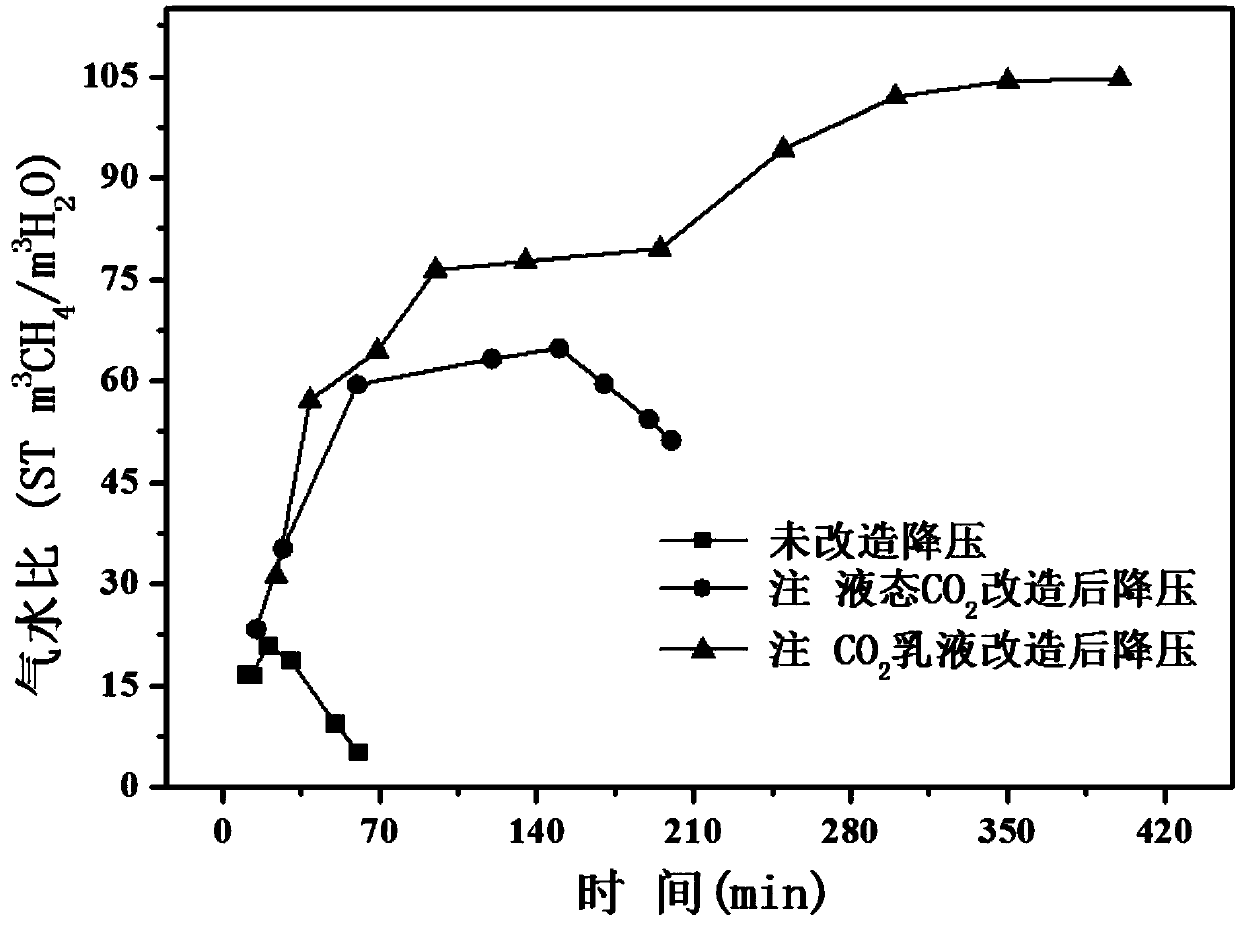

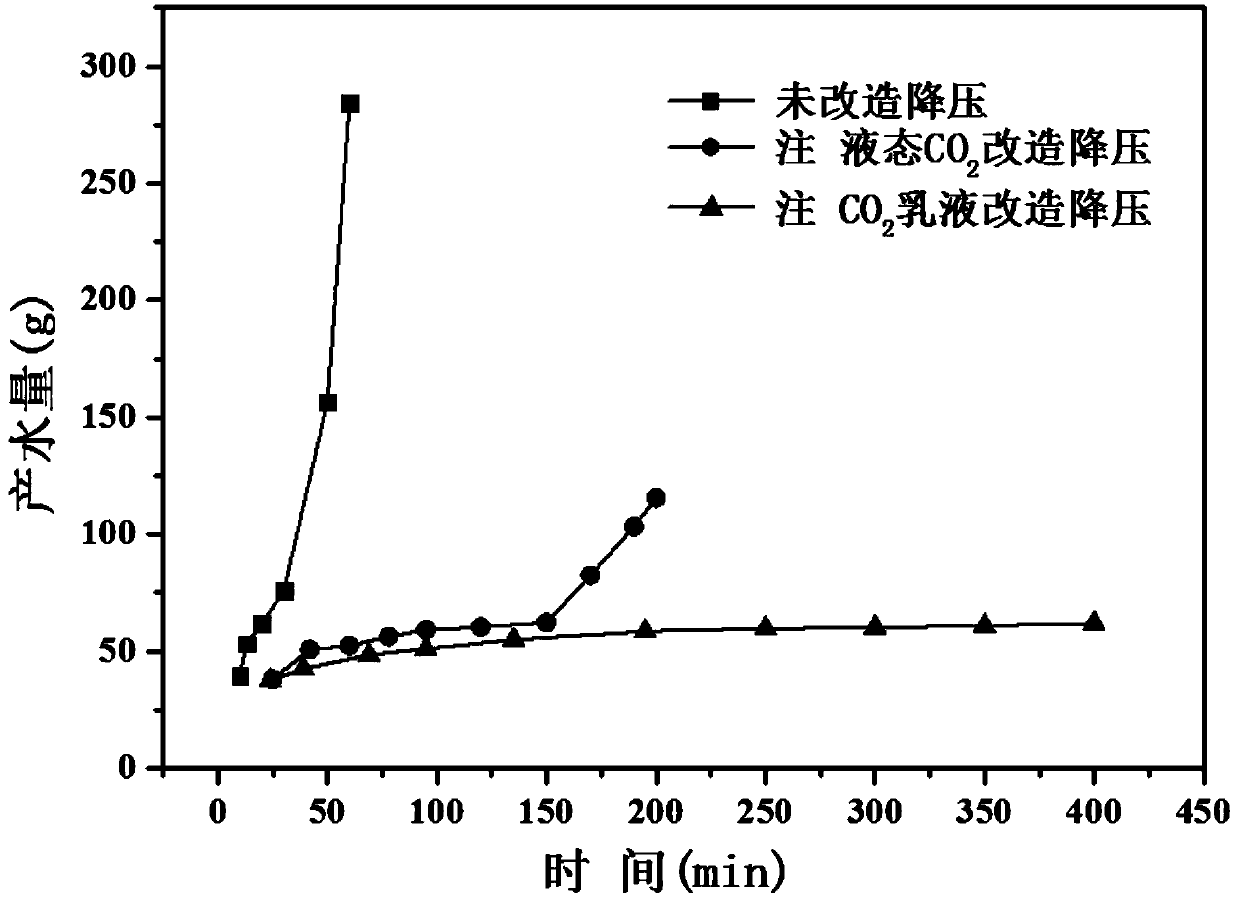

[0038] The emulsion construction method of this embodiment is to prepare CO2 under high temperature and high pressure conditions. 2 Emulsion, and inject the emulsion above the gas hydrate reservoir under the condition higher than the reservoir pressure to form CO 2 Hydrate cover. When CO 2 After the emulsion is converted into h...

Embodiment 2

[0040] In order to study the utilization of CO provided by the present invention 2 The effect of emulsion reformation on natural gas hydrate reservoirs and exploitation, the present invention uses a one-dimensional visualized hydrate simulation device to carry out corresponding simulation experiments. The reactor is composed of three sapphire tubes and four stainless steel tubes, with a height of 1m, an effective volume of 0.51L, and a uniform inner diameter of 2.54cm. The maximum operating pressure of the reactor is 32MPa, and four pressure sensors and temperature sensors are inserted in different positions in the reactor to measure the pressure and temperature changes in the reactor during the experiment. The specific steps are as follows: First, accurately weigh a certain amount of sand and 3.35% salt water and fully and uniformly mix the two. The sand-water mixture is then charged into the reactor. Accurately weigh a certain amount of seabed sediment, put it into the ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com