Treatment process and treatment system for municipal sludge

A municipal sludge and disposal system technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve direct incineration, difficult sludge large-scale disposal, impact Cement clinker production and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings of the present invention.

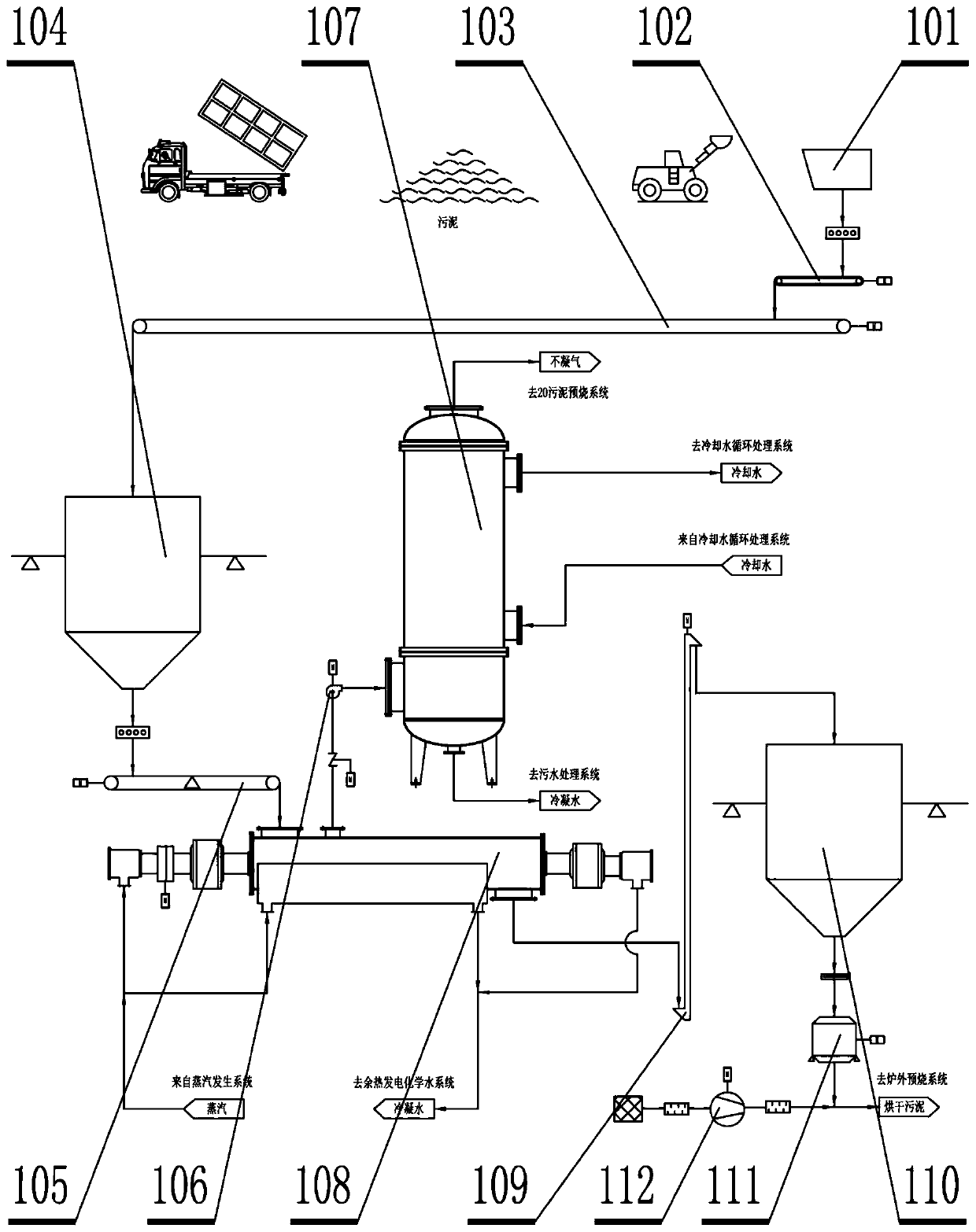

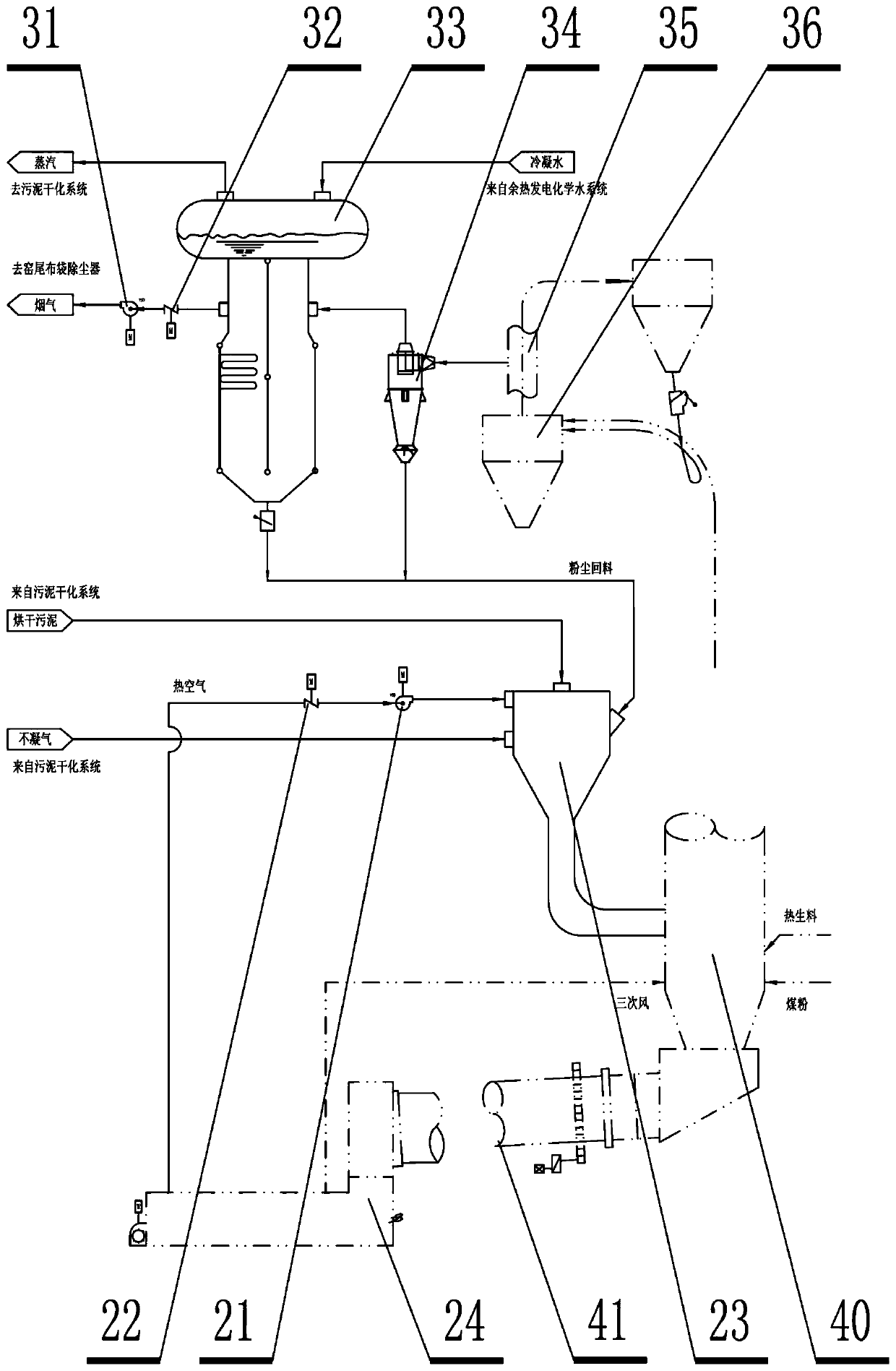

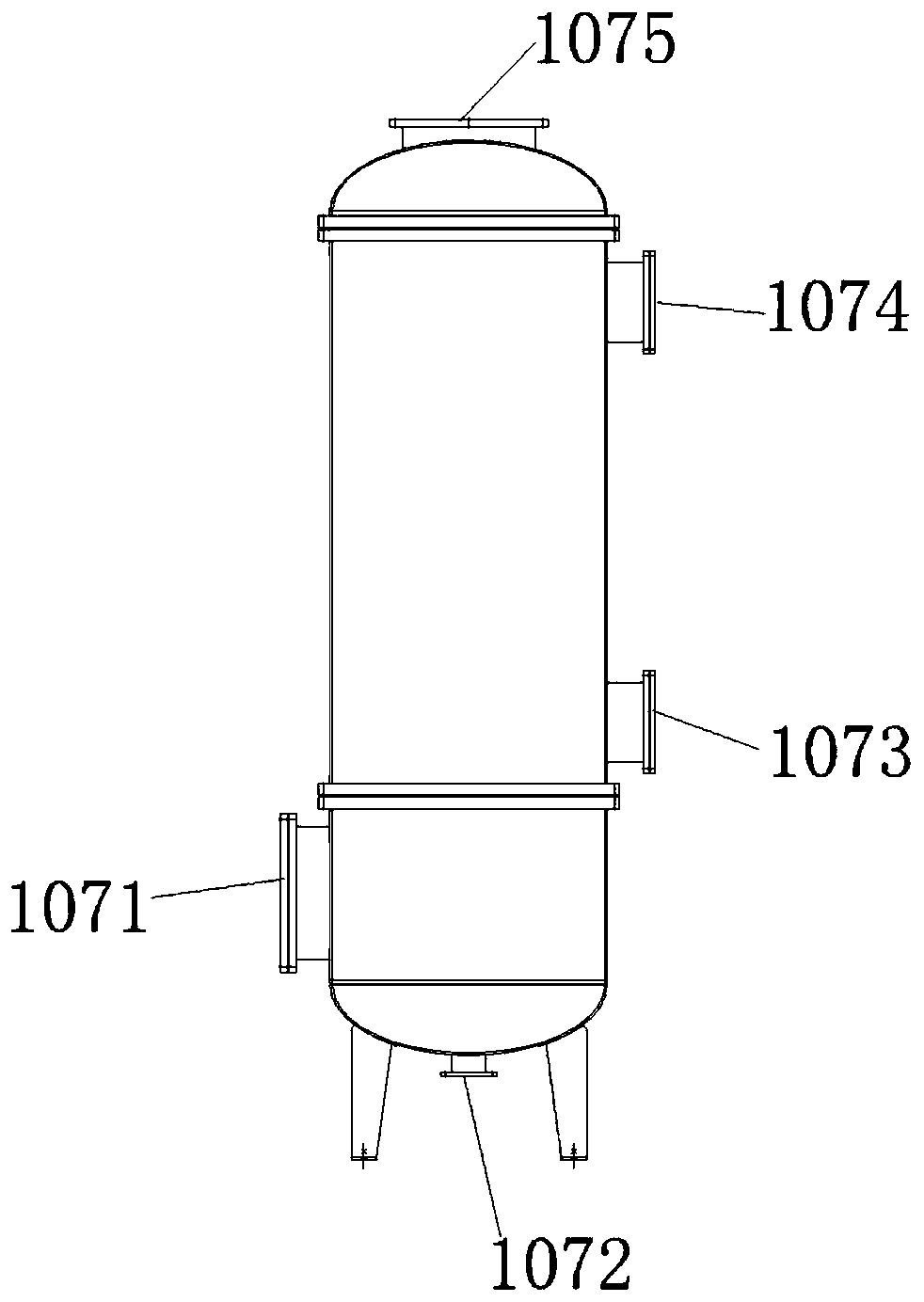

[0046] Please refer to Figure 1-7 , the present invention provides a treatment system for municipal sludge, which is located outside the calciner 40 and connected with the calciner 40 and cement plant equipment, including a sludge drying system 10, a pre-burning system outside the furnace 20 and a steam generation system 30, the steam generation system 30 is connected to the sludge drying system 10, the external pre-burning system 20 is connected to the sludge drying system 10 and the steam generation system 30 respectively, and the cement plant equipment includes There are cooling water circulation treatment system, sewage treatment system, waste heat power generation chemical water system, kiln tail bag filter and cement clinker production line flue gas treatment system, etc.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com