Black cerium dioxide nano-material and preparation method thereof

A technology of cerium oxide and nanomaterials, applied in the direction of cerium oxide/cerium hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of organic ligands that are not resistant to high temperature, expensive, high energy consumption, etc., and achieve excellent photothermal The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] According to a typical implementation of the present invention, an embodiment of the present invention provides a method for preparing a black ceria nanomaterial, comprising:

[0035] S1. Mix and stir the cerium salt solution and the lye to carry out the first reaction to obtain a precipitate; the molar concentration ratio of the cerium salt solution to the lye is 1:100-200;

[0036] Cerium salt solution reacts with alkali such as sodium hydroxide to generate cerium hydroxide;

[0037] If the molar concentration ratio of cerium salt to alkali is too low, black cerium oxide cannot be finally produced, and if the molar concentration ratio is too high, there will be problems of sodium hydroxide dissolution and subsequent cleaning of surface alkali salt is difficult.

[0038] S2. placing the precipitate in liquid nitrogen for low-temperature treatment to obtain blue crystals;

[0039] S3. Thawing and drying the blue crystals to obtain yellow cerium oxide;

[0040] This pr...

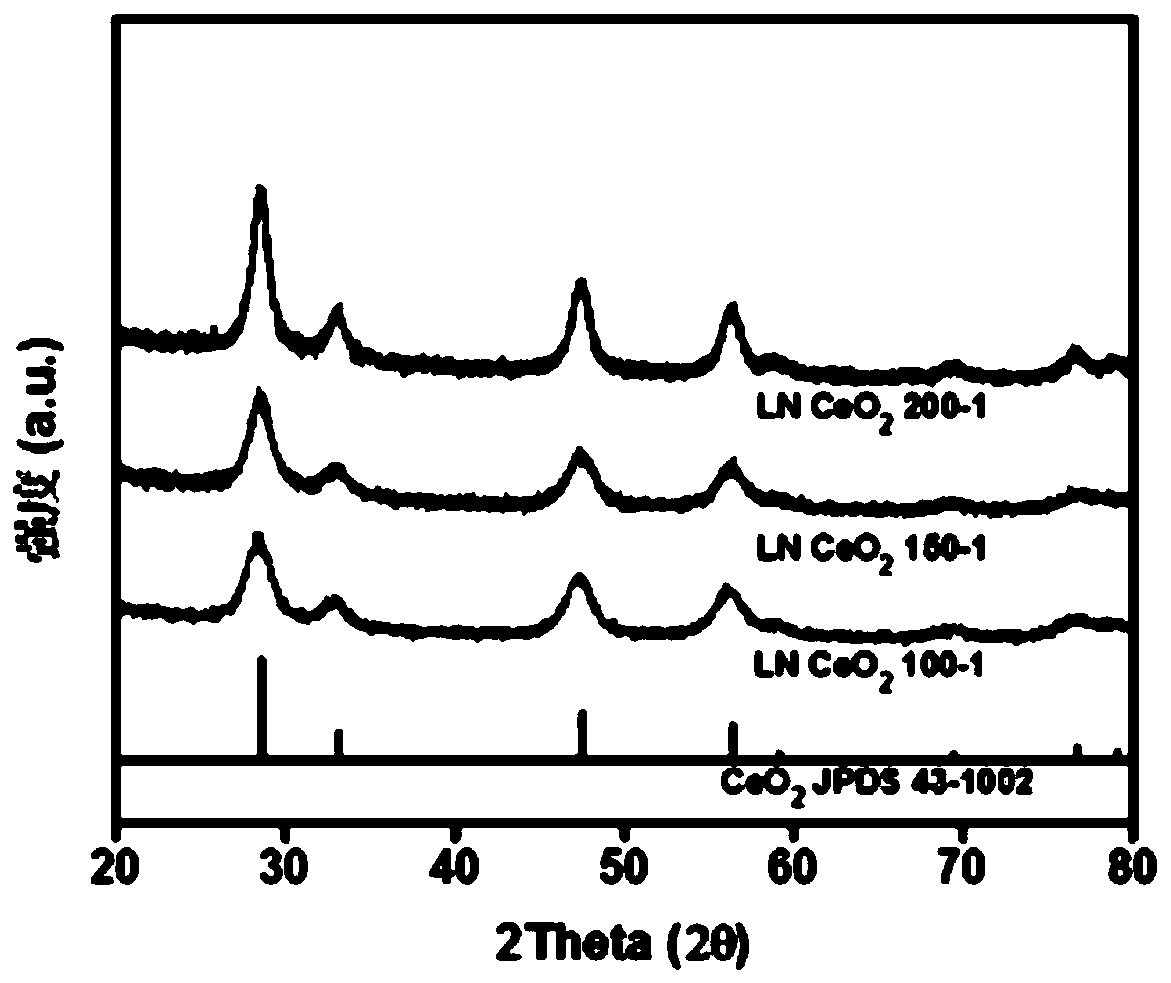

Embodiment 1

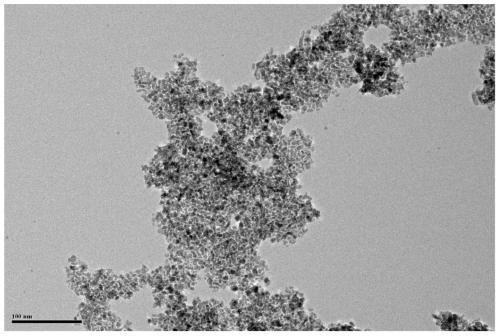

[0061] Dissolve 1.96g of persimmon nitrate hexahydrate in 40ml of deionized water, 18.1g of NaOH in 30ml of deionized water, add the cerium salt solution dropwise into the sodium hydroxide solution, stir evenly in the beaker at 400rpm for 30min, the mixed solution appears light blue Add the mixed solution dropwise into 500ml liquid nitrogen to obtain a light blue solid, wash it with deionized water after thawing, then centrifuge at 6000rpm, repeat the washing and centrifugation for 5 times, and dry it in an oven at 80°C for 24h to obtain a yellow cerium oxide nano material, denoted as LNCeO 2 100-1, reduced at a temperature of 500 ° C to obtain the desired black ceria nanomaterial product.

Embodiment 2

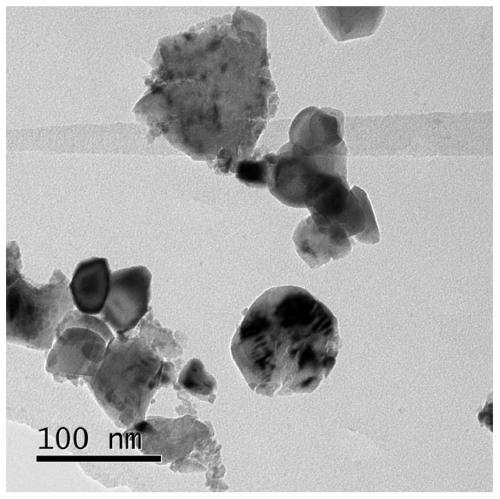

[0063] Dissolve 1.96g of cerium nitrate hexahydrate in 40ml of deionized water, 27.15g of NaOH in 30ml of deionized water, add the cerium salt solution dropwise into the sodium hydroxide solution, stir evenly in a beaker at 400rpm for 30min, the mixed solution appears light blue Add the mixed solution dropwise into 500ml liquid nitrogen to obtain a light blue solid, wash it with deionized water after thawing, then centrifuge at 6000rpm, repeat the washing and centrifugation for 5 times, and dry it in an oven at 80°C for 24h to obtain a yellow cerium oxide nano material, denoted as LNCeO 2 150-1, reduced at a temperature of 500°C to obtain the desired black ceria nanomaterial product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com