Preparation method of superfine cobalt-nickel powder for hard alloys

A cemented carbide, cobalt-nickel technology, applied in the field of preparation of ultra-fine cobalt-nickel powder, can solve problems such as cobalt powder agglomeration, powder mixing inhomogeneity, cemented carbide hole defects, etc., to provide service life, uniform particle size distribution, Avoid the effect of powder agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

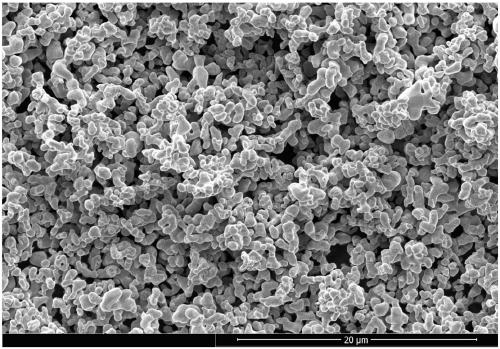

Image

Examples

Embodiment 1

[0030] Embodiment 1 of the present invention provides a kind of preparation method that is used for the superfine cobalt-nickel powder of cemented carbide, and its method is implemented through the following steps:

[0031] Step 1, mix the cobalt chloride solution with a concentration of 60-80g / L and the nickel chloride solution with a concentration of 120-140g / L to form a bottom solution in a metal molar ratio of 1:1.5, and add the bottom solution to the reaction In the kettle, the amount of bottom liquid added is 2~3m 3 , after that, add a sodium carbonate solution with a concentration of 120 to 150 g / L into the reaction kettle by spraying, the mass ratio of the added sodium carbonate solution to the bottom liquid is 1:1.5, and the reaction kettle is kept warm to 40°C Stir for 4h to obtain a cobalt-nickel mixed solution;

[0032] Step 2, transfer the cobalt-nickel composite solution obtained in step 1 into a filter press to remove the mother liquor, wash with pure water at ...

Embodiment 2

[0037] Embodiment 2 of the present invention provides a kind of preparation method that is used for the superfine cobalt-nickel powder of cemented carbide, and its method is implemented through the following steps:

[0038] Step 1, mix the cobalt chloride solution with a concentration of 60-80g / L and the nickel chloride solution with a concentration of 120-140g / L to form a bottom solution in a metal molar ratio of 1:1.4, and add the bottom solution to the reaction In the kettle, the amount of bottom liquid added is 2~3m 3 , after that, add a sodium carbonate solution with a concentration of 120 to 150 g / L into the reactor by spraying, the mass ratio of the added sodium carbonate solution to the bottom liquid is 1:1.4, and the reactor is kept warm to 60°C Stir for 3.8h to obtain a cobalt-nickel mixed solution;

[0039] Step 2, transfer the cobalt-nickel composite solution obtained in step 1 into a filter press to remove the mother liquor, wash with pure water at 72°C for 3 to ...

Embodiment 3

[0044] Embodiment 3 of the present invention provides a kind of preparation method that is used for the superfine cobalt-nickel powder of cemented carbide, and its method is implemented through the following steps:

[0045] Step 1, mix the cobalt chloride solution with a concentration of 60-80g / L and the nickel chloride solution with a concentration of 120-140g / L to form a bottom solution according to the metal molar ratio of 1:1:3, and add the bottom solution Into the reaction kettle, the amount of bottom liquid added is 2~3m 3 , after that, add a sodium carbonate solution with a concentration of 120 to 150 g / L into the reactor by spraying, the mass ratio of the added sodium carbonate solution to the bottom liquid is 1:1.3, and the reactor is kept warm to 80°C Stir for 3h to obtain a cobalt-nickel mixed solution;

[0046]Step 2, transfer the cobalt-nickel composite solution obtained in step 1 into a filter press to remove the mother liquor, wash with pure water at 72°C for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com