Preparation method of mineralized flat filament sewage treatment membrane

A technology for sewage treatment and flat silk, which is applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of limiting the application of nano-hydroxyapatite materials and lack of adsorption materials, etc. Achieve the effect of excellent heavy metal and organic solvent adsorption performance, good stability and excellent structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps in turn:

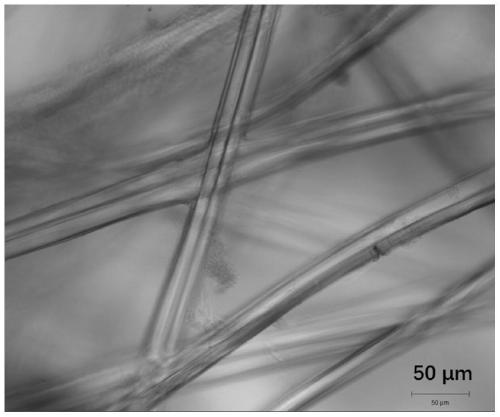

[0033] (1) The large silkworms in the silk-spinning stage spin silk in a flat object to obtain flat silk, and the microscopic appearance is a micron-scale fiber structure (such as figure 1 shown);

[0034] (2) Fix the flat wire in step (1) around, clean it up, keep it in deionized water with a water temperature of 40°C for 30min, and degumming;

[0035] (3) Soak the degummed flat silk in step (2) in 2% urea solution for 30min, so that the crystal structure in the flat silk is softened; Soak and wash several times with 80% ethanol solution afterwards, make the flat silk in the flat silk The fibroin is solidified to obtain post-treated flat silk;

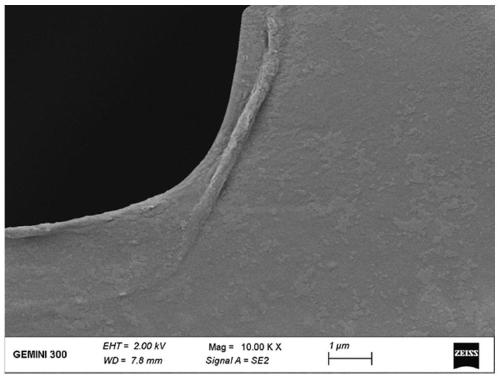

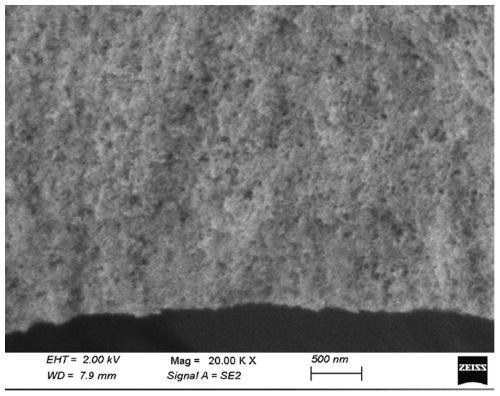

[0036] (4) Adding the post-treated flat wire material in step (3) into the mineralization solution for biomimetic mineralization. The steps of biomimetic mineralization are as follows: put CaCl 2 (final concentration 100mM) join in the flat silk material of aftertreatm...

Embodiment 2

[0038] This embodiment includes the following steps in turn:

[0039] (1) The large silkworm in the silk-spinning stage spins silk in a plane object to obtain flat silk;

[0040] (2) Fix the four sides of the flat wire in step (1), clean it up, keep it in deionized water with a water temperature of 60° C. for 20 minutes, and degumming;

[0041] (3) Soak the degummed flat silk in step (2) with 1% urea solution and wash several times, so that the fibroin in the flat silk is solidified, and obtain post-treated flat silk;

[0042] (4) Adding the post-treated flat wire material in step (3) into the mineralization solution for biomimetic mineralization. The steps of biomimetic mineralization are as follows: put Ca(NO 3 ) 2 4H 2 O (final concentration 10mM) was added to the post-treated flat silk material and soaked for 1h; the final concentration was 6mM (NH 4 ) 2 HPO 4Slowly drop it into the composite solution at a rate of 2mL / min. During this period, the solution system is ...

Embodiment 3

[0045] This embodiment includes the following steps in turn:

[0046] (1) The large silkworm in the silk-spinning stage spins silk in a plane object to obtain flat silk;

[0047] (2) Fix the flat wire in step (1) around, clean it up, keep it in deionized water with a water temperature of 80°C for 20min, and carry out degumming;

[0048] (3) Soak the degummed flat silk in step (2) in 10% urea solution for 20min, so that the crystal structure in the flat silk is softened; then soak and wash several times with 80% methanol solution, so that the flat silk in the flat silk The fibroin is solidified to obtain post-treated flat silk;

[0049] (4) Adding the post-treated flat wire material in step (3) into the mineralization solution for biomimetic mineralization. The steps of biomimetic mineralization are as follows: add CaCl2 (final concentration 20mM) to the post-treated flat silk material and soak for 1h; 2 HPO 4 Slowly drop it into the composite solution at a rate of 5mL / min....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com