Water passing pipe for precast concrete and preparation method thereof

A technology of prefabricated concrete and reinforced concrete pipes, applied in the field of concrete, can solve the problems of crack formation, concrete temperature rise rate, concrete structure cracking, etc., to achieve the effect of preventing temperature cracks, good promotion value, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

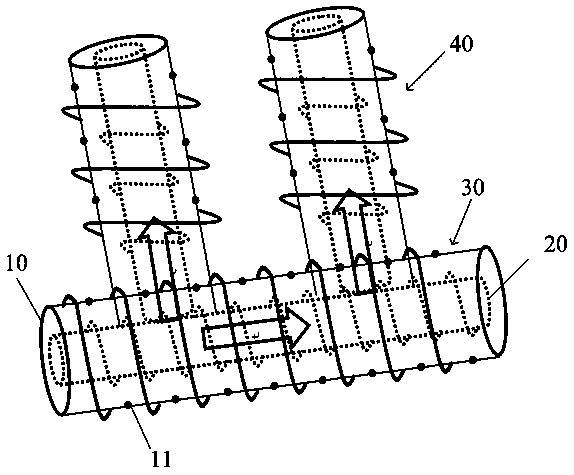

[0035] Combine below figure 1 , detailing the structural composition of the prefabricated concrete water pipe of the present invention.

[0036] Please refer to figure 1, a prefabricated concrete water pipe for controlling the internal temperature of mass concrete. The pipe part 40 and the horizontal pipe part 30 form a three-way connection. Both the horizontal pipe part 30 and the vertical pipe part 40 include an inner sleeve 20 and an outer sleeve 10 arranged in sequence from the inside to the outside. The inner sleeve 20 is a hollow plastic bellows , the outer casing 10 is a threaded reinforced concrete pipe formed by pouring steel bars, steel mesh sheets and concrete, and the steel bars and steel mesh sheets at the interface between the horizontal pipe part 30 and the vertical pipe part 40 are connected by spot welding, and poured precast concrete is connected An integral structure, the outer surface of the outer sleeve 10 is chiseled.

[0037] Specifically, this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com