A kind of polyethylene glycol-polycaprolactone phase change fiber and preparation method thereof

A polycaprolactone, polyethylene glycol technology, applied in fiber processing, chemical instruments and methods, conjugated synthetic polymer rayon, etc., can solve the limitation of polyethylene glycol application, difficult polyethylene glycol Effective coating and other issues, to achieve the effect of large latent heat of phase transition, excellent thermal and mechanical properties, and avoidance of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

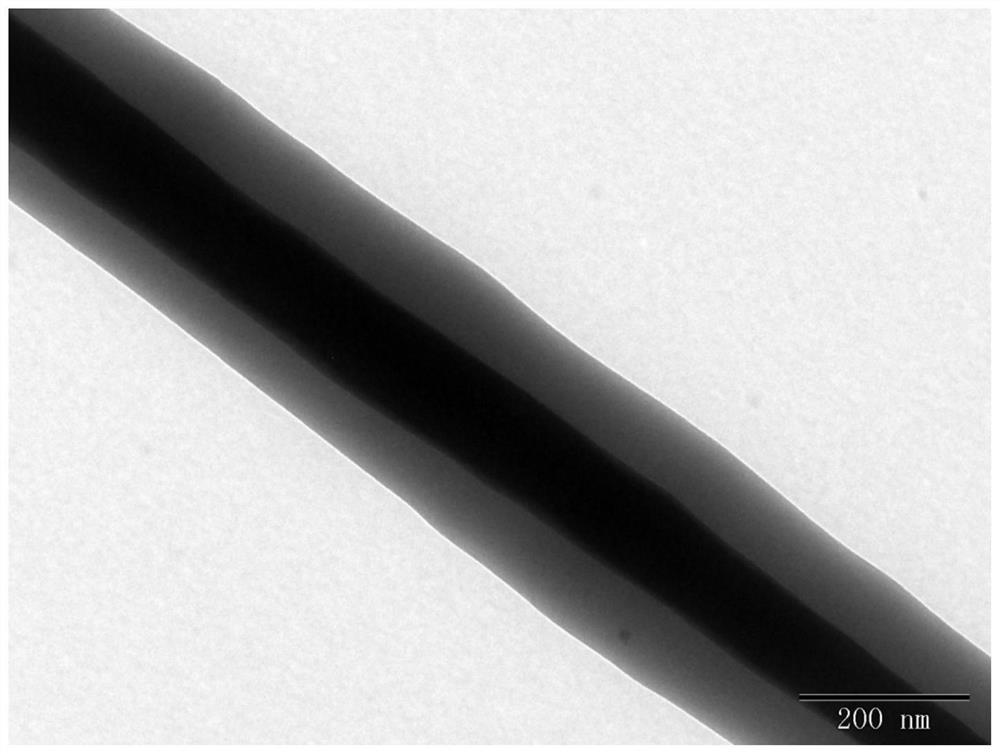

Image

Examples

Embodiment 1

[0033] (1) Add polyethylene glycol (with a weight average molecular weight of 1000) into a mixed solvent of N,N-dimethylformamide and dichloromethane (v / v=1 / 1) and magnetically stir at room temperature until completely dissolved, Ultrasound for 20 minutes to obtain polyethylene glycol spinning solution, the mass concentration of polyethylene glycol is 30%;

[0034] (2) Add polycaprolactone (weight-average molecular weight: 80,000) into a mixed solvent of N,N-dimethylformamide and dichloromethane (v / v=3 / 7) and magnetically stir at room temperature until completely dissolved, Obtain polycaprolactone spinning solution, the mass concentration of polycaprolactone in the shell solution is 10%;

[0035] (3) Take the polyethylene glycol spinning solution as the inner tube spinning solution and the polycaprolactone spinning solution as the outer tube spinning solution, place them in syringes respectively, and fix them on the syringe pump; use an inner diameter of 0.5mm , a coaxial spi...

Embodiment 2

[0039] (1) Add polyethylene glycol (with a weight average molecular weight of 1000) into a mixed solvent of N,N-dimethylformamide and dichloromethane (v / v=1 / 1) and magnetically stir at room temperature until completely dissolved, Ultrasound for 20 minutes to obtain polyethylene glycol spinning solution, the mass concentration of polyethylene glycol is 50%;

[0040] (2) Add polycaprolactone (weight-average molecular weight: 80,000) into a mixed solvent of N,N-dimethylformamide and dichloromethane (v / v=3 / 7) and magnetically stir at room temperature until completely dissolved, Obtain polycaprolactone spinning solution, the mass concentration of polycaprolactone is 10%;

[0041](3) Take the polyethylene glycol spinning solution as the inner tube spinning solution and the polycaprolactone spinning solution as the outer tube spinning solution, place them in syringes respectively, and fix them on the syringe pump; use an inner diameter of 0.5mm , a coaxial spinning needle with an ou...

Embodiment 3

[0045] (1) Add polyethylene glycol (with a weight average molecular weight of 1000) into a mixed solvent of N,N-dimethylformamide and dichloromethane (v / v=1 / 1) and magnetically stir at room temperature until completely dissolved, Ultrasound for 20 minutes to obtain polyethylene glycol spinning solution, the mass concentration of polyethylene glycol is 70%;

[0046] (2) Add polycaprolactone (weight-average molecular weight: 80,000) into a mixed solvent of N,N-dimethylformamide and dichloromethane (v / v=3 / 7) and magnetically stir at room temperature until completely dissolved, Obtain polycaprolactone spinning solution, the mass concentration of polycaprolactone is 10%;

[0047] (3) Take the polyethylene glycol spinning solution as the inner tube spinning solution and the polycaprolactone spinning solution as the outer tube spinning solution, place them in syringes respectively, and fix them on the syringe pump; use an inner diameter of 0.5mm , a coaxial spinning needle with an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com