Hard carbon graphite composite negative electrode material preparation method

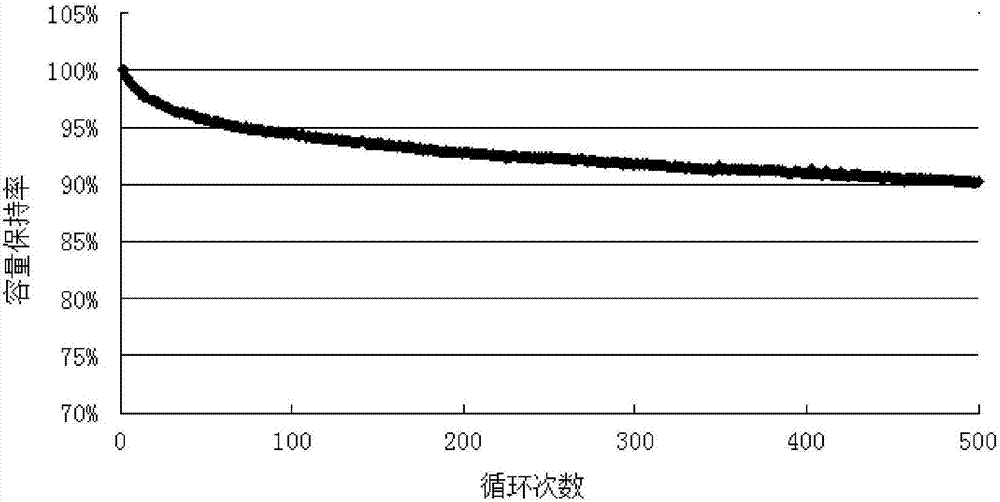

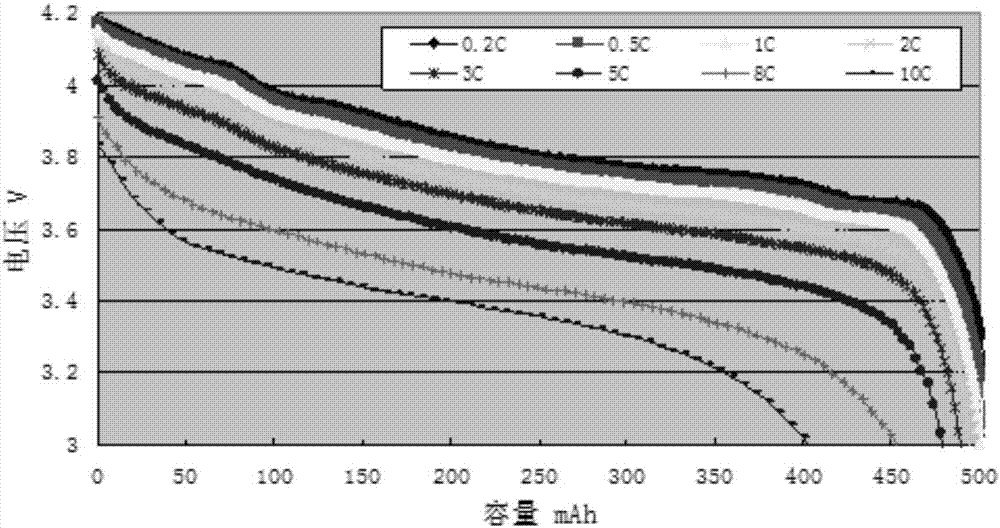

A technology of negative electrode material and graphite, applied in the field of preparation of hard carbon graphite composite negative electrode material, can solve the problem of poor rate performance of graphite negative electrode material, and achieve the effects of excellent comprehensive performance, good adaptability and good cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1. Weigh 100g of bisphenol A and weigh 400ml of NaOH solution with a mass concentration of 6%, mix and stir at 50°C for 10-15min until dissolved;

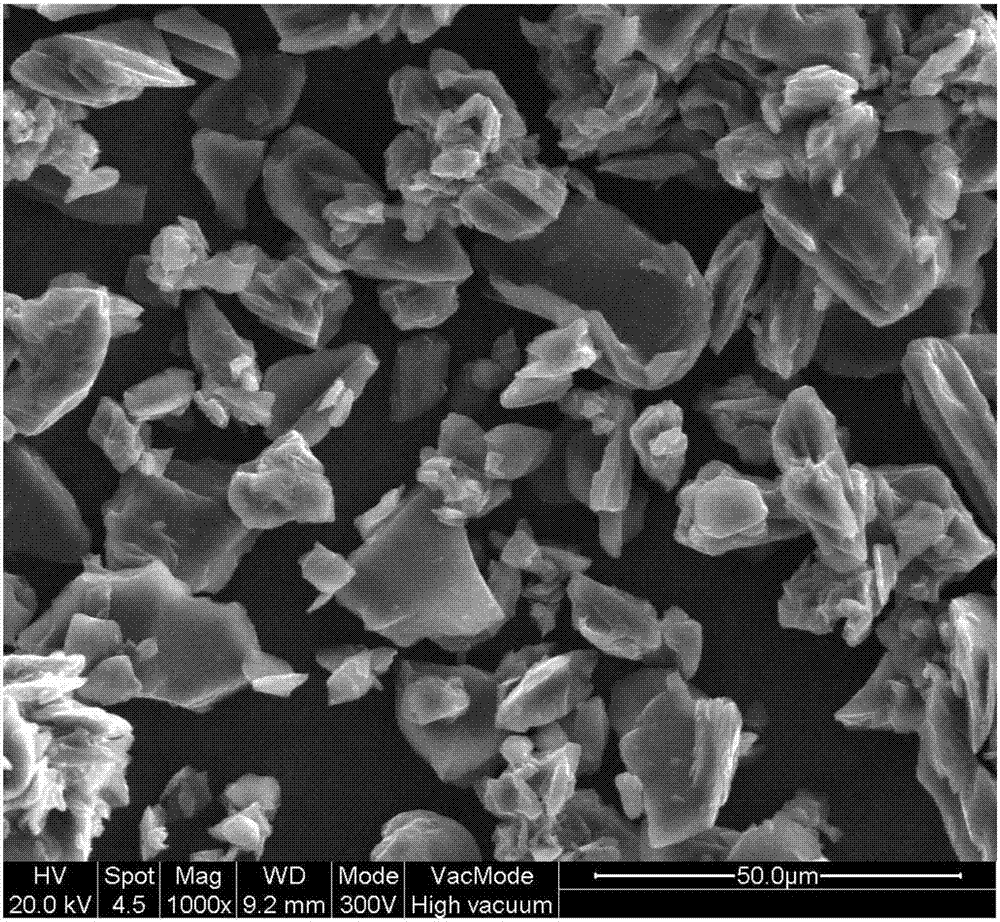

[0026] Step 2. Add 220 g of artificial graphite fine powder to the prepared mixed solution, the artificial graphite fine powder is subdivided by artificial graphite with a D50 of 10.7 μm, and ultrasonically stirred evenly to form a suspension;

[0027] Step 3. When the temperature of the suspension is lower than 40°C, add 100g of epichlorohydrin, transfer the mixture to a four-necked flask, and turn on the stirrer to react. The reaction is divided into seven stages: 57±4°C for 15 minutes; 70 React at ±3°C for 15 minutes; at 80±3°C for 30 minutes; at 85±3°C for 10 minutes; at 90±3°C for 10 minutes; at 95±2°C for 20 minutes; at 97±2°C for 20 minutes to obtain the reaction product;

[0028] Step 4, washing the reaction product in step 3 to neutrality, and then dehydrating under vacuum at -0.095MPa to obtain a hard carbon / g...

Embodiment 2

[0031] Step 1. Weigh 120g of bisphenol A and weigh 420ml of NaOH solution with a mass concentration of 5%, mix and stir at 50°C for 10-15min until dissolved;

[0032] Step 2, adding 200 g of artificial graphite fine powder to the prepared mixed solution, the artificial graphite fine powder is subdivided by artificial graphite with a D50 of 10.7 μm, and stirred evenly by ultrasonic to form a suspension;

[0033] Step 3. When the temperature of the suspension is lower than 40°C, add 90g of epichlorohydrin, transfer the mixture to a four-necked flask, and turn on the stirrer to react. The reaction is divided into seven stages: 57±4°C for 15 minutes; 70 React at ±3°C for 15 minutes; at 80±3°C for 30 minutes; at 85±3°C for 10 minutes; at 90±3°C for 10 minutes; at 95±2°C for 20 minutes; at 97±2°C for 20 minutes to obtain the reaction product;

[0034] Step 4, washing the reaction product with water to neutrality and dehydration to obtain a hard carbon / graphite composite electrode ma...

Embodiment 3

[0037] Step 1. Weigh 150g of bisphenol A and weigh 1000ml of NaOH solution with a mass concentration of 2%, and mix and stir at 50°C for 10-15min until dissolved;

[0038] Step 2, adding 160g of artificial graphite fine powder to the prepared mixed solution, the artificial graphite fine powder is subdivided by artificial graphite with a D50 of 10.7 μm, stirred evenly by ultrasonic to form a suspension;

[0039] Step 3. When the temperature of the suspension is lower than 40°C, add 110g of epichlorohydrin, transfer the mixture to a four-necked flask, and start the stirrer to react. The reaction is divided into seven stages: 57±4°C for 15 minutes; 70 React at ±3°C for 15 minutes; at 80±3°C for 30 minutes; at 85±3°C for 10 minutes; at 90±3°C for 10 minutes; at 95±2°C for 20 minutes; at 97±2°C for 20 minutes to obtain the reaction product;

[0040] Step 4, washing the reaction product with water to neutrality and dehydration to obtain a hard carbon / graphite composite electrode mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com