A kind of preparation method of oct catheter tip

A catheter tip and distal technology, which is applied in the field of OCT catheter tip preparation, can solve the problems of increasing the risk of unfavorable blood vessels, increasing the risk of unfavorable blood, and unsmooth end surfaces, etc., achieving easy operation of the preparation method, winning operation time, and tip hardness Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

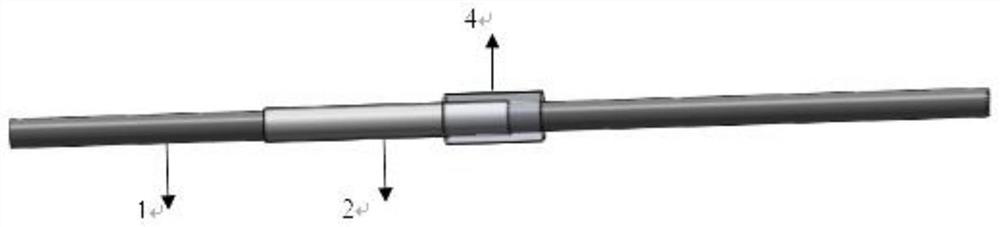

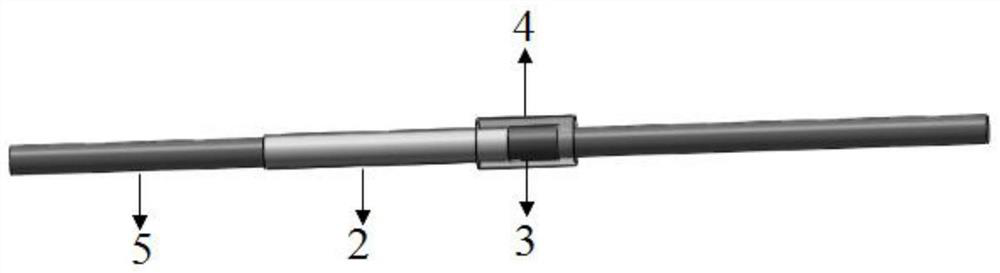

[0030] refer to Figure 1-Figure 3 As shown, the present application provides a method for preparing an OCT catheter tip, comprising the following steps:

[0031] Step 1: preprocessing, heat shrinking the diameter of one end of the imaging window tube 2 to a preset value;

[0032] Step 2: Welding integration, welding the heat-shrinked end of the imaging window tube 2 and the distal marking tube 3 into one body.

[0033] The diameter of one end of the imaging window tube 2 is heat-shrinked to be consistent with the diameter of the distal marking tube 3 by pre-processing, and then the end of the pre-processed imaging window tube 2 is welded to the distal marking tube. 3. The welding is integrated, and the inner wall of the butt joint is guaranteed to have a consistent and smooth diameter after welding, so that the OCT catheter tip can be smoothly carried out when inserting or withdrawing the guide wire, which greatly saves the operation time and reduces the possible risks of th...

Embodiment 1

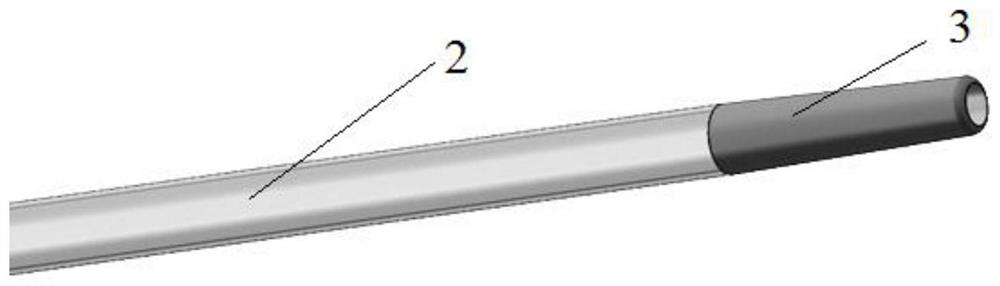

[0050] Set the imaging window tube on the first mandrel (the length of the first mandrel is twice the length of the imaging window tube), and then set the heat shrinkable tube on the to-be-treated end and the first mandrel of the imaging window tube. On a mandrel, the imaging window tube and the first mandrel section covered with the heat shrinkable tube are placed in the mold hole of the heat welding machine for heating, the heating temperature is 190°C, and the heating time is 5s. The heat-shrinkable tube shrinks and transfers heat to the imaging window tube, so that the inner diameter of the end of the imaging window tube sleeved with the heat-shrinkable tube is the same as the diameter of the first mandrel, and finally the heat-shrinkable tube and the first mandrel are removed. Mandrel.

[0051] Both the pretreated imaging window tube and the distal end marker tube are sleeved on the second mandrel, the end face of the distal end marker tube is connected to the pretreated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com