Stepping laser welding device for welding resistance wires

A laser welding, step-by-step technology, used in laser welding equipment, welding/welding/cutting items, auxiliary devices, etc., can solve the problems of weak solder joints, unstable resistance value, etc. The effect of stable value, ensuring robustness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

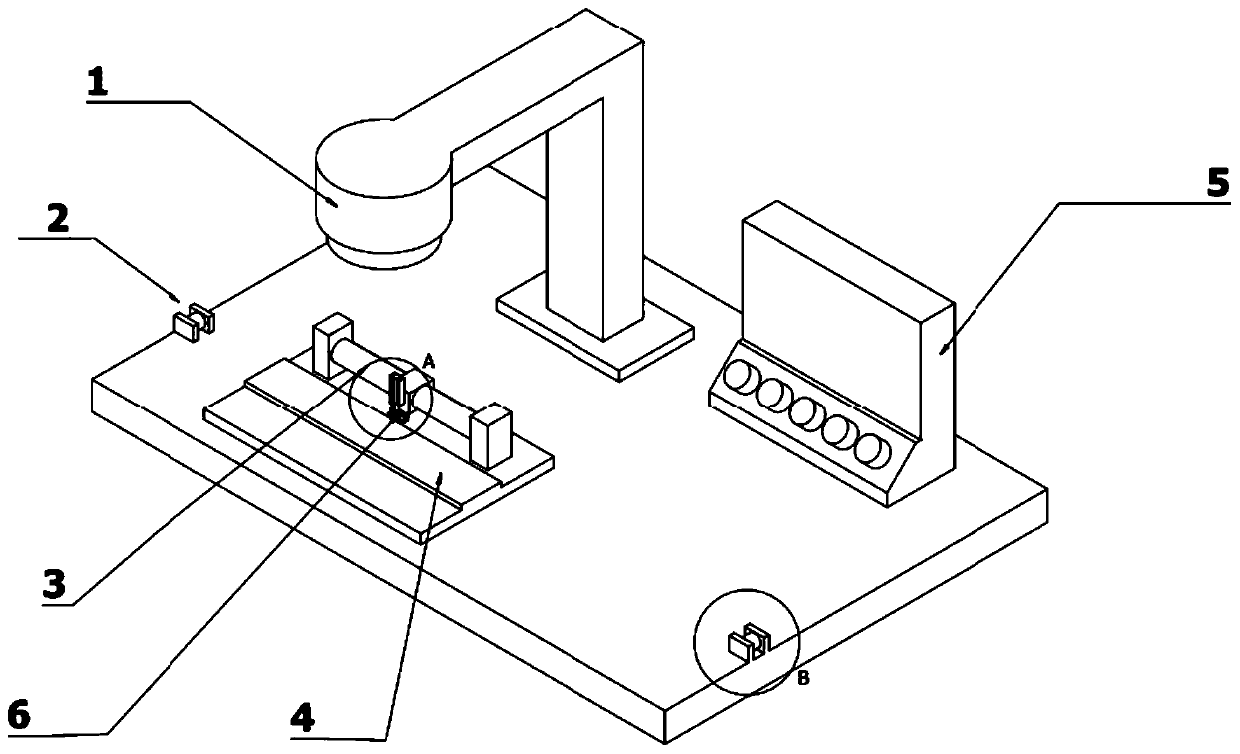

[0026] This embodiment provides a step-by-step laser welding device for welding resistance wires, such as image 3 As shown, it includes a laser welding machine 1, a vibrating mirror, a feeding guide device 2, a stepping feeding cylinder 3, a welding backing plate 4, a controller 5 and a clamping device 6.

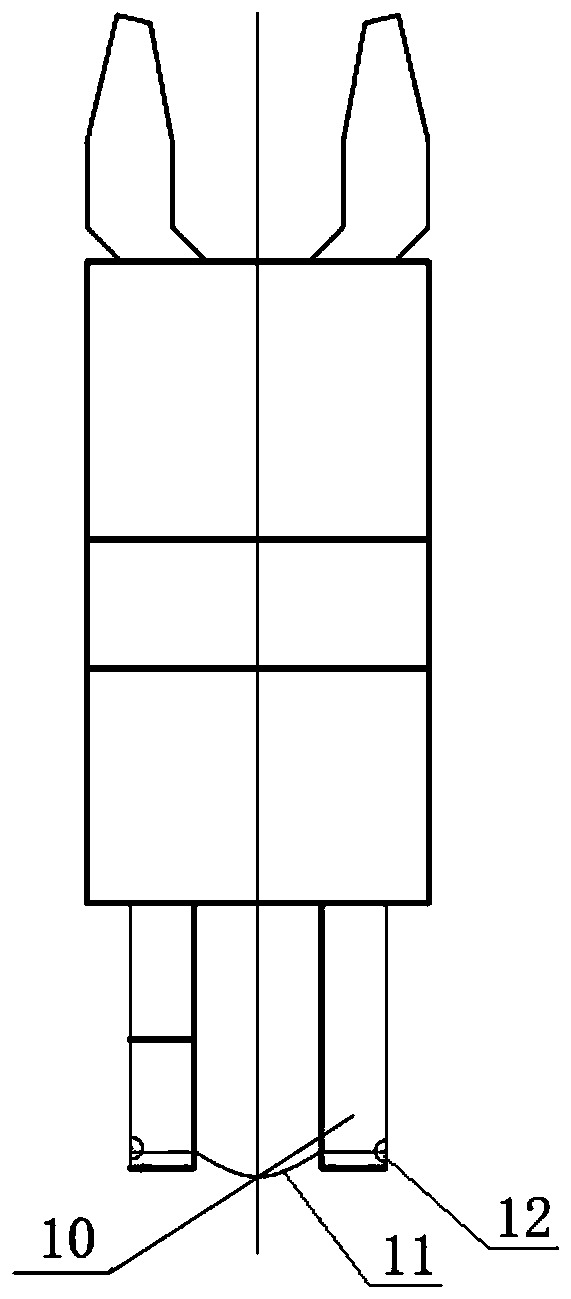

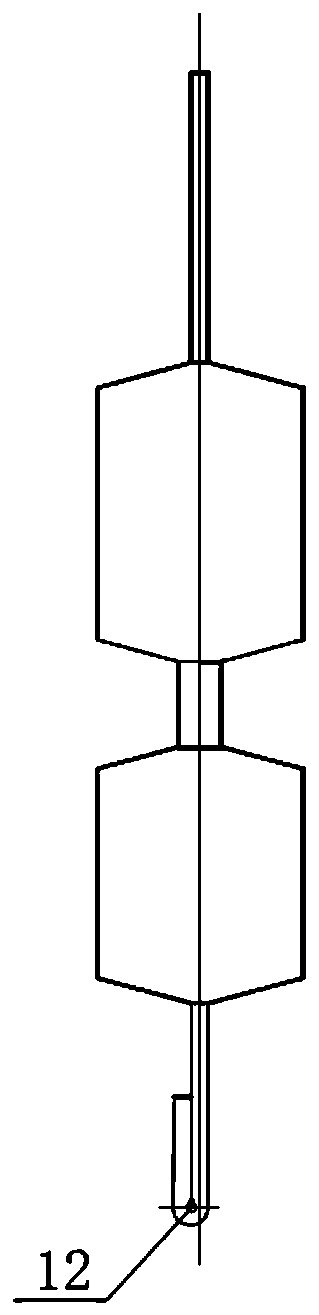

[0027] The welding object is the electrode frame belt, such as figure 1 , figure 2 As shown, the same end of the two electrodes clamps the same resistance wire 11 to form an electrode frame 10, and the electrode frame 10 formed on the base material along the straight line is the electrode frame belt; the clamping place 12 of the resistance wire is the part to be welded . The base material is copper alloy, or tin-plated copper alloy, or nickel-copper alloy, or carbon steel, or / and stainless steel; when the base material is a strip, the thickness ran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com