Preparation method of micron silicon-carbon composite negative electrode material with long cycle life

A silicon-carbon composite and negative electrode material technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of increasing the specific surface area of materials, restricting cycle stability, and integrity of difficult electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

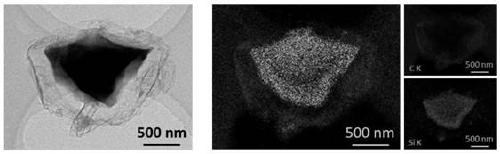

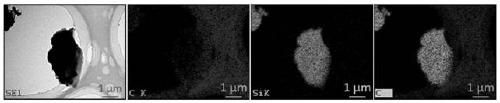

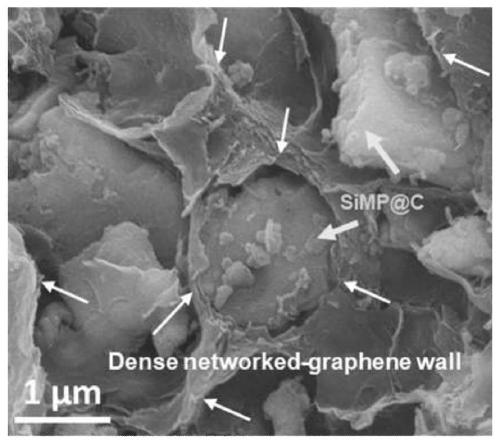

Image

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing a micro-silicon-carbon composite negative electrode material with a long cycle life, comprising the following steps:

[0030] 1) Place 1.0 g of silicon powder with a particle size distribution range of 3 μm to 5 μm in the crucible, transfer it to a tube furnace, and heat up at a rate of 10 ºC / min under an argon flow rate of 50 mL / min Heating to 1000 ºC, and then feeding methane gas at this temperature with a flow rate of 50 mL / min and a reaction time of 60 min. After the reaction, the methane gas was turned off, the argon flow was kept constant, the temperature was lowered to 400 ºC at a rate of 10 ºC / min, and then naturally cooled to room temperature to obtain carbon-coated micron silicon particles.

[0031] 2) Ultrasonic dispersion of 500 mg of micron silicon carbon particles obtained in step 1) in a mixed solvent of 100 mL of water and 100 mL of ethanol to obtain a uniform dispersion;

[0032] 3) Add 6 g of sodium hydr...

Embodiment 2

[0038] Embodiment 2: Different from Embodiment 1, the flow rate of feeding methane gas in step 1) is adjusted to 30 mL / min, and the rest are the same as Embodiment 1, and will not be repeated here.

Embodiment 3

[0039] Example 3: The difference from Example 1 is that step 1) put 1.0 g of silicon powder with a particle size distribution range of 3 μm to 5 μm in the crucible, transfer it to a tube furnace, and heat it under 40 mL / min of argon Under the air flow, the heating rate was 7 ºC / min to 950 ºC, and then methane gas was introduced at this temperature, the flow rate was 50 mL / min, and the reaction time was 40 min. After the reaction, the methane gas was turned off, the argon flow was kept constant, the temperature was lowered to 400 ºC at a rate of 7 ºC / min, and then naturally cooled to room temperature to obtain carbon-coated micron silicon particles.

[0040] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Block density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com