Air-stable layered transition metal oxide positive electrode material and sodium ion battery thereof

A transition metal and cathode material technology, applied in the field of electrochemical energy, can solve the problems of harsh electrode fabrication conditions, rapid material capacity decay, irreversible phase transition, etc., and achieve the effects of inhibiting multiphase transformation reactions, high repeatability, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

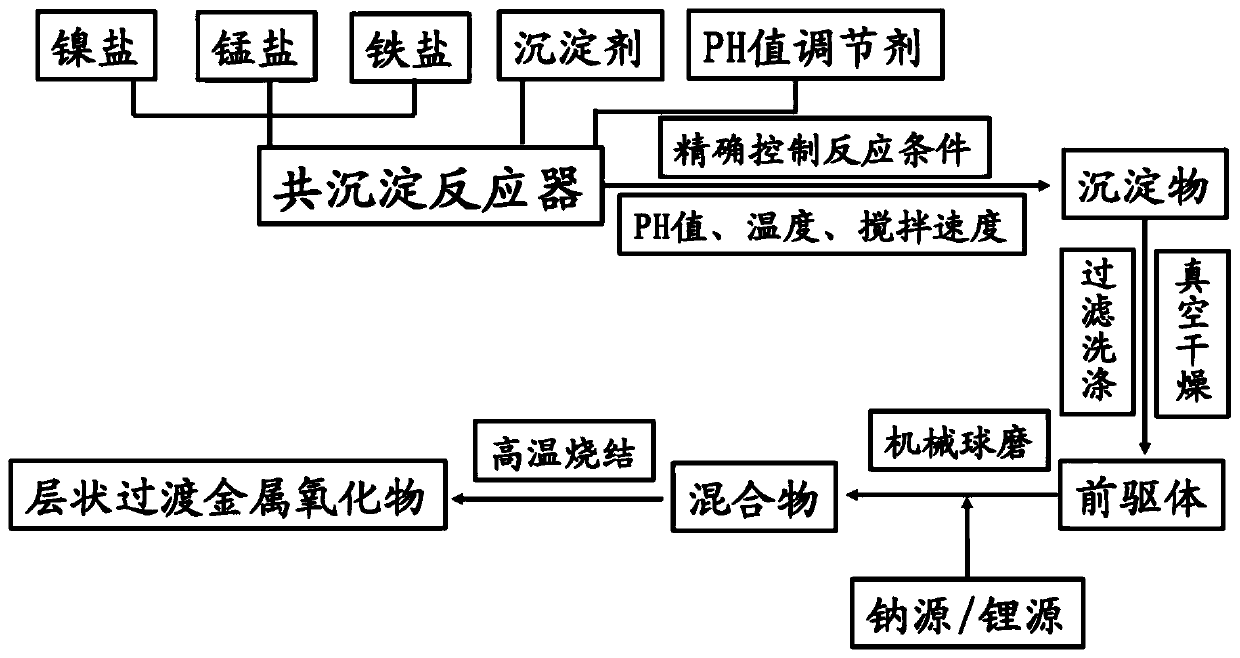

[0022] In the second aspect, an embodiment of the present invention provides a method for preparing a layered transition metal oxide positive electrode material. The preparation method used is one of hydroxide co-precipitation, carbonate co-precipitation, and oxalate co-precipitation, specifically include:

[0023] Pump the mixed solution of manganese salt, nickel salt and iron salt and the precipitant solution into the reactor at the same time through the peristaltic pump, control the solution drop rate to 2-10ml / min, the pH value during the reaction is 7.5-11, and the reaction temperature is 40 -80°C, the stirring speed is 500-1000rmp, to obtain a uniform spherical precursor powder; the precipitation agent solution includes one of the hydroxide precipitation solution, the carbonate precipitation solution or the oxalate precipitation solution; the molar stoichiometric ratio The spherical precursor powder is weighed and uniformly mixed with one or both of the sodium source and...

Embodiment 1

[0025] see figure 1 , figure 1 It is a schematic flow chart of a method for preparing an air-stable layered transition metal oxide cathode material provided by the present invention. Specifically, the method for preparing the layered transition metal oxide cathode material may include:

[0026]The mixed solution of manganese sulfate, nickel sulfate, ferric sulfate and sodium hydroxide solution are pumped into the reactor to stir at the same time through a peristaltic pump. Atmosphere, the reaction temperature is 50 ° C, after the reaction is complete, let it stand for 2 hours, centrifuge, filter, wash, and dry to obtain spherical precursor powder; weigh the spherical precursor powder and sodium carbonate according to the molar ratio and mix them evenly, and Sintered at 800°C for 10 hours to obtain NaMn 0.67 Ni 0.13 Fe 0.2 o 2 .

Embodiment 2

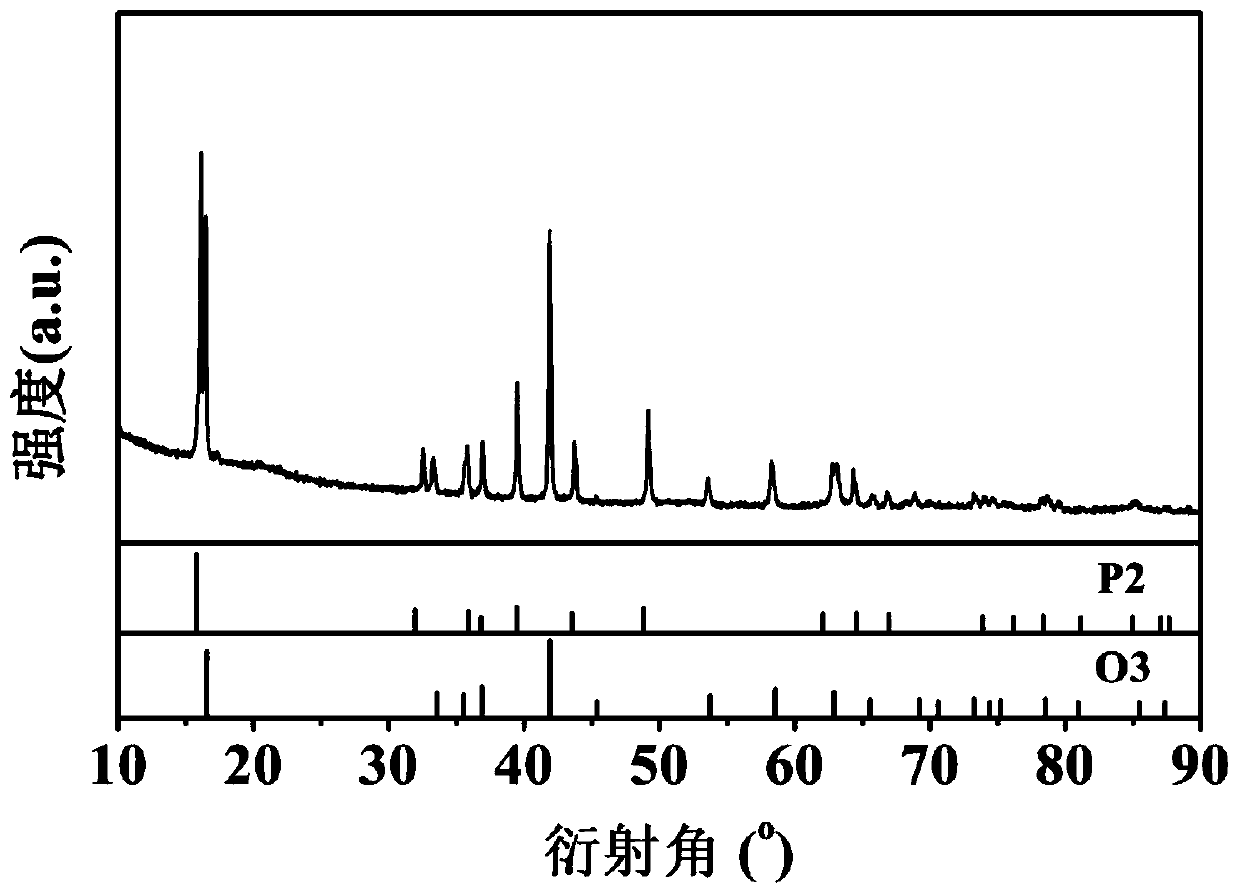

[0028] according to figure 1 The preparation method process shown, obtains Na 0.85 Li 0.15 (Mn 0.67 Ni 0.13 Fe 0.2 ) 0.85 o 2 . Such as figure 2 As shown, the material has a spherical shape, and the particle size is 2-8 μm. XRD test results show as image 3 As shown, the material is an intergrown phase of P2 and O3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com