Three-electrode type Pb(II) and Cu(II) electrochemical sensor, and preparation method and application thereof

A three-electrode, electrochemical technology, applied in the fields of material electrochemical variables, scientific instruments, instruments, etc., can solve the problems of inability to meet popularization, inability to realize real-time monitoring, and bulky instruments, and achieve good recovery rate and potential application range. , The effect of high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Using the glassy carbon electrode as the working electrode, based on the three-electrode working system to produce Pb 2+ and Cu 2+ Electrochemical sensors, and test sensor-related performance, the specific process is as follows:

[0041] 1. Grinding the glassy carbon electrode: Before grinding the glassy carbon electrode, gently wipe the glassy carbon electrode with moistened absorbent cotton to remove dirt and ensure that the surface of the electrode is smooth; take a little 0.05μm polishing powder Al 2 o 3 Put it on the suede, then drop a small amount of deionized water, and stir it evenly with the polishing powder; hold the glassy carbon electrode firmly to ensure that the glassy carbon electrode is always vertically moving in a circular or "8" shape. Rotate clockwise and counterclockwise 100 times until the surface of the glassy carbon electrode appears mirror-like, and rinse with deionized water. The state of the glassy carbon electrode was detected by cyclic vo...

Embodiment 2

[0044] Use ZIF-67 as the electrode modification material to modify the glassy carbon electrode (GCE), that is, ZIF-67 / GCE as the working electrode, and make Pb 2+ and Cu 2+ Electrochemical sensor, its fabrication process is:

[0045] 1. The process of polishing the glassy carbon electrode is the same as that in Example 1.

[0046]2. Fabrication of ZIF-67 / GCE working electrode: first, ZIF-67 nanomaterials were prepared.

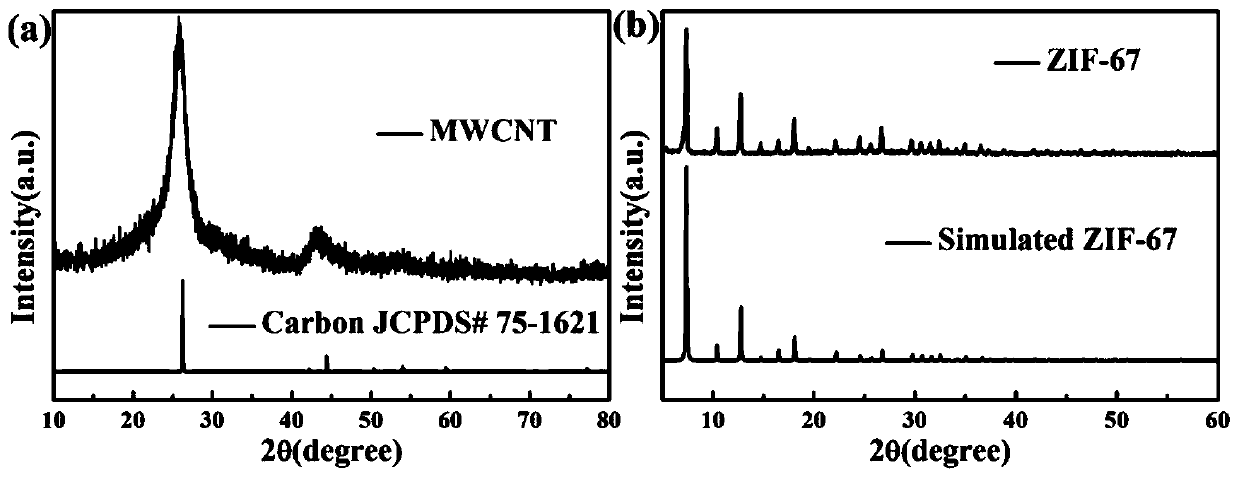

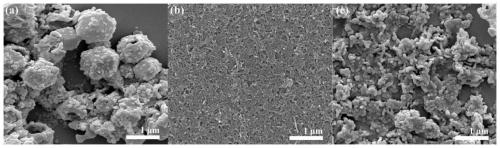

[0047] Weigh 4mmol Co(NO 3 ) 2 ·6H 2 O and 16mmol 2-methylimidazole, they were dissolved in the methanol of 100mL respectively, stirred evenly, then Co(NO 3 ) 2 The solution was poured into 2-methylimidazole, mixed and stirred evenly, and left to stand for 24 hours; the product was filtered with a microporous membrane, and finally dried at 30° C. for 24 hours to obtain ZIF-67 powder.

[0048] Use ZIF-67 as the electrode modification material, and modify it on the glassy carbon electrode: take 3 mg of ZIF-67 powder, add 2.4 mL of deionized water, and son...

Embodiment 3

[0051] Use ZIF-67 and MWCNT as electrode modification materials to modify glassy carbon electrode (GCE), that is, ZIF-67 / MWCNT / GCE as working electrode, and make Pb 2+ and Cu 2+ Electrochemical sensor, its fabrication process is:

[0052] 1. The process of polishing the glassy carbon electrode is the same as that in Example 1.

[0053] 2. Making ZIF-67 / MWCNT / GCE working electrode: first prepare ZIF-67 nanomaterials and pretreat MWCNT.

[0054] The preparation process of the ZIF-67 nanometer material is the same as in Example 2. The MWCNT pretreatment process is as follows: first, add 0.4gMWCNT to 20mL mixed concentrated sulfuric acid and concentrated nitric acid (the volume ratio of concentrated nitric acid and concentrated sulfuric acid is 1:3, and the mass fractions of concentrated nitric acid and concentrated sulfuric acid are 68% and 98% respectively) mixed acid solution. The suspension was then refluxed for 6 hours at 40°C with continuous stirring. It is then rinsed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com